Method for transforming fatty acid ethyl ester into glyceride

A technology of fatty acid ethyl ester and glyceride, which is applied in the field of oil processing, can solve the problems of low reaction speed and conversion rate, and limit industrial application, and achieve the effects of improving reaction efficiency, solving encapsulation, and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

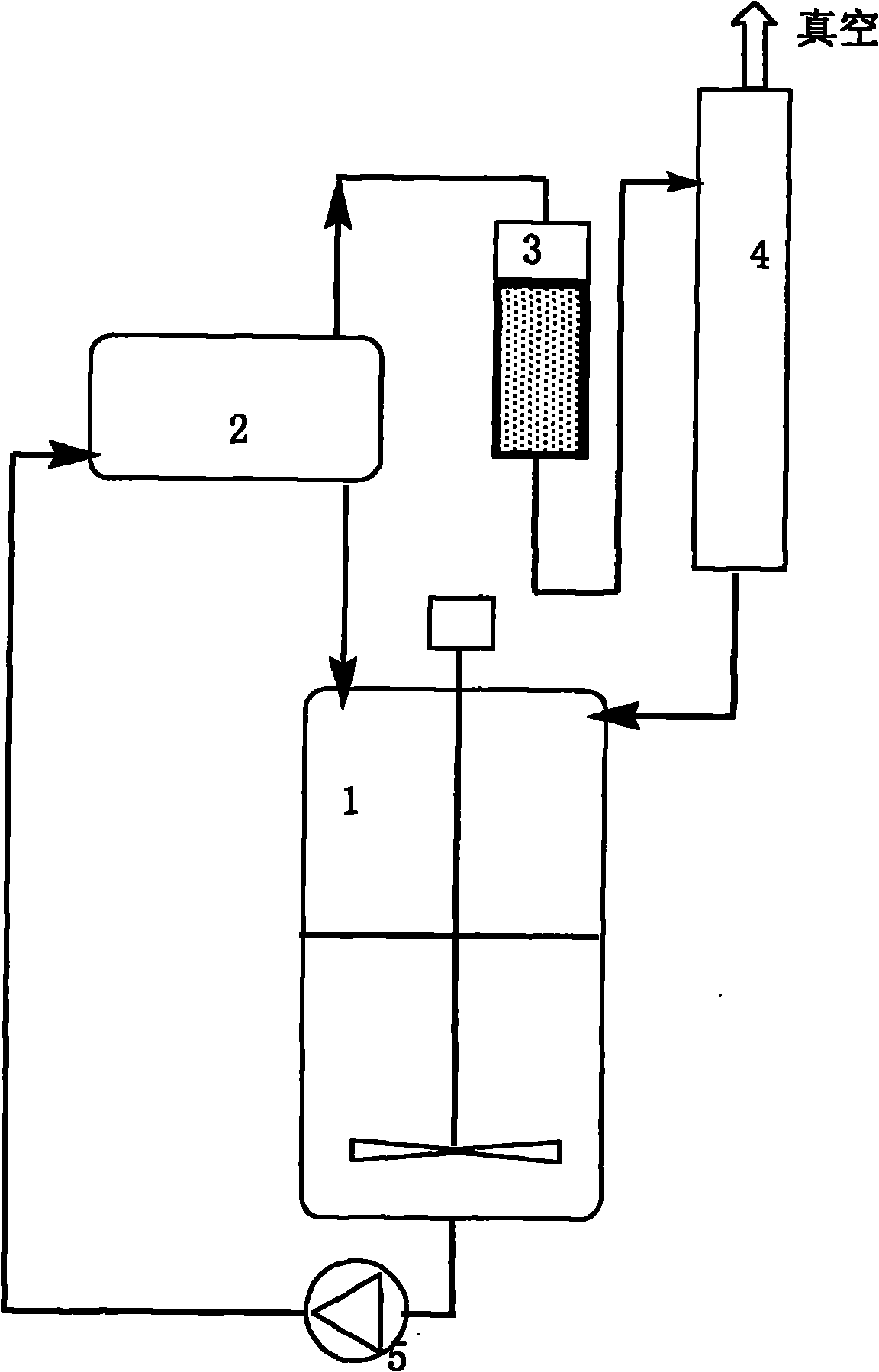

[0031] Reactor such as figure 1 shown. 1 ton of fatty acid ethyl ester derived from fish oil and 90 kg of glycerin with EPA content of 30% and DHA content of 20% are added to the material tank 1, and are pumped to flow through the fiber bed phase separator 2, enzyme reactor 3 and packed tower 4. The flow rate of pump 5 is 15m 3 / hr, the consumption of enzyme is 30kg (Novozym 435, Novozymes company product), reaction temperature is 60 ℃, reaction system pressure is 400~600pa, stop reaction after 36 hours, reaction product result is shown in Table 1. The reaction product is distilled to remove fatty acid ethyl ester to obtain glyceride-type products.

Embodiment 2

[0033] Replace with the new raw material of the same formula as in Example 1, adopt the reclaimed enzyme preparation of Example 1 to react, and repeat the operation of Example 1.

Embodiment 3

[0035]Replace with the new raw material of same formula as embodiment 1, adopt embodiment 2 to reclaim the enzyme preparation and carry out reaction, repeat embodiment 1 operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com