Apparatus for joining a carcass ply

A carcass ply and equipment technology, applied in tires, applications, household appliances, etc., can solve the problems of difficult to maintain precision, difficult production, complex structure, etc., and achieve the effect of simplifying the cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

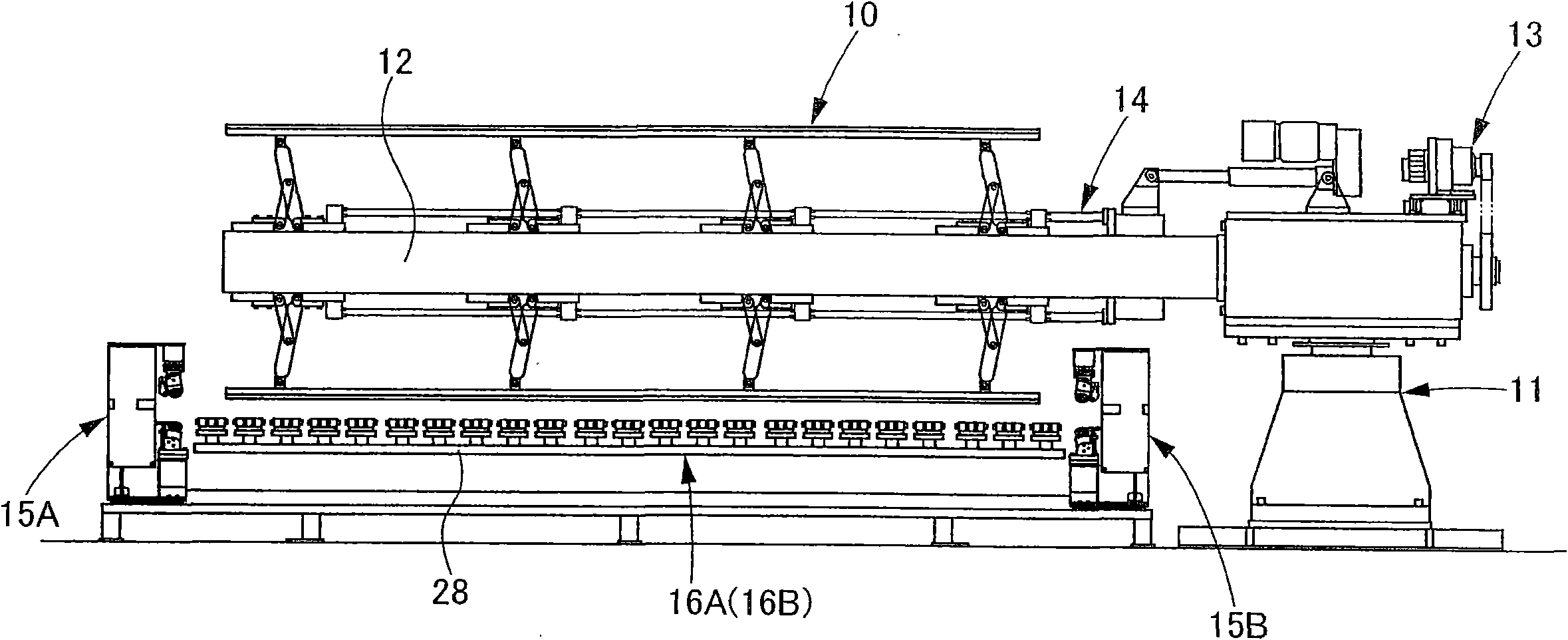

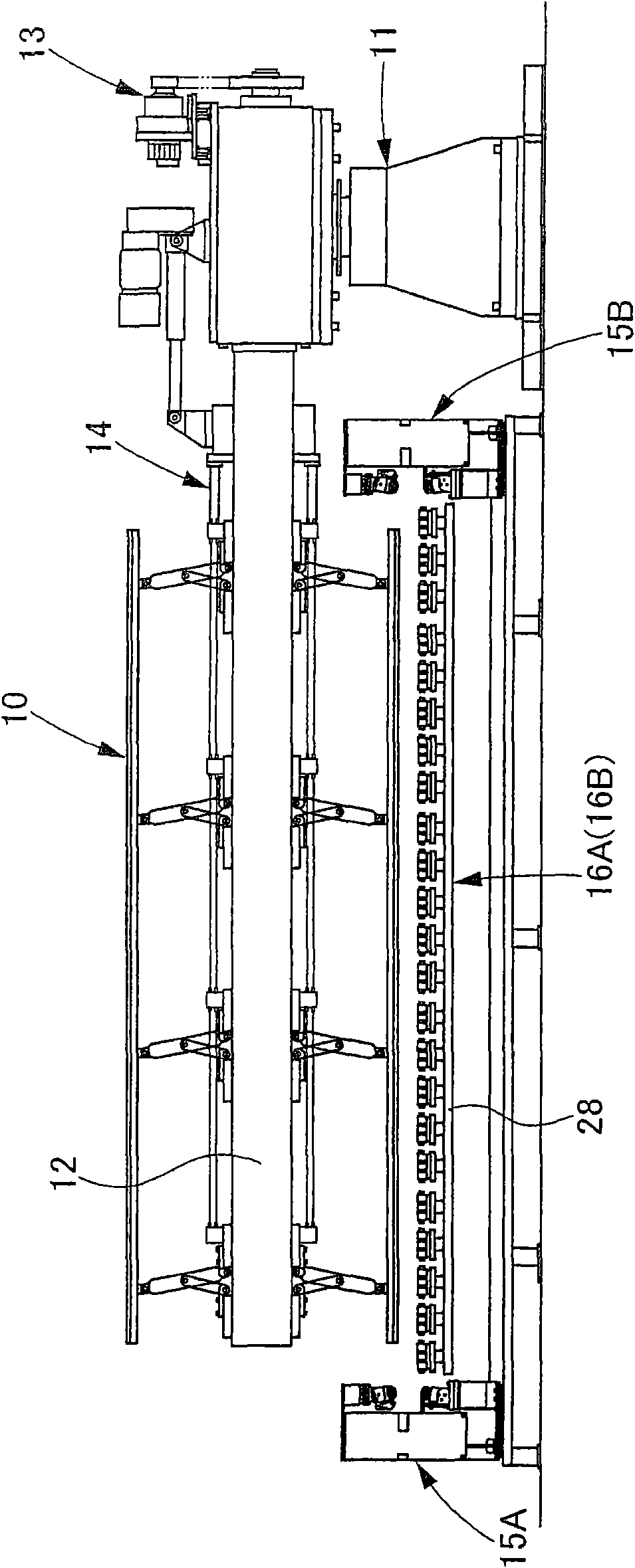

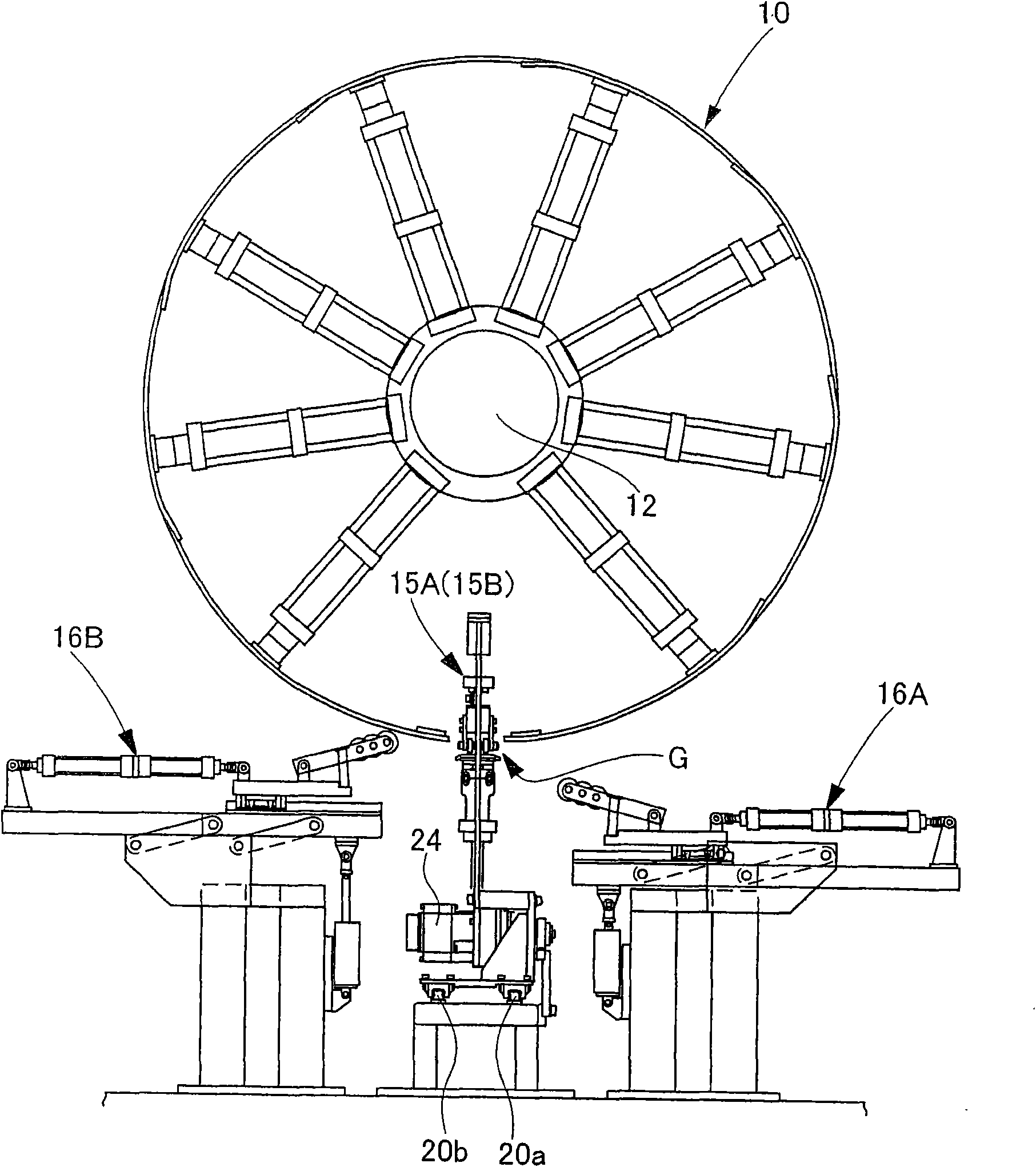

[0042] Fig. 1 is a front view showing an apparatus for joining carcass plies according to Embodiment 1 of the present invention. Figure 2 is a side view of an apparatus for joining carcass plies. Fig. 3 is a front view of a connection part. Fig. 4 is a side view of the connecting portion. Fig. 5 is a detailed side view of the alignment part. Fig. 6 is an explanatory view of the movement of the cylindrical barrel. Fig. 7 is another movement explanatory diagram of the cylindrical barrel. FIG. 8 is a detailed view of FIG. 7 . Fig. 9 is an explanatory diagram of the movement of the connecting portion. Fig. 10 is an explanatory diagram of movement of registration rollers. FIG. 11 is a detailed view of FIG. 10 . FIG. 12 is an explanatory diagram of movement of the alignment unit. Fig. 13 is an explanatory diagram of the movement of the connecting roller and the alignment roller. FIG. 14 is a detailed view of FIG. 13 . Fig. 15 is an explanatory diagram of movement of the al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com