Ultrasonic flaw detecting method and its device

A flaw detection device, ultrasonic technology, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve problems such as difficult to detect defect echoes, unable to receive and process to form focus, etc. , to achieve the effect of reducing the dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] Embodiments of the present invention will be described below with reference to the drawings.

[0095] Figure 1 to Figure 9 One embodiment of the present invention is shown.

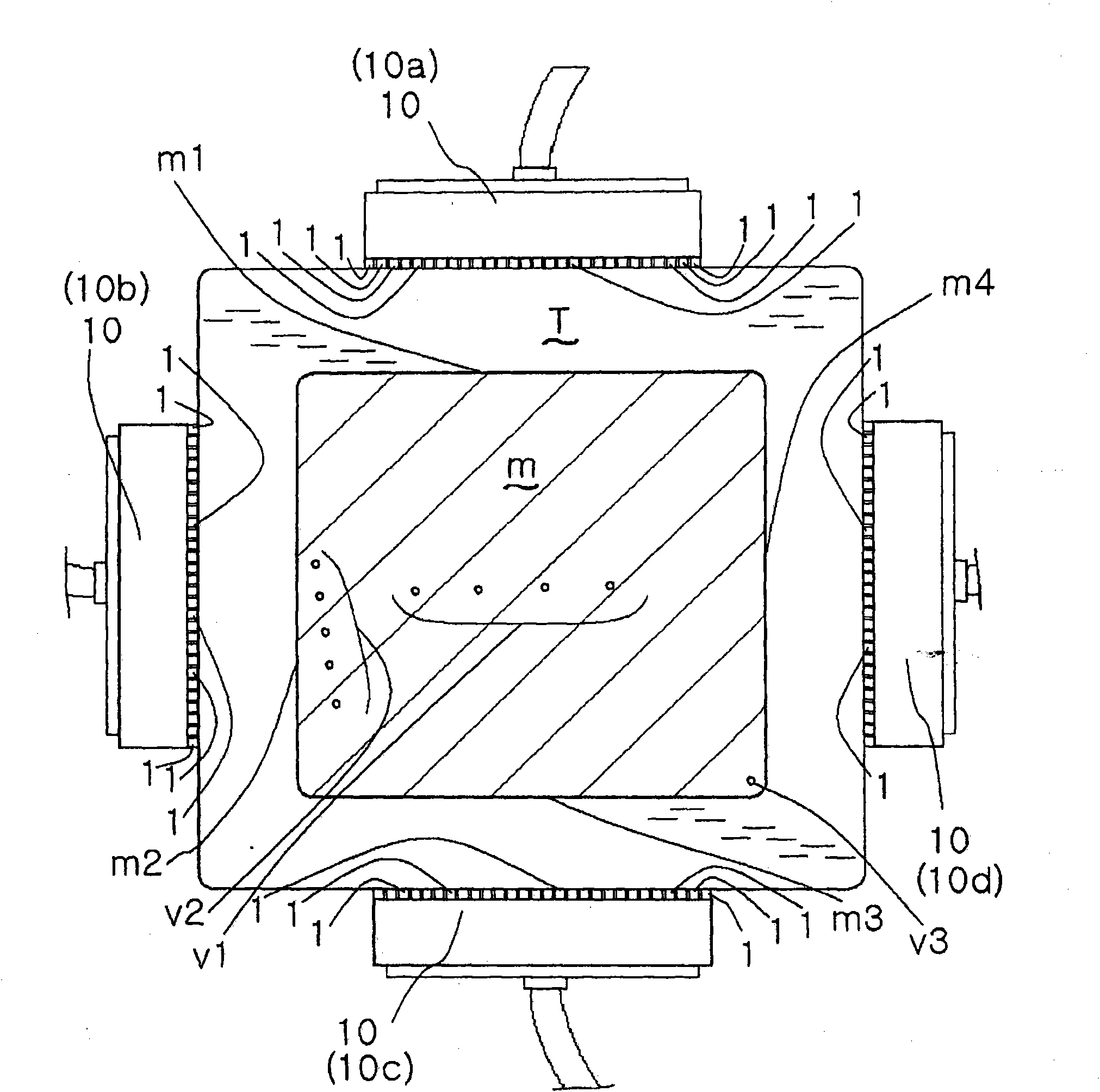

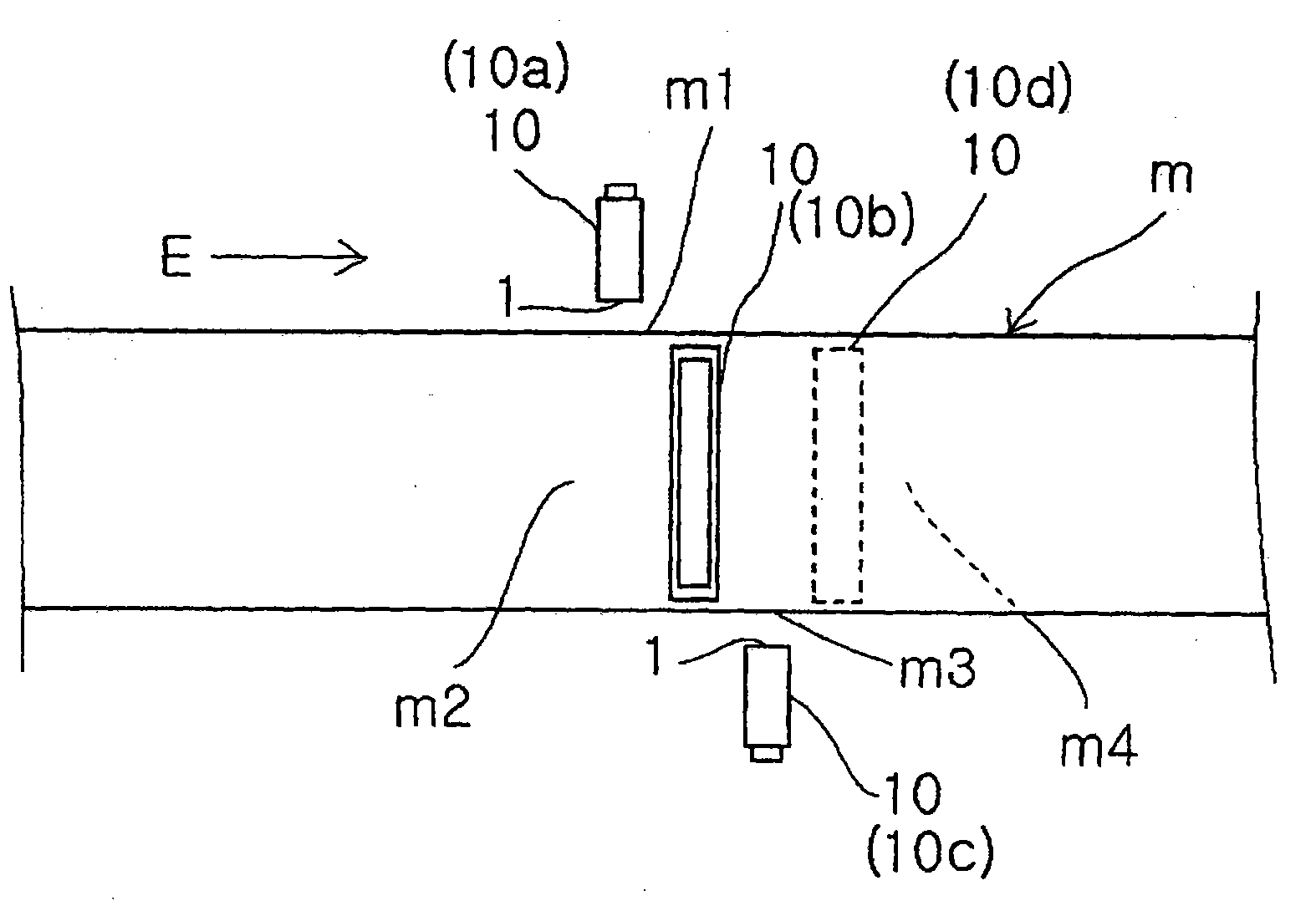

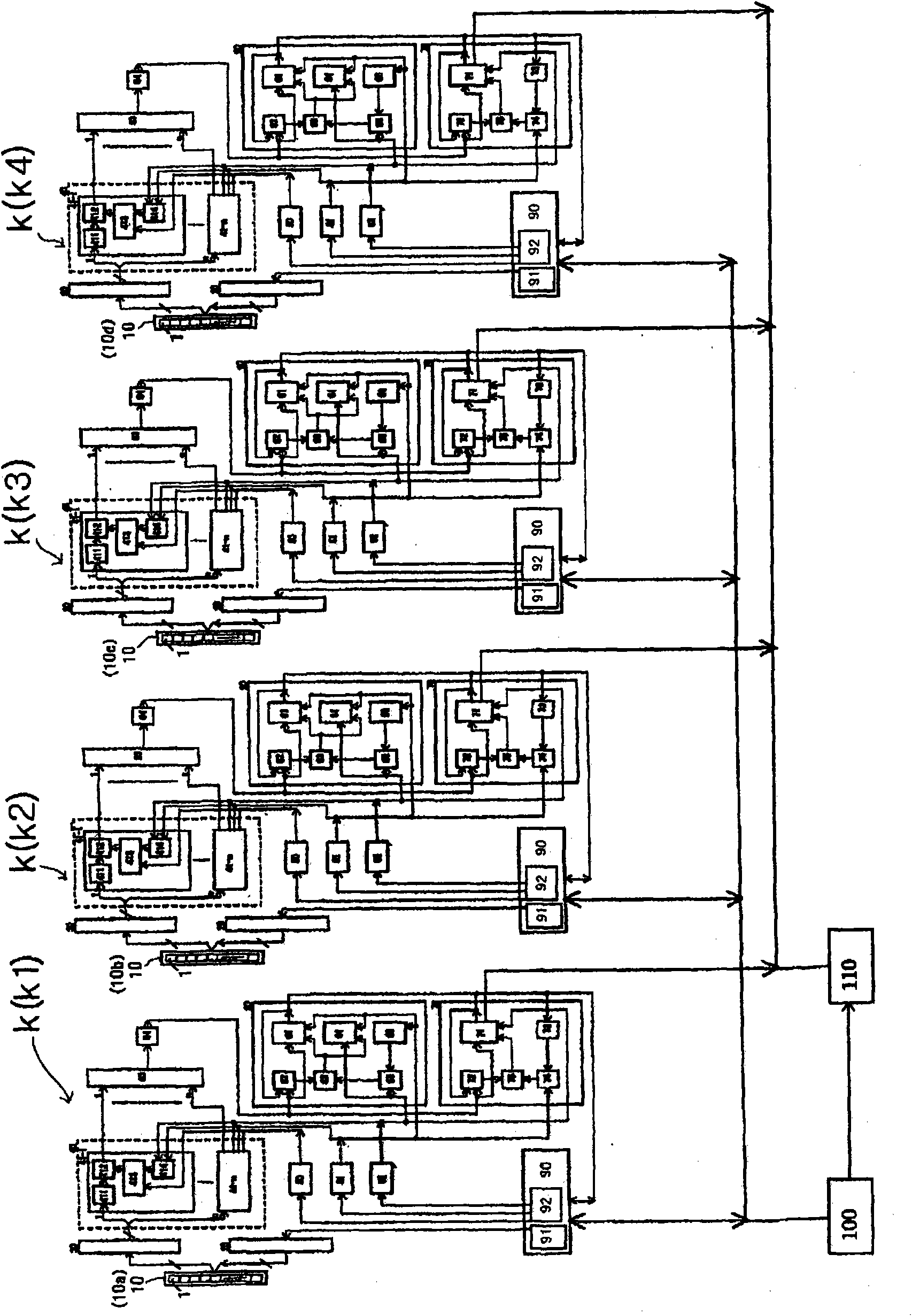

[0096] figure 1 It is a schematic cross-sectional view showing the arrangement of an array probe of a device according to an embodiment of the present invention. figure 2 It is a schematic side view showing the above arrangement. image 3 is the block diagram of the device. Figure 4 is enlarged image 3 The block diagram of the main part of the block diagram. Figure 5 It is a schematic cross-sectional view showing a state in which one array probe of the above device transmits ultrasonic waves to a test material. Figure 6 It is an explanatory drawing about the oblique flaw detection of the above-mentioned device. Figure 7 It is a flowchart showing the control procedure of the above-mentioned ultrasonic flaw detection device. Figure 8 It is an explanatory diagram showing a virtual elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com