Harmomegathus difference-resistant plate fixing device for sheet manufactured by gantry electrofacing

A fixed device and gantry-type technology, which is applied in the fields of printed circuit manufacturing, electrical components, electrolysis process, etc., can solve the problems of large expansion and contraction difference, thin plate angular deformation, high cost of horizontal electroplating line, etc., and achieve simple structure and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

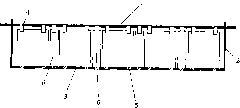

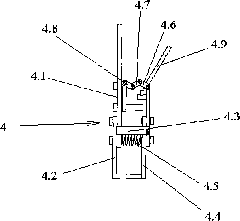

[0013] As shown in the figure, the present invention mainly consists of hanger top plate 1, hanger side plate 2, hanger bottom plate 3, bottom plate slot 3.1, upper chuck 4, installation side plate 4.1, chuck inner plate 4.2, installation horizontal plate 4.3 , Chuck outer plate 4.4, back-moving spring 4.5, the first connecting plate 4.6, the second connecting plate 4.7, the third connecting plate 4.8, operating panel 4.9, jacking bolt 5 and connecting plate 6 and other components.

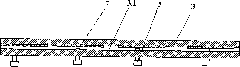

[0014] The gantry-type electroplating plate fixing device for preventing expansion and shrinkage differences of thin plates includes hanger top plate 1, hanger side plate 2, hanger bottom plate 3, upper chuck 4, jacking bolts 5 and connecting plate 6, hanger bottom plate The two ends of 3 are fixedly provided with the hanger side plate 2, the top of the hanger side plate 2 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com