On-line detection and fault display method of LED

A fault display and fault technology, which is applied in the field of LED online detection and fault display, can solve the problems of low efficiency, low accuracy, and stoppage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

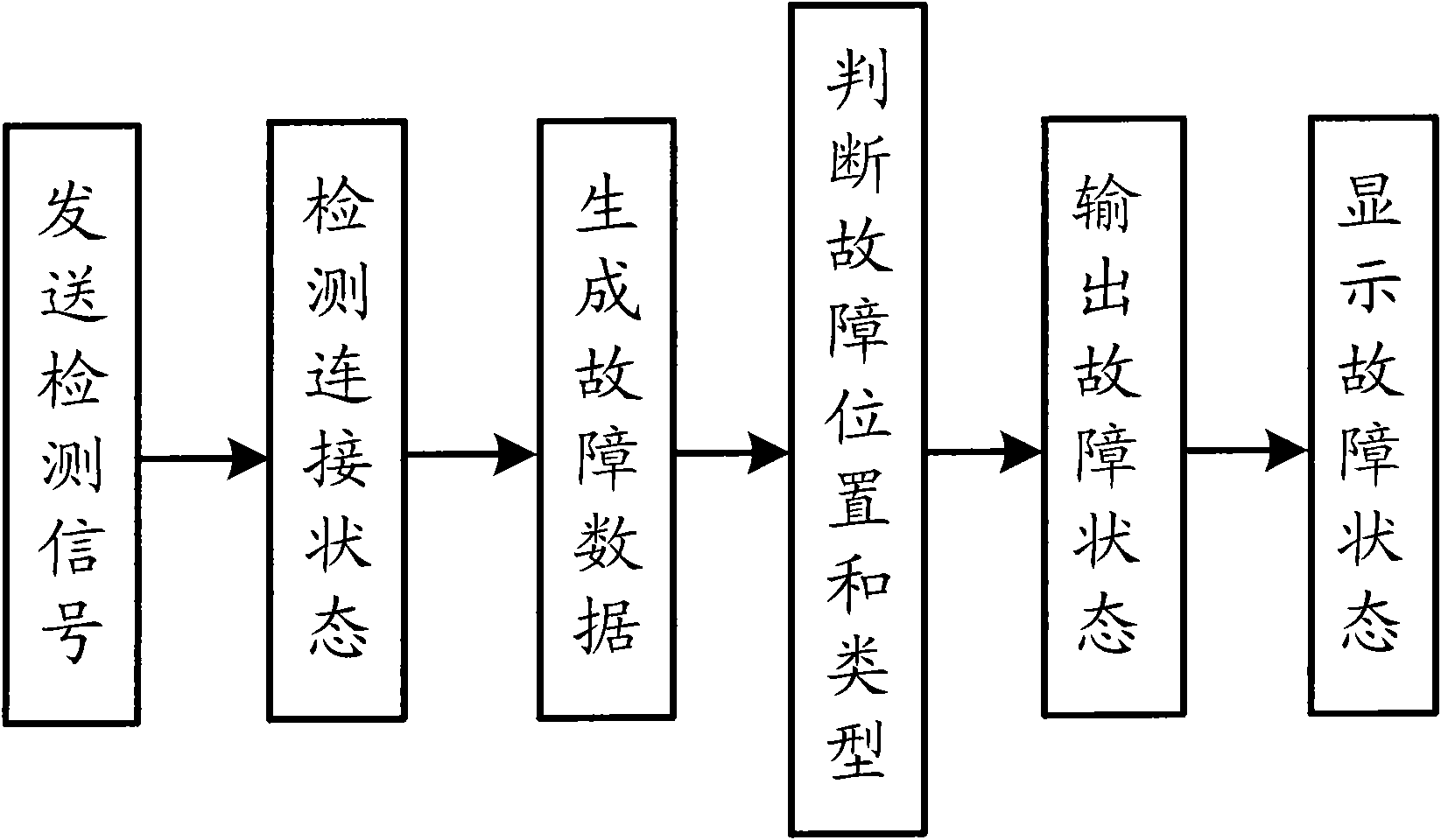

[0021] Such as figure 1 As shown, this embodiment provides an LED online detection and fault display method. First, a detection signal is sent to the set detection module. The detection signal is a signal to start the online detection. The signal can be a wired electrical signal. Transmission through lines; or, the signal can also be a wireless signal, through wireless transmission, for example, send a remote control signal through a remote controller, thereby starting the online detection module to detect each unit of the display terminal; The signal starts the inspection of the display terminal, and the detection is very convenient.

[0022] For example, when it is necessary to detect whether the storage of the display terminal is faulty, the online detection function can be started, or, when it is found that the storage of the display terminal is abnormal, the online detection function can be started, and the online detection can be confirmed. Displays whether the terminal...

Embodiment 2

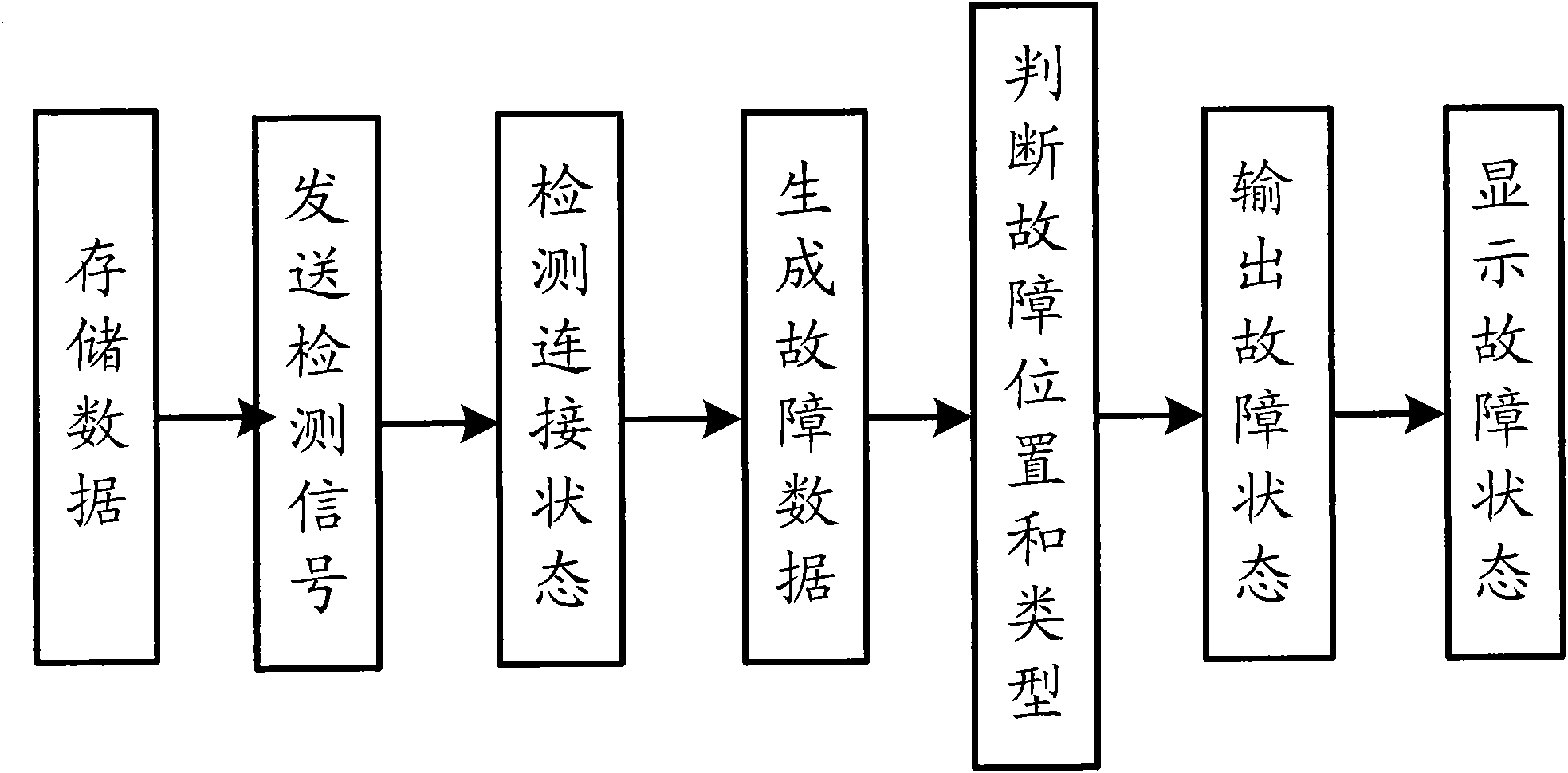

[0040] Such as figure 2 As shown, on the basis of the above examples, in the LED online detection and fault display method provided by this embodiment, before detecting the electrical connection status and signal connection status of each component of the display terminal, the display terminal is also stored structure data.

[0041] For example, the structural data includes the units that make up the display terminal, such as the interconnection position data of each control chip, each driver chip, and each LED, the circuit connection structure data between each unit, and the signal line between each unit Connection structure data, wherein the signal connection structure includes the cascade control signal connection structure between the control chips, the electrical signal connection structure between the control chip and each driver chip, and the electrical signal connection between each driver chip and each LED structure.

[0042] Moreover, when the judging module judge...

Embodiment 3

[0044] Such as figure 2 As shown, on the basis of the above examples, in the LED online detection and fault display method provided by this embodiment, after storing the structural data of the display terminal, the parameter data of each LED of the display terminal is also stored, wherein , the parameter data includes the wavelength and brightness of each LED.

[0045] By storing data such as the wavelength and brightness of each LED, the target parameter data of each LED during display can be known, and by combining the actual display parameter data of each LED that can be detected by the detection module, that is, the actual display parameter data and When there is a difference in the target parameter data comparison, it can be judged that the LED is faulty, wherein the LED fault belongs to a specific type of display unit fault, for example, the control signal input by each LED has data loss, signal distortion and other faults; therefore, When the circuit connection and si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com