Method and system for dynamically calibrating precision of heliostat of tower type solar thermal power generation system

A thermal power generation system, tower solar technology, applied in the direction of electrical testing/monitoring, use feedback control, etc., can solve the problem that the accuracy and reliability of the calibration results cannot be guaranteed, the sun's rays are reflected on the heat absorber, and the fixed Solve problems such as interference in the Sun Mirror calibration process, achieve the effects of improving efficiency and accuracy of calibration results, eliminating conflicts, and improving accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

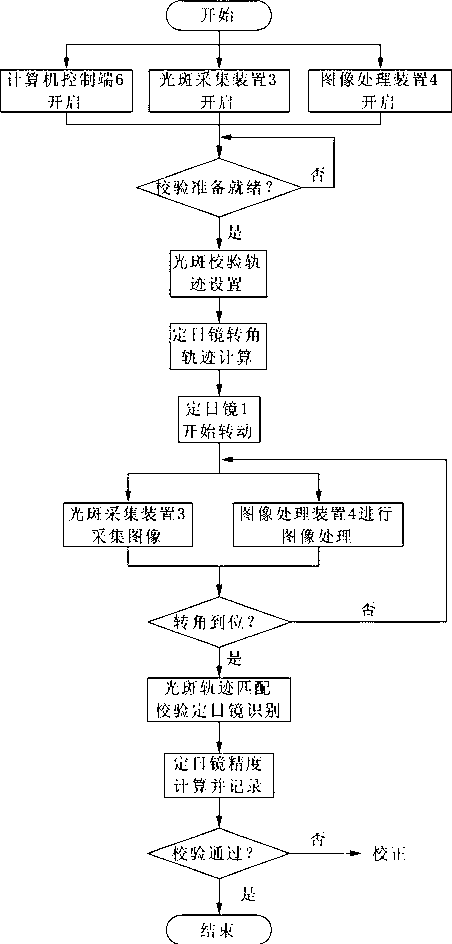

[0038] The present invention will be further explained in detail below in conjunction with the accompanying drawings.

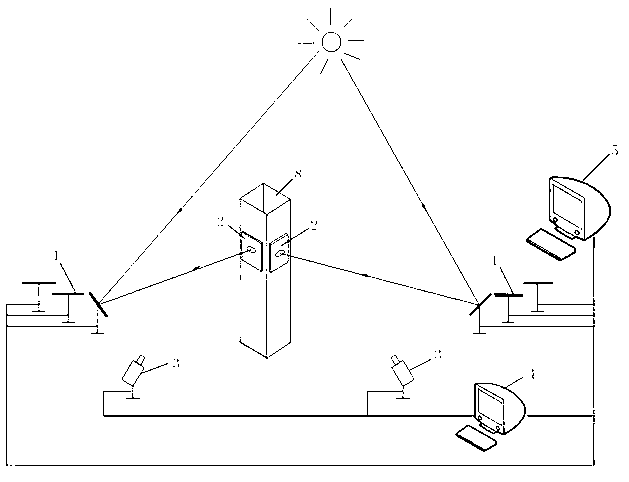

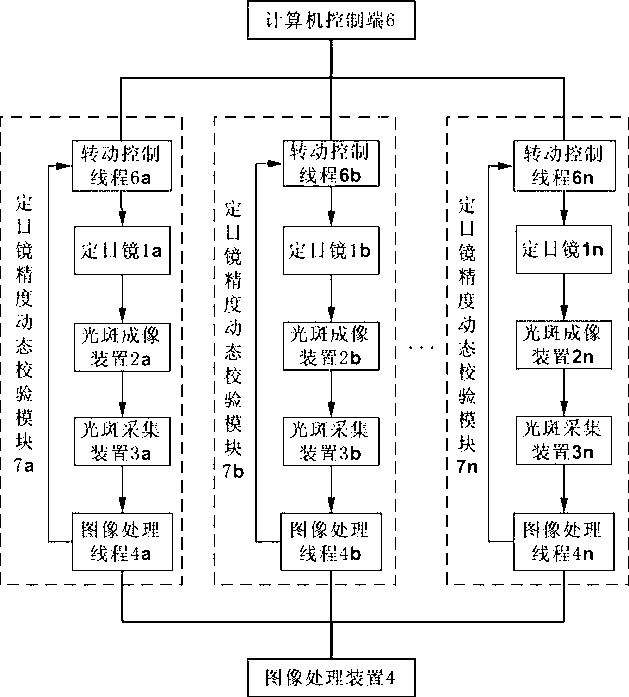

[0039] Such as figure 1 As shown, a heliostat accuracy dynamic calibration system for a tower solar thermal power generation system, including:

[0040] The heliostat 1 is used to track and reflect sunlight, and is the object to be calibrated in the heliostat precision calibration system;

[0041] The spot imaging device 2 is used to form a sun spot image, and is a carrier for realizing the spot verification track;

[0042] The spot collecting device 3 is used to collect the solar spot image on the spot imaging device 2, and transmit the image data to the image processing device 4 through the data transmission system;

[0043] The image processing device 4 is used to process the solar spot image collected by the spot acquisition device 3, wherein the solar spot image formed by the sun light reflected by the heliostat on the spot imaging device is collected by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com