Method and equipment for automatically cooking silkworm cocoons

A cocoon cooking and automatic technology, applied in silk fiber production, textile and papermaking, mechanical processing, etc., can solve problems such as affecting product quality, affecting production efficiency, increasing the number of operators, etc. The effect of improving the quality index and level of cocoon and scientific management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

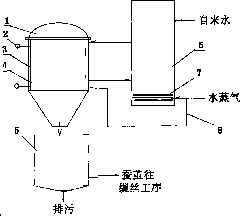

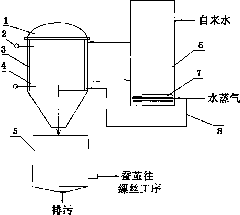

Image

Examples

Embodiment 1

[0037]The mulberry cocoon cooking process using the equipment of the present invention (XJ-08 intelligent silkworm automatic cocoon cooking machine): the first step, turn on the power, input the entire process program for cocoon cooking, press the touch screen, operate the hydraulic system, and open the cocoon processing tank The top cover 1 of 4, the operator pours in an appropriate amount of mulberry cocoon raw materials, closes the top cover 1, water is fed into the water supply tank 6, the water level sensor 2 adjusts the water level to 70% of the height of the tank body, and steam enters the silkworm cocoon treatment tank 4 through the steam delivery pipe 8 , adjust the vacuum infiltration temperature to 25°C, and carry out the soaking process; the second step is to boil the cocoon, and under the induction of the temperature sensor 2, the temperature of the boiled cocoon is in the range of 45-55°C (10°C lower than the conventional process); the third step , Steam cocoons. ...

Embodiment 2

[0039] The mulberry cocoon cooking process using the equipment of the present invention (XJ-08B intelligent silkworm automatic cocoon cooking machine): the first step, turn on the power, input the entire process program for cocoon cooking, press the touch screen, operate the hydraulic system, and open the cocoon processing tank The top cover 1 of 4, the operator pours in an appropriate amount of mulberry cocoon raw materials, closes the top cover 1, water replenishment tank 6 enters, the water level sensor 2 adjusts the water level to 60% of the height of the tank body, and steam enters the silkworm cocoon treatment tank 4 through the steam delivery pipe 8 , adjust the vacuum infiltration temperature to 20°C, and carry out the soaking process; the second step is to boil the cocoon, and under the induction of the temperature sensor 2, the temperature of the boiled cocoon is in the range of 45-55°C (10°C lower than the conventional process); the third step , Steam cocoons. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com