On-line monitoring and real-time display system of material transformation in the process of coal clean combustion

A coal and clean technology, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve problems such as lack of real-time monitoring, and achieve the effect of strengthening scientific management and improving emission reduction capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

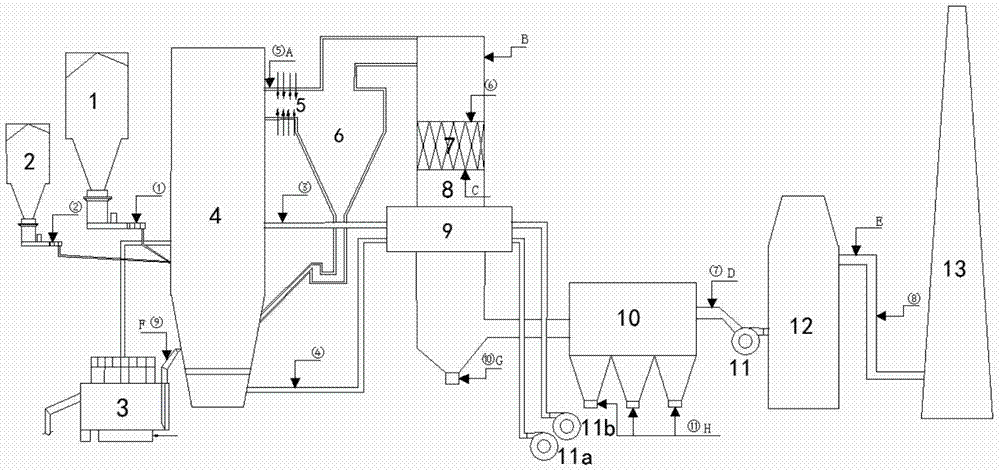

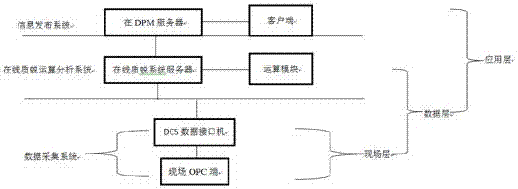

[0027] Such as figure 1 As shown, in this embodiment, the online monitoring and real-time display system for material degradation during the clean coal combustion process includes a data acquisition system, an online quality analysis system, and an information release system; The system connection forms the data layer, and the data layer is connected with the information release system to form the application layer; the DCS data interface machine and the firewall in the data acquisition system are all connected to the data interface of the original on-site OPC server for collecting the data of the OPC server, It is also connected with the online quality calculation and analysis system, and transmits the collected data from the OPC server to the online quality server. The server uses the network to present the calculation results in the form of system overview, data bar graph, historical / real-time trend curve, group query, alarm for pollutant discharge exceeding the standard, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com