Spool material retractable feeder

A technology of I-shaped wheel, retractable material, applied in the field of welding wire production equipment, can solve the problems of unreliable top tightening, I-shaped wheel flywheel accident, and the inability of the top tightening shaft to move, etc., to achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

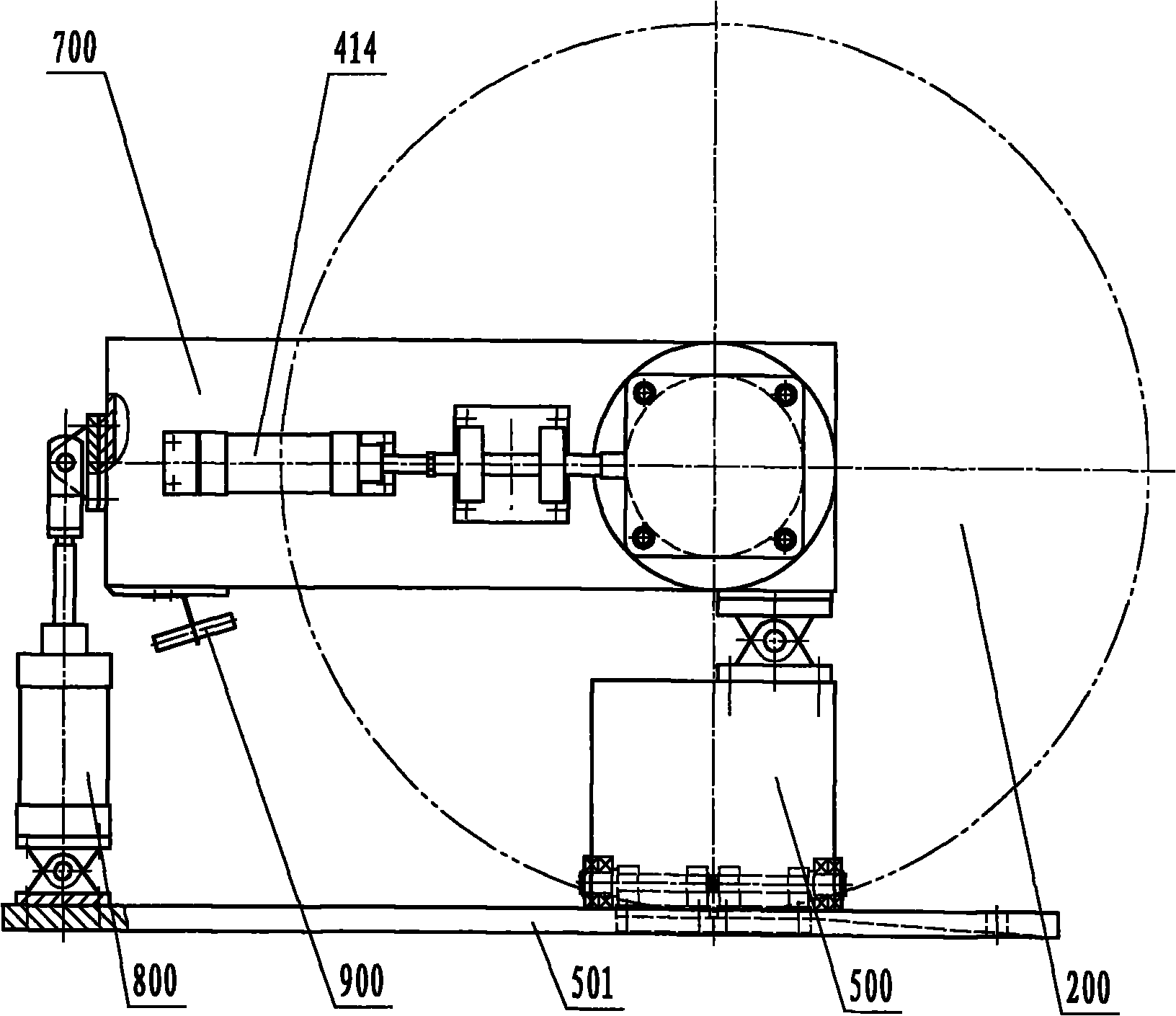

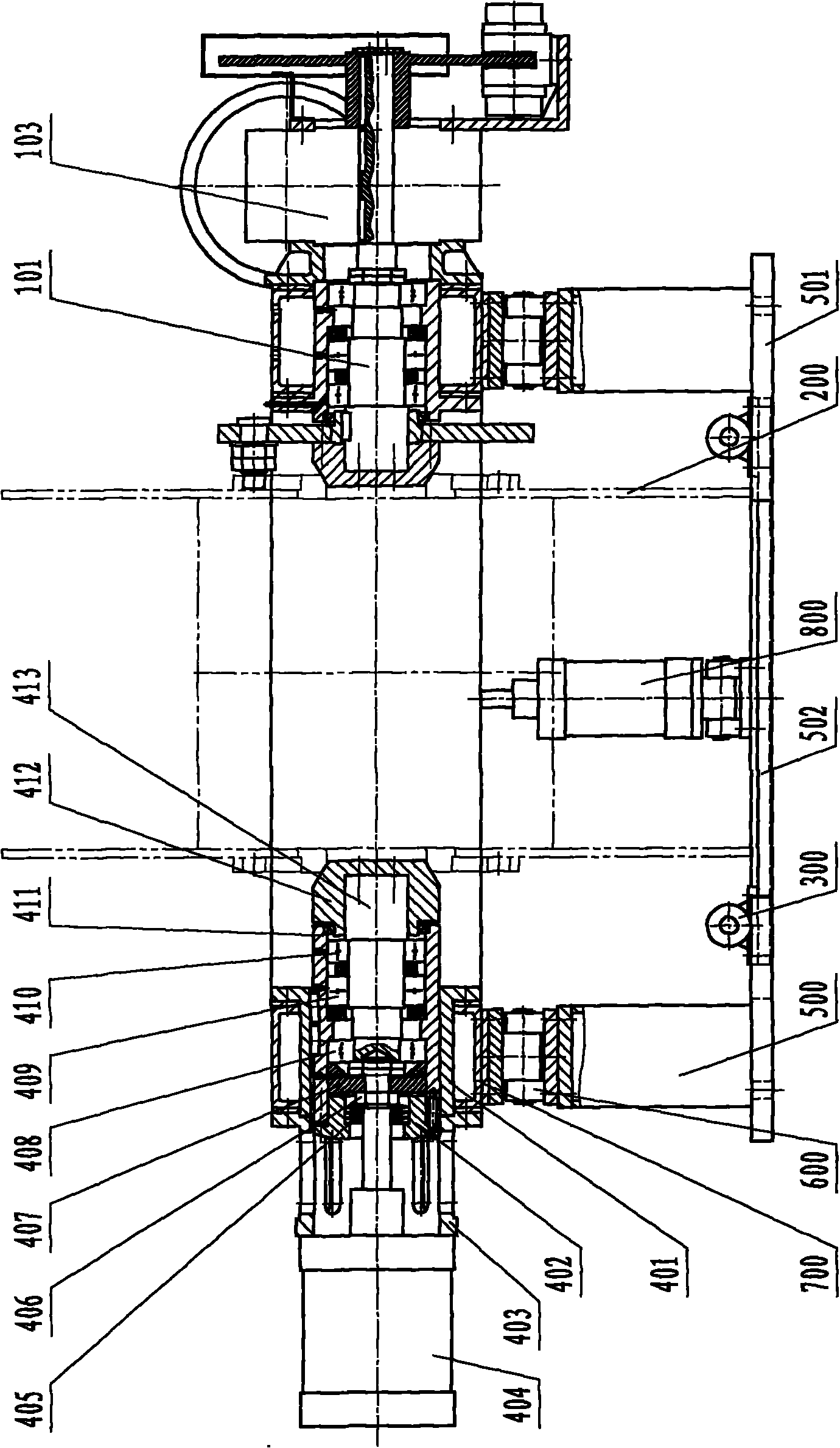

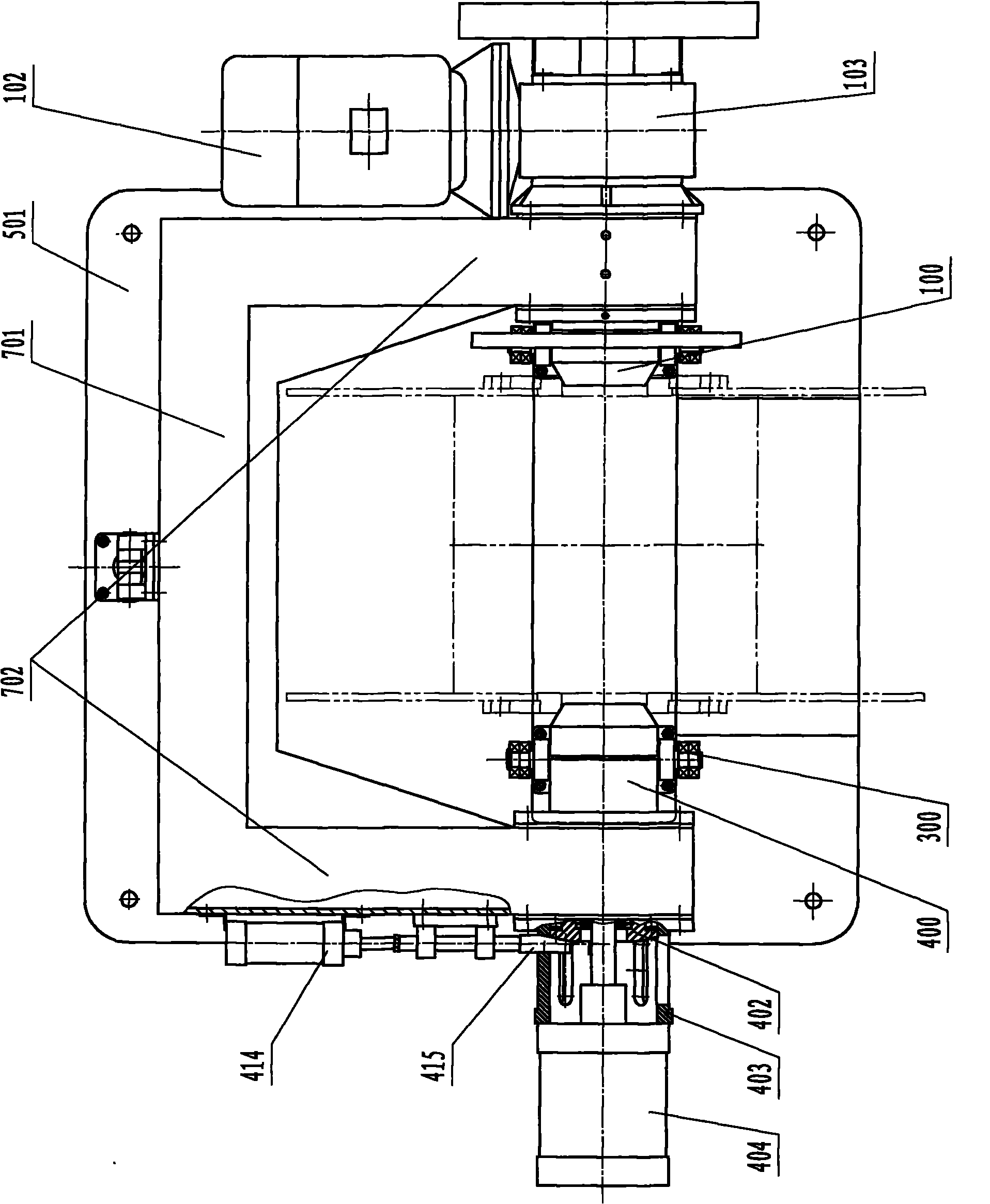

[0031] see Figure 1 ~ Figure 3 , a kind of I-shaped wheel retracting and unwinding machine of the present invention includes an electric control system (not shown in the figure), a bracket 500, and a driving shafting 100 and a top tightening shafting 400 installed on the bracket 500. The driving shafting 100 includes The top of the drive shaft 101 and the bracket 500 is connected with a door frame-shaped support arm 700 through a hinge 600, the front end of the support arm 700 is set as an opening, and the rear end of the support arm 700 is provided with a closed horizontal bar 701; the drive shaft system 100 and the jacking shaft system 400 are respectively installed on the two door frames 702 of the support arm 700, and the lifting mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com