Hub driving system with double motors

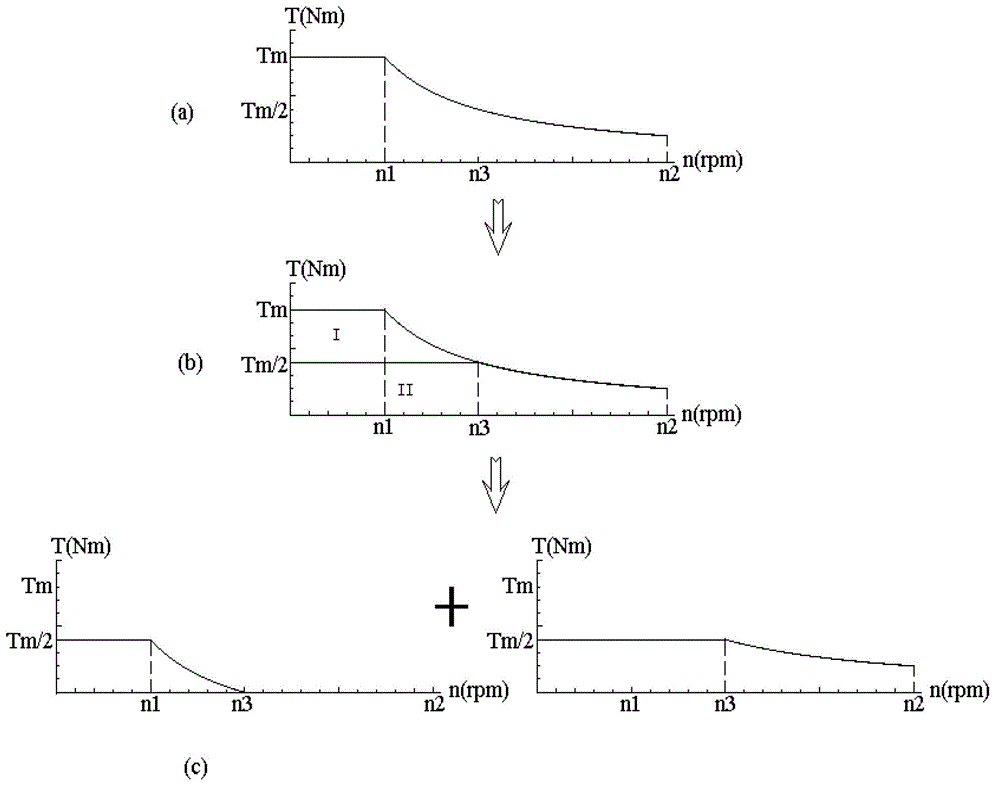

A wheel-hub drive and dual-motor technology, applied in the direction of motion deposition, power device, transportation and packaging, etc., can solve the problems of hidden safety hazards, low fail-safety, and difficult implementation, and meet the requirements of high fail-safety and speed-expansion ratio Low, high fail-safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to be able to understand the technical content of the present invention more clearly, the following embodiments are specifically described in detail. It should be understood that the embodiments are only used to illustrate the present invention, but not to limit the present invention.

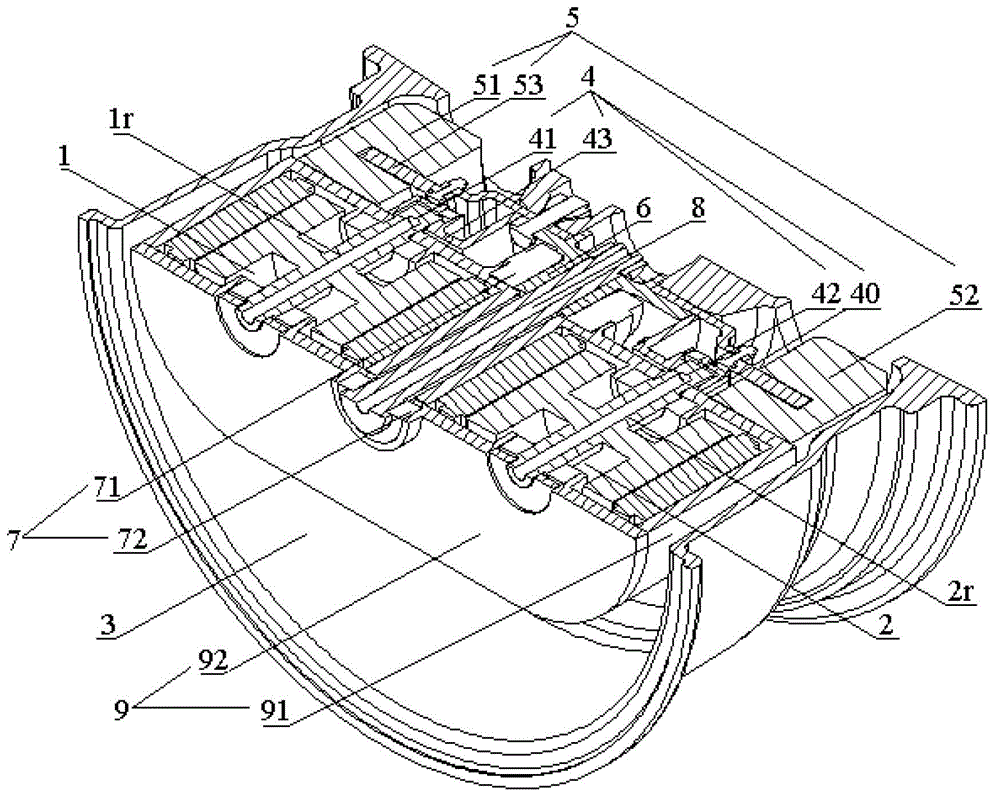

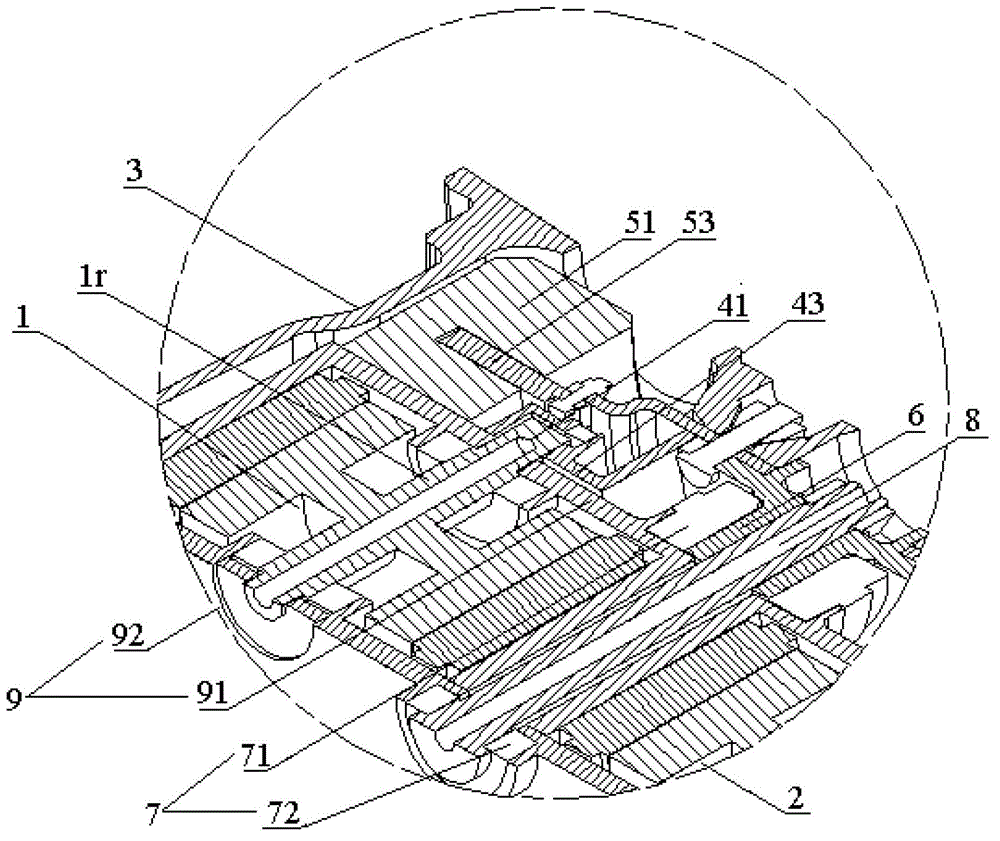

[0026] figure 1 with Figure 1a It is an axonometric partial schematic diagram and a partial enlarged schematic diagram of a specific embodiment of the present invention. reference figure 1 with Figure 1a , The wheel hub drive system with dual motors includes: a first motor 1 and a second motor 2 for providing power to drive the wheels 3; an in-wheel reducer 4 for matching the first motor 1 and the second motor 2 with The rotational speed of the wheel 3 includes the reducer housing 40, the first driving gear 41, the second driving gear 42 and the driven gear 43; the braking device 5 is used to brake the wheel 3 and includes the first brake caliper 51, the second The brake caliper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com