Liquid feed distributor for lamella heat exchanger

A feed distributor and feed distribution pipe technology, applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problem of reducing the maintenance workload and difficulty of the distributor, and the distribution center distribution dead zone problems, to achieve the effect of simplifying maintenance difficulty and workload, simplifying disassembly and assembly procedures, and optimizing the uniformity of feed distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

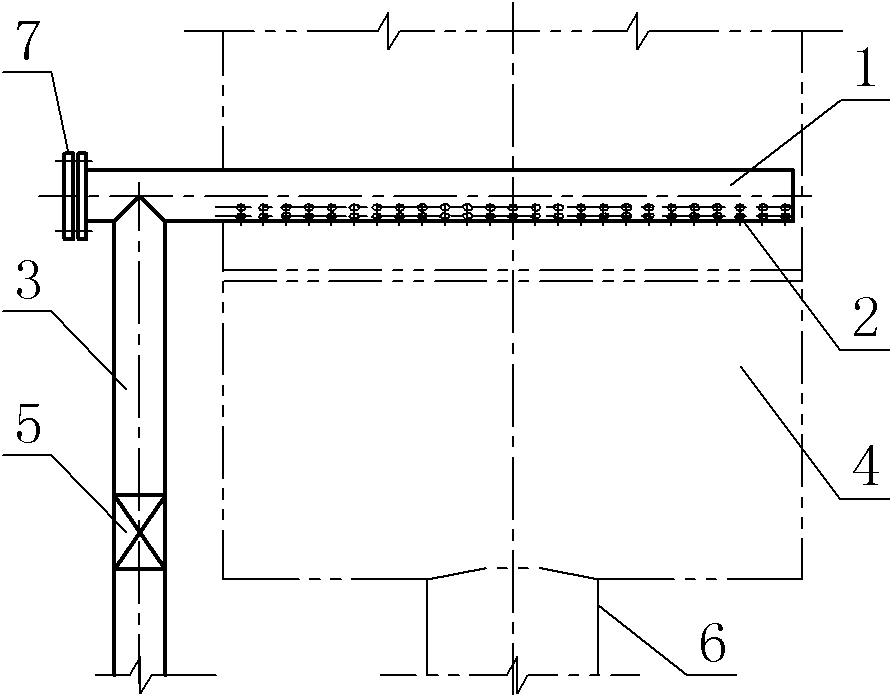

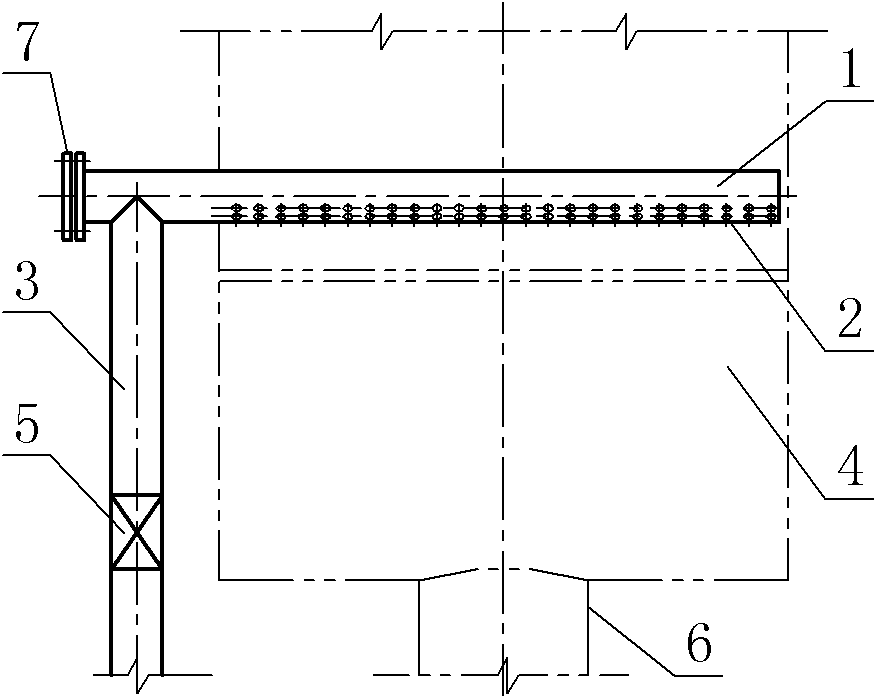

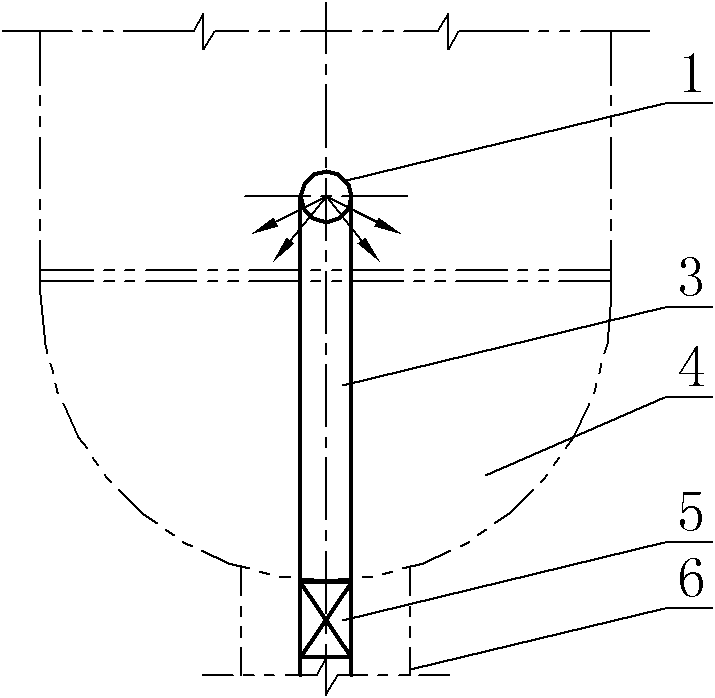

[0028] Specific embodiments of the present invention refer to accompanying drawings. Numbers in the picture: 1. Feed distribution pipe 2. Distribution hole 3. Feed access pipe 4. Plate bundle 5. Expansion joint 6. Gas pipeline 7. Feed distribution pipe end flange 8. Feed access Pipe connection flange 9. The connection flange between the feed distribution pipe and the plate bundle.

[0029] The liquid feed distributor is composed of a feed distribution pipe 1 and a feed access pipe 3 . The liquid feed is connected from the external connection pipe, flows through the expansion joint 5, the feed inlet pipe 3, and the feed distribution pipe 1 in sequence, and the distribution of the feed is realized by the distribution hole 2 on the feed distribution pipe 1. The feed distribution pipe 1 and the feed inlet pipe 3 are outside the gas pipeline 6 .

[0030] Refer to Figure 1 for the structure of the fixed connection between the feed distribution pipe, the plate bundle and the feed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com