Nuclear power evaporator heat transfer tube inner hole flaw detection device

A technology of a nuclear power evaporator and a flaw detection device, which is applied in the fields of nuclear power generation, nuclear engineering, nuclear reactor monitoring, etc., can solve problems such as difficulty in flaw detection and detection, and achieve the effects of reliable flaw detection, elimination of omissions, and improvement of accuracy and work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

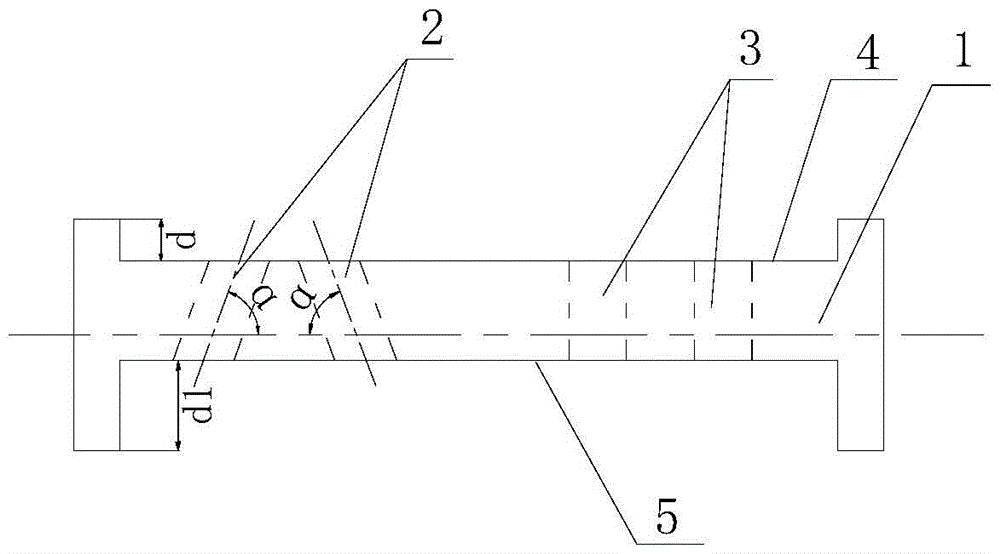

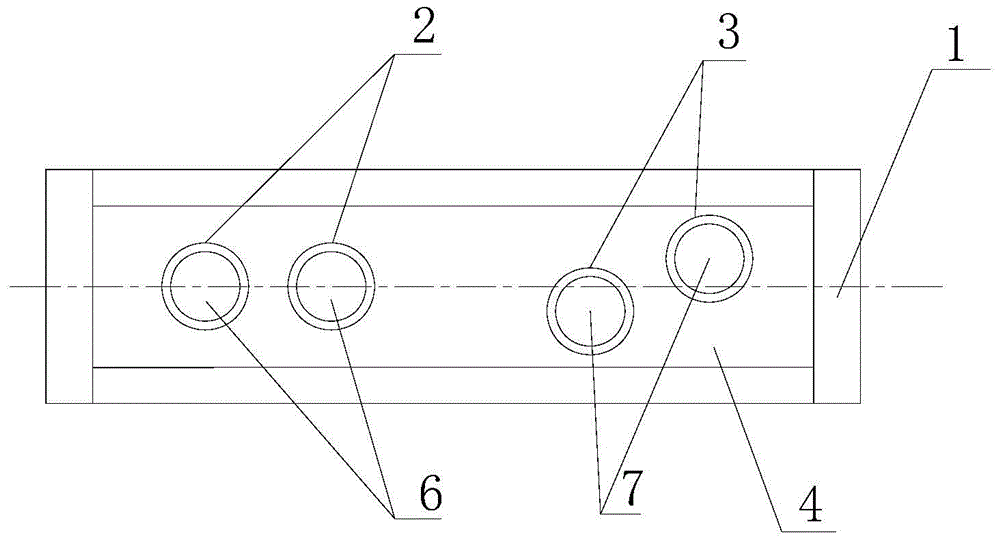

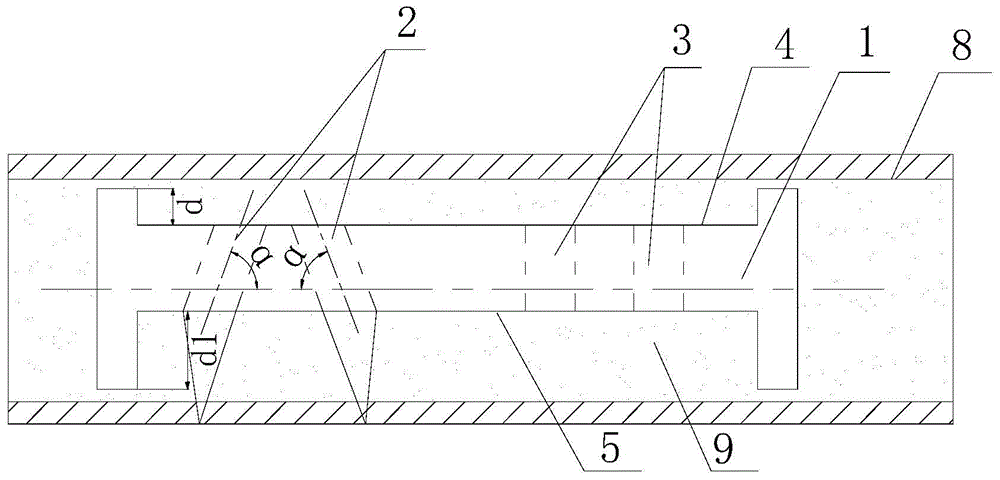

[0020] Such as figure 1 and 2 As shown, a nuclear power evaporator heat transfer tube inner hole flaw detection device is characterized in that it includes a base body 1 and a probe installed on the base body 1; the probe includes two flaw detection point focusing probes 6 and two line focusing probes 7. The seat body 1 is a cylinder with a diameter less than 12mm, wherein the first concave table surface 4 and the second concave table surface 5 are opened on the side of the cylinder, and the first concave table surface 4 and the second concave table surface 5 are Parallel, forming a structure with two ends as cylinders and two parallel concave tables in the middle, and four through holes are opened on the two parallel concave tables, which are respectively two holes for installing the flaw detection point focusing probe 6 One through hole 2 and two through holes two 3 for installing the line focusing probe 7, and the transmitting end of the probe is located on the second conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com