A connection structure that is easy to realize rapid disassembly and assembly underwater after irradiation and its assembly method

A connecting structure and fast technology, applied in the direction of connecting components, screws, threaded fasteners, etc., can solve the problems of increasing the difficulty of underwater disassembly, transfer into the spent fuel pool, damage to screws, etc., and achieve a simple structure and simplified disassembly and assembly. Program, the effect of easy disassembly and assembly under water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

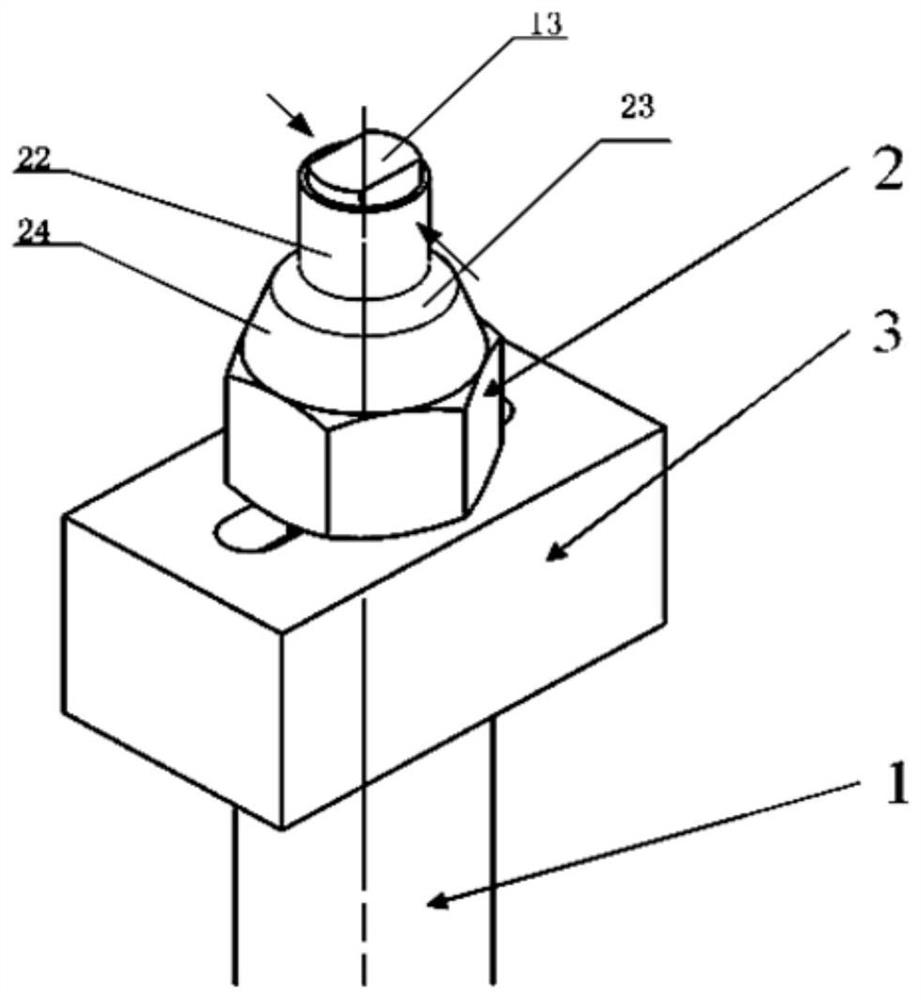

[0042] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown:

[0043] A connection structure that is easy to quickly disassemble and assemble underwater after irradiation,

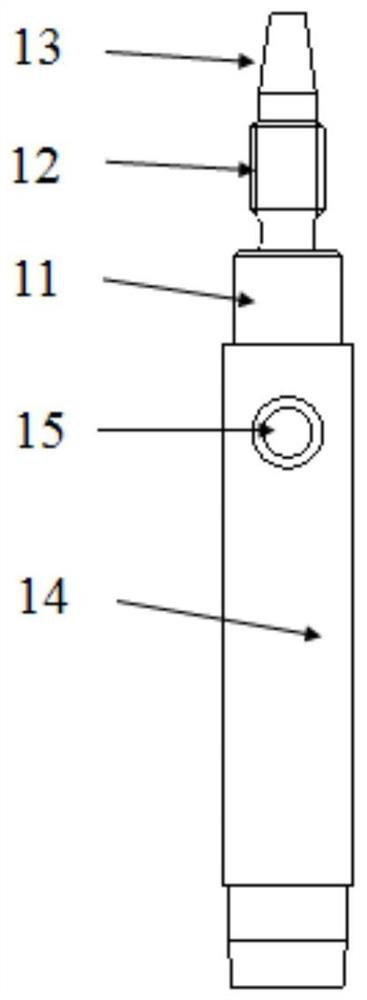

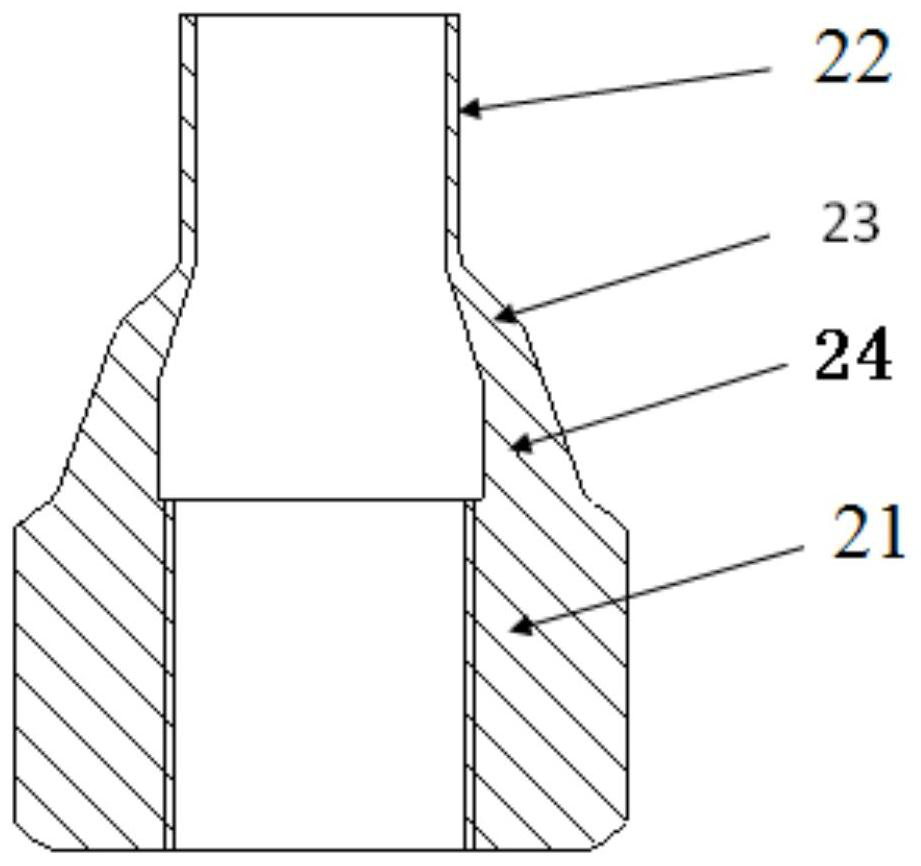

[0044] It includes a structural main body 3 with an anti-rotation mounting hole 31, and an anti-rotation screw 1 inserted into the anti-rotation mounting hole 31. The circumferential side wall of the anti-rotation screw 1 protrudes to form an anti-rotation boss 11. The anti-rotation The anti-rotation boss portion 11 is located in the anti-rotation mounting hole 31 and matches the shape of the anti-rotation mounting hole 31. The circumferential side wall of the anti-rotation screw rod 1 is provided with a thread to form a threaded portion 12, and the threaded portion 12 is located on the anti-rotation boss portion. 11, above the threaded part 12, there is a section of top 13, which also includes a skirt nut 2. The skirt nut 2 includes a nut body 21 screwed on the threaded part 12, and the upper end...

Embodiment 2

[0050] On the basis of above-mentioned embodiment 1, the present invention also faces to the design problem of top 13 and the cooperating design of top 13 and skirt, and the design of its top 13 and skirt follows a design purpose, promptly prevents that skirt is relative to top 13 takes place circumferential rotation motion. Regarding this design purpose, the present invention provides two preferred solutions, one is to press and fit, such as Figure 5 shown, one is an embedded design such as Figure 6 shown.

[0051] Such as Figure 5 As shown, extrusion fit method: the top 13 includes an equal-diameter section adjacent to the threaded portion 12 and above the threaded portion 12, and also includes an upwardly reduced diameter-reducing section adjacent to the equal-diameter section and above the equal-diameter section , the special-shaped structure is matched and connected with the diameter-reducing section, and the special-shaped structure is deformed into a wedge-shaped ...

Embodiment 3

[0060] An assembly method for a connection structure that is easy to realize quick disassembly and assembly underwater after irradiation, including assembly operation and disassembly operation,

[0061] Assembly operation:

[0062] S1. Insert the anti-rotation screw 1 into the anti-rotation mounting hole 31 of the structural body 3 by using a mechanical clamp, so that the anti-rotation boss 11 is located in the anti-rotation mounting hole 31;

[0063] S2. Screw the nut body 21 of the skirt nut 2 onto the threaded part 12 by using a mechanical fixture;

[0064] S3. Extruding the skirt structure with a mechanical clamp, deforming the skirt structure and extruding the skirt structure on the outer surface of the special-shaped structure at least in a circumferential direction;

[0065] Disassembly operation:

[0066] A. The nut body 21 is reversely rotated by a mechanical fixture, and the nut body 21 drives the skirt structure to rotate, and the deformed part of the skirt struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com