Electromechanical transducer device

一种感测装置、机电式的技术,应用在机械控制装置、传动装置控制、控制机构等方向,能够解决不利等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

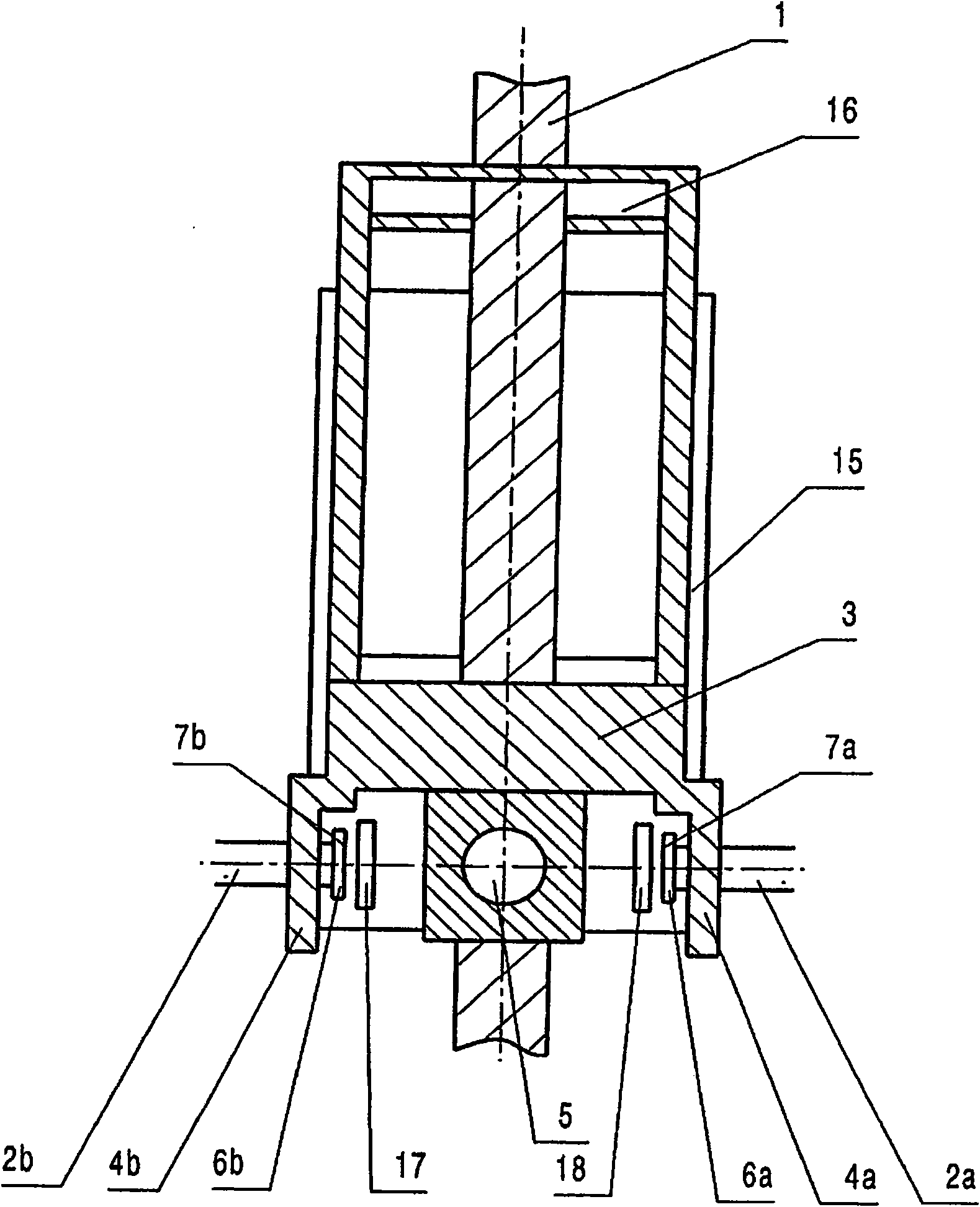

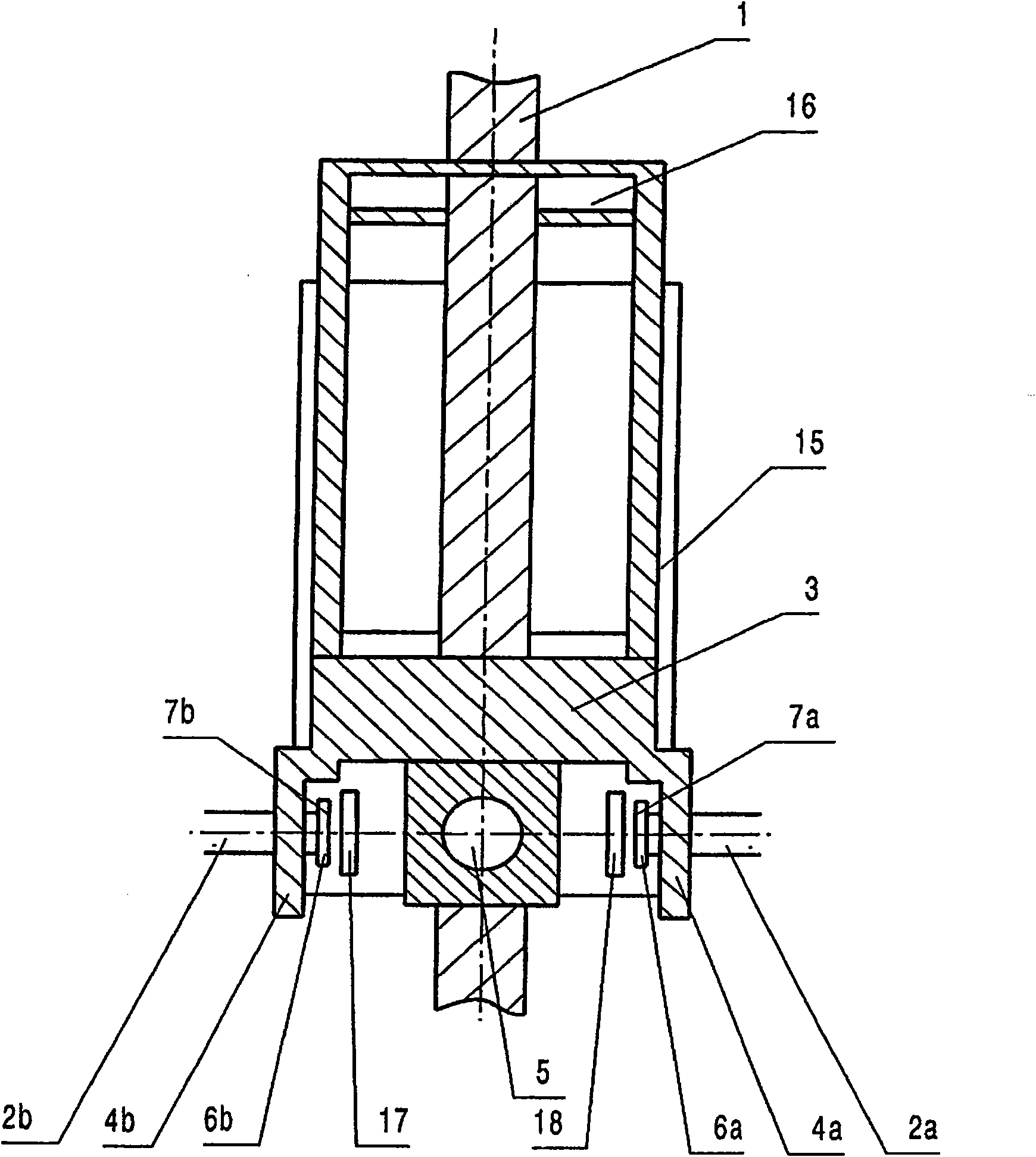

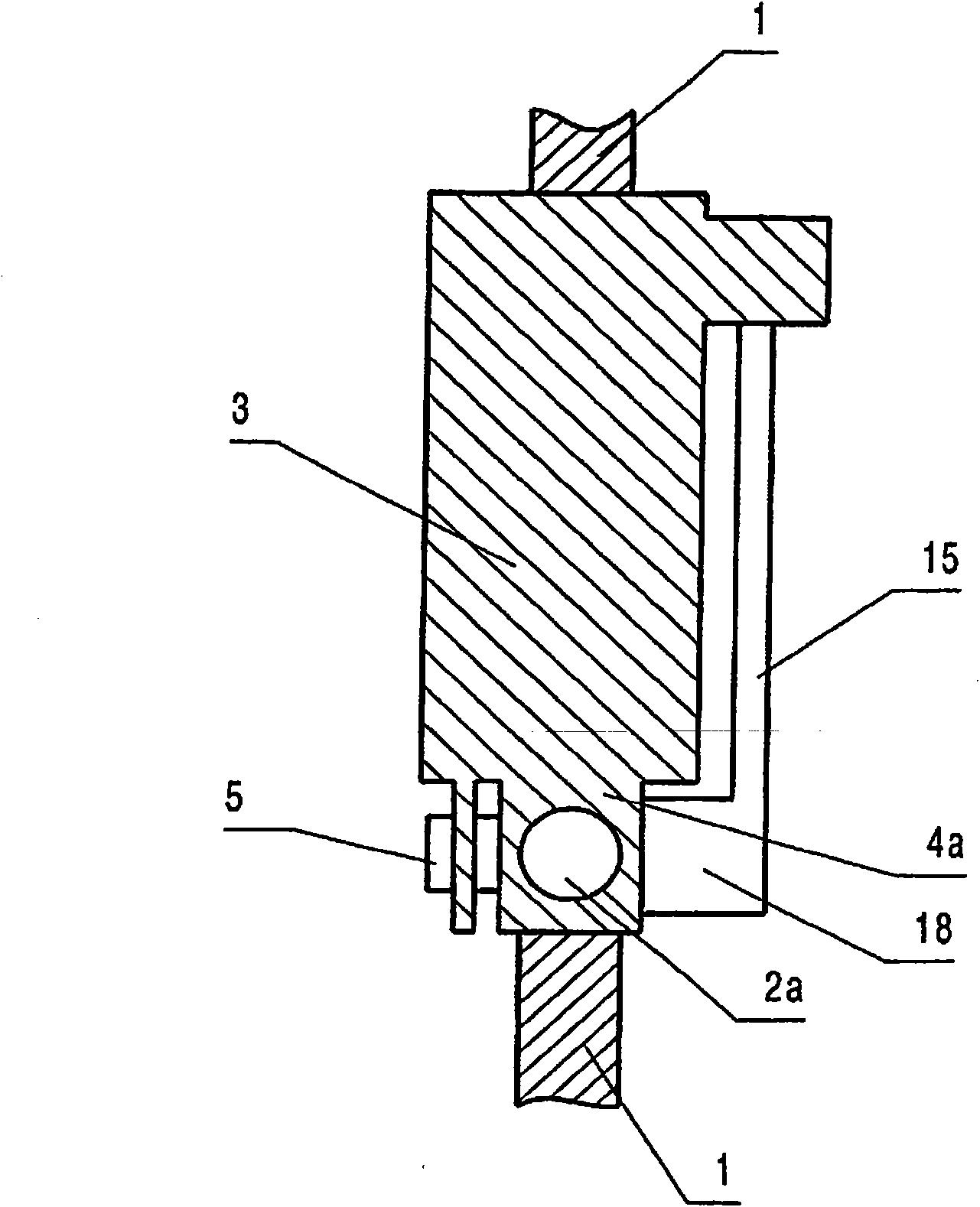

[0040] 1 to 3 illustrate a first design of the automatic transmission of the invention for a motor vehicle, wherein the shift and selector lever 1 can be positioned in two different positions with respect to the first shaft 2a, 2b and with respect to the second shaft 5. Supported for swinging in the direction. The two different pivot planes roughly define a manual shift mode and a so-called automatic channel, in which the lever can be shifted into gears P, N, R, S. The rod 1 extends through an elongated hole 16 arranged on the upper section of the suspension device 3, wherein the suspension device can be designed as a shift lever holder and has an elongated hole 16 whose longitudinal extension is parallel to First pivot axis 2a, 2b.

[0041] The suspension device 3 or the selector lever holder has bearing lugs 4a, 4b on both side ends on its lower section, which receive the free end sections of the bearing bolts 2a, 2b, whereby The suspension device 3 can be pivoted overall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com