Method for deacidifying and refining high-acid value fish oil by using enzyme method

A high acid value, fish oil technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of high energy consumption, large lipase consumption, high comprehensive cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

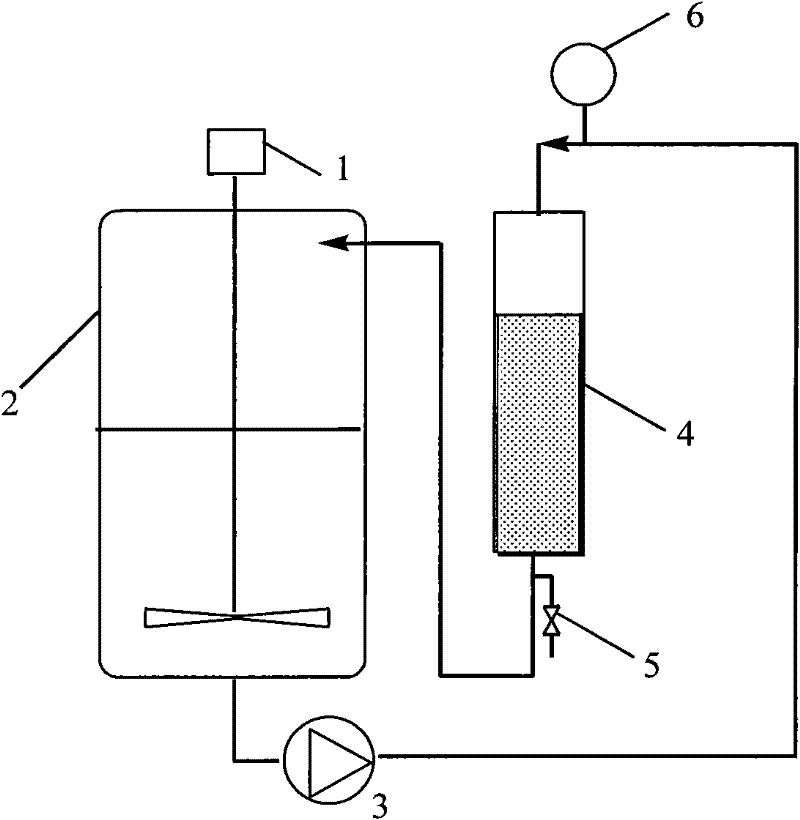

Embodiment 1

[0031] Such as figure 1 As shown, the acid value is that 5.0kg of tuna oil of 36.3mgKOH / g and dehydrated alcohol 90g join in the stainless steel material tank 2 (the stirrer in the material tank 2 is driven by stirring motor 1) with jacket, the packed bed enzyme reaction 50g immobilized enzyme novozyme 435 is loaded into device 4 (the inlet of packed bed enzyme reactor is provided with pressure gauge 6), and the mixture of high acid value tuna oil and dehydrated alcohol flows through enzyme reactor through gear material pump 3, and material The flow rate of the pump is 0.1L / min, so that the residence time of the reactant through the immobilized lipase is 60 seconds, and the reaction temperature is 60°C. During the reaction, samples are continuously taken through the sampling port 5 located at the outlet of the packed bed enzyme reactor. After removing ethanol by rotary film evaporator, analyze the changes of acid value and other components. After 6 hours, the acid value of oil...

Embodiment 2

[0033] Reactor such as figure 1 , 5.0kg of tuna oil with an acid value of 36.3mgKOH / g and 180g of absolute ethanol were added in a stainless steel material tank with a jacket, and 500g of immobilized enzyme novozyme 435, high acid value tuna oil and The mixture of absolute ethanol is transported through the enzyme reactor through the gear pump, the flow rate of the pump is 1L / min, the residence time of the reactant through the immobilized lipase is 60 seconds, the reaction temperature is 50°C, and samples are taken continuously during the reaction. After the sample is removed from ethanol by a rotary film evaporator, analyze the changes in acid value and other components. After 1 hour of enzyme reaction, the acid value of the oil becomes 4.7mgKOH / g, stop the reaction, recover ethanol, and take 1kg of oil after recovery of ethanol Add 38mL of NaOH solution and 150mL of distilled water with a mass concentration of 10%, stir while adding, a large amount of soap is produced, after...

Embodiment 3

[0035] Reactor such as figure 1 As shown, 5.0kg of tuna oil with an acid value of 36.3mgKOH / g and 120g of absolute ethanol were added to a stainless steel material tank with a jacket, and 250g of immobilized enzyme novozyme 435 was loaded into the packed bed enzyme reactor, and high acid value tuna The mixture of oil and absolute ethanol is transported through the enzyme reactor by a gear pump, the flow rate of the pump is 1L / min, the residence time of the reactant after passing through the immobilized lipase is 30 seconds, the reaction temperature is 40°C, and samples are taken continuously during the reaction , the sample was removed from ethanol by a rotary film evaporator to analyze the changes in acid value and other components. After 1 hour, the acid value of the oil became 6.2mgKOH / g, stop the reaction, recover ethanol, and add 1kg of oil after recovering ethanol Mass concentration is 10% NaOH solution 50mL and 150mL distilled water, stir while adding, a large amount of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com