A power installation structure for an axis-pull electric aircraft

An installation structure and aircraft technology, applied in the field of aviation electromechanical, can solve the problems of motor falling off, no consideration of heat dissipation, vibration reduction, anti-collision, inconvenient disassembly and assembly of motors, etc., to reduce impact, simplify motor disassembly procedures, and eliminate safety issues. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

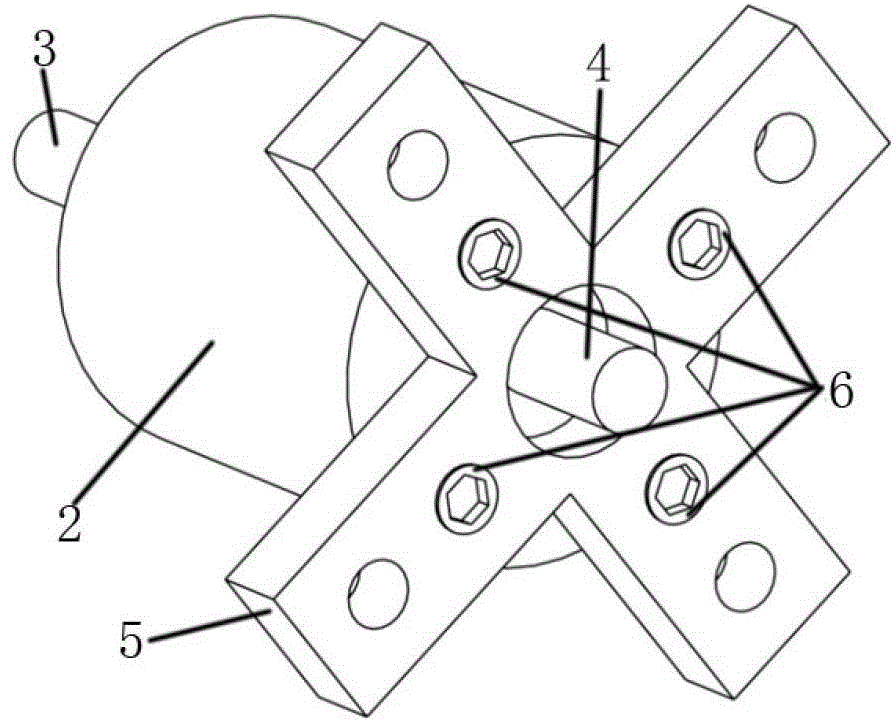

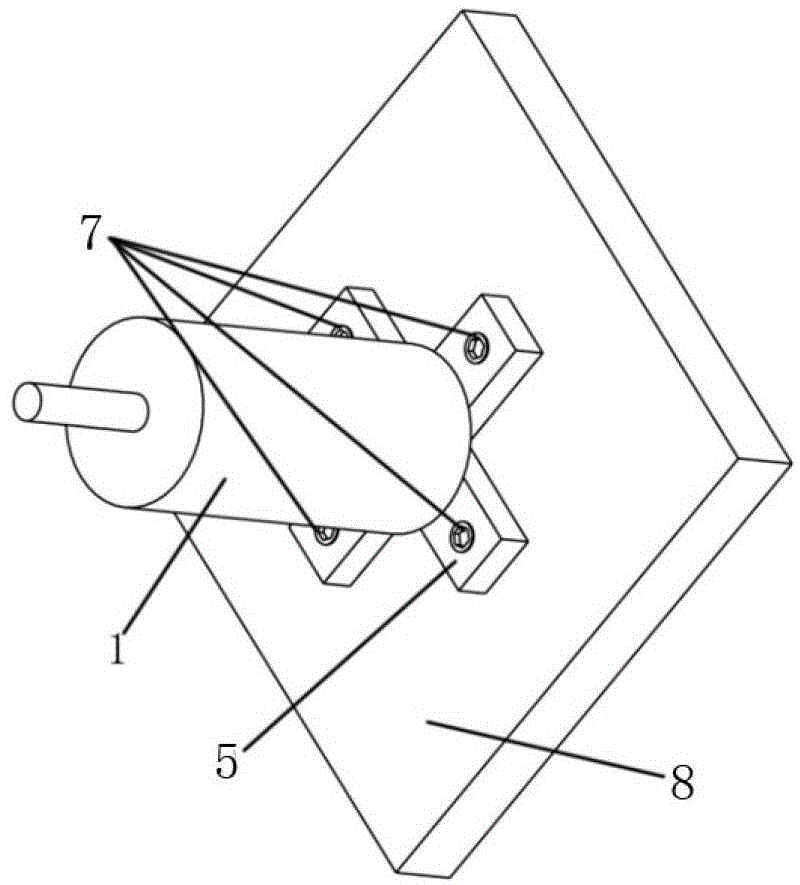

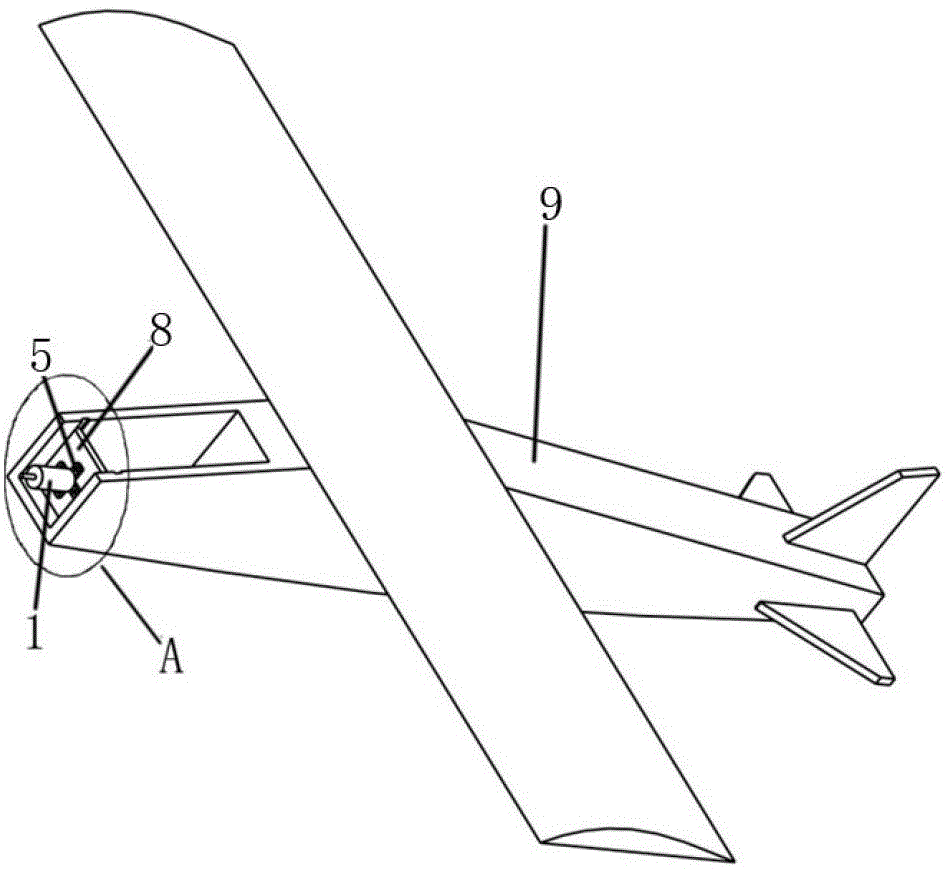

[0030] The existing structure of the power installation of the electric aircraft pulled forward by the axis: such as figure 1 As shown, the motor 1 and the motor bracket 5 are connected by bolt I6; figure 2 As shown, the motor bracket 5 is then connected to the plate 8 through bolt II7; image 3 As shown, the motor 1, the motor bracket 5, the plate 8 and the fuselage 9 are assembled and connected; Figure 4 yes image 3 In the enlarged view of area A, the plate 8 is buckled or bonded to the fuselage 9 . The existing structure has the hidden danger of the motor falling off due to the loosening of the bolts, the disassembly and assembly of the motor is inconvenient, and problems such as heat dissipation, vibration reduction, and anti-collision are not considered.

[0031] In the first solution of the present invention, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com