Automatic edge trimming machine

An edge trimming machine and automatic technology, applied in the details of milling machine equipment, metal processing equipment, milling machine equipment, etc., can solve the problems of physical damage to operators, high defect rate, and easy-to-handle environment, and achieve quality assurance and edge trimming speed Fast, the effect of protecting the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

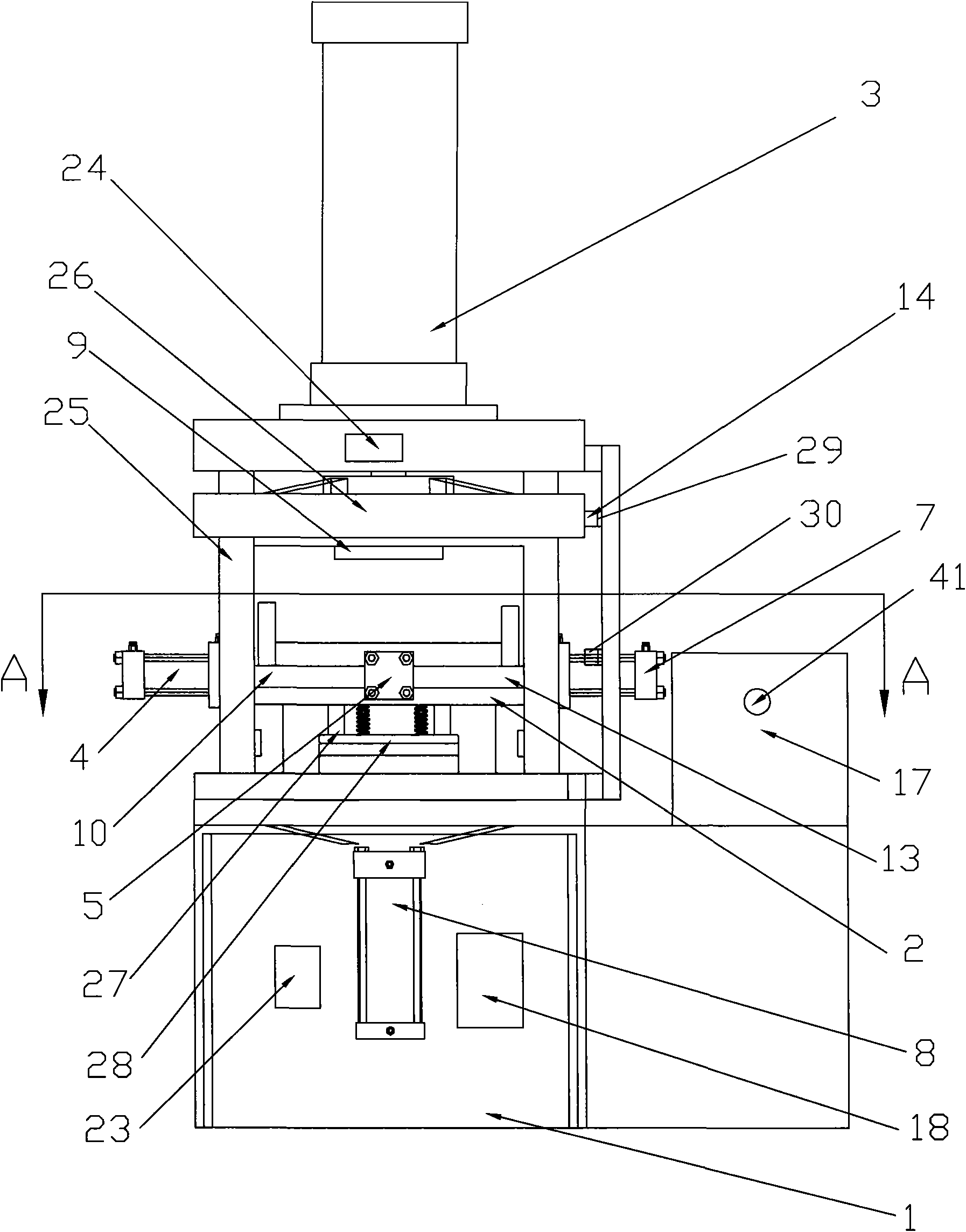

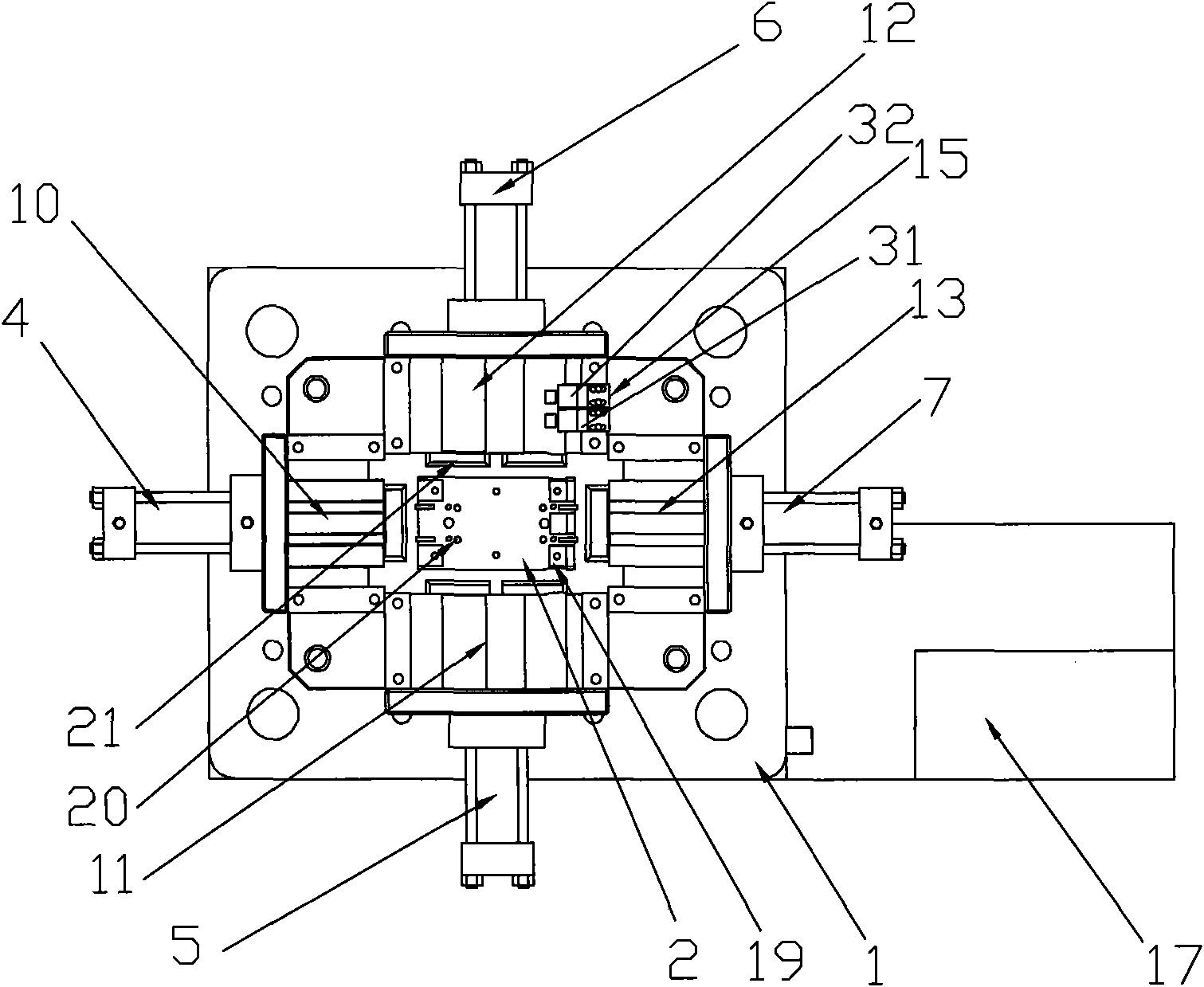

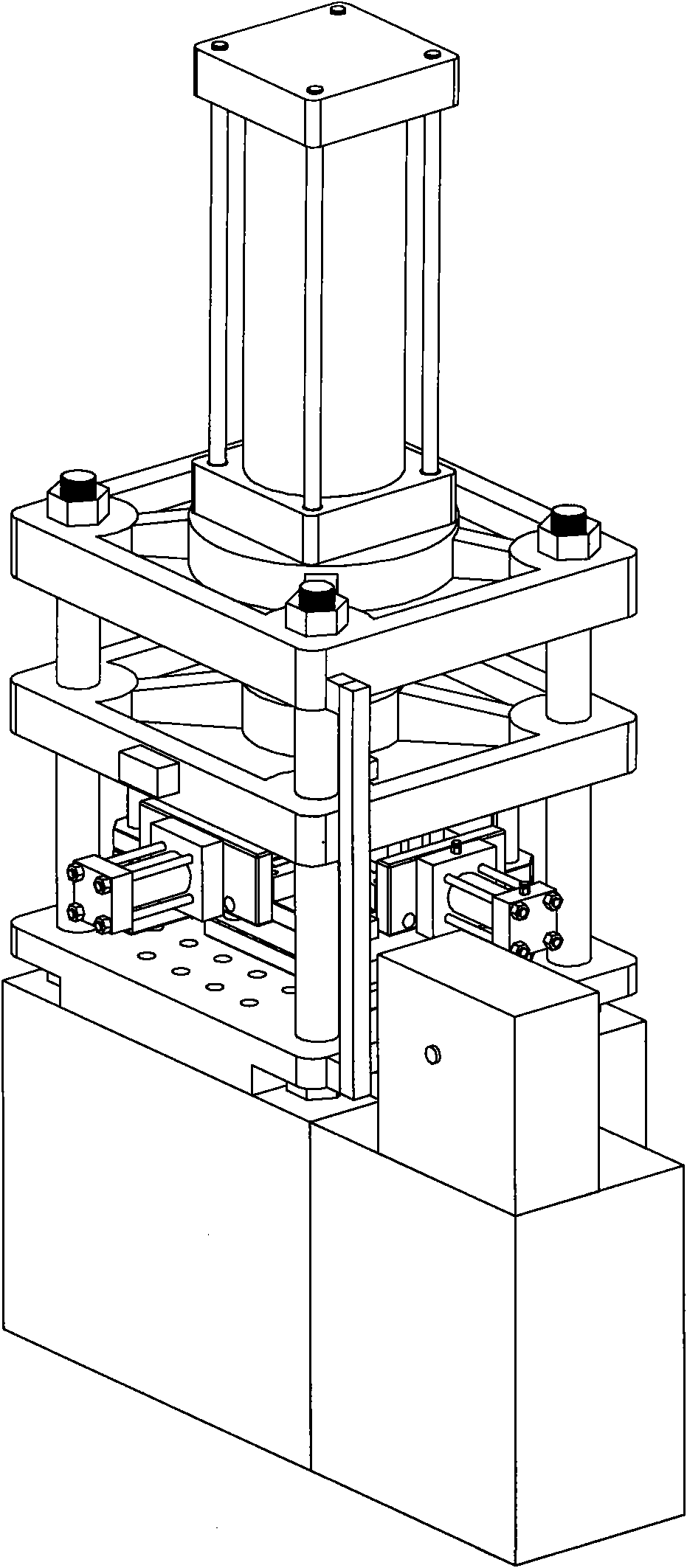

[0018]Embodiment: an automatic trimming machine, including frame 1, cold mold 2, first, second, third, fourth, five, six cylinders 3, 4, 5, 6, 7, 8, first, second, third , four, five knives 9, 10, 11, 12, 13, first and second pairs of travel switches 14, 15, console 17, cylinder controller 18 and first, second, third, fourth, fifth, and sixth solenoid valves 35 . 8 is vertically fixed on the frame 1 below the cold mold 2, and the second, fifth, third, and fourth cylinders 4, 7, 5, and 6 are respectively fixed on the front, rear, left, and right sides of the cold mold 2. On the frame 1, the piston rods of the first, second, third, fourth, and fifth cylinders 3, 4, 5, 6, and 7 are detachably fixed with the first, second, third, fourth, and fifth knives 9, 10, 11, 12, 13, the first and second pairs of travel switches 14, 15 are respectively fixed on the frame 1, the first pair of travel switches 14 can sense the position of the first knife 9, and the second pair of travel switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com