Method for computing accurate value of carbon equivalent of cast iron and application of method

A calculation method and technology of carbon equivalent, applied in the field of cast iron alloys, can solve the problems of not considering the content and function of trace elements, the inability to accurately control carbon equivalent, and the increase of shrinkage and porosity defects in castings, so as to eliminate genetic influences, improve internal quality, The effect of reducing internal shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

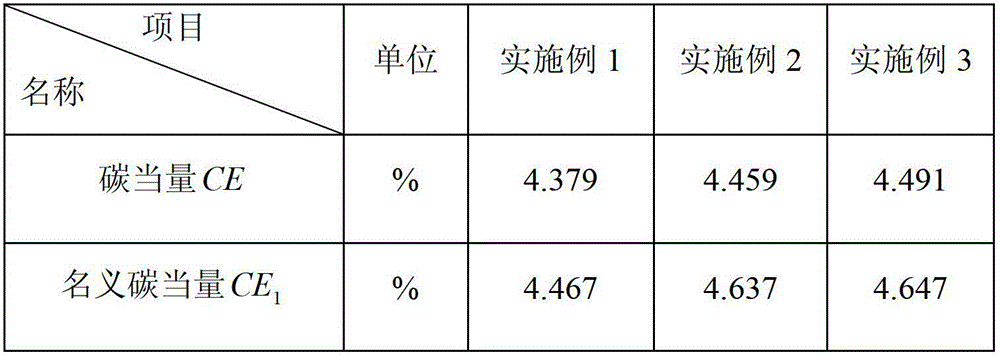

Embodiment 1~3

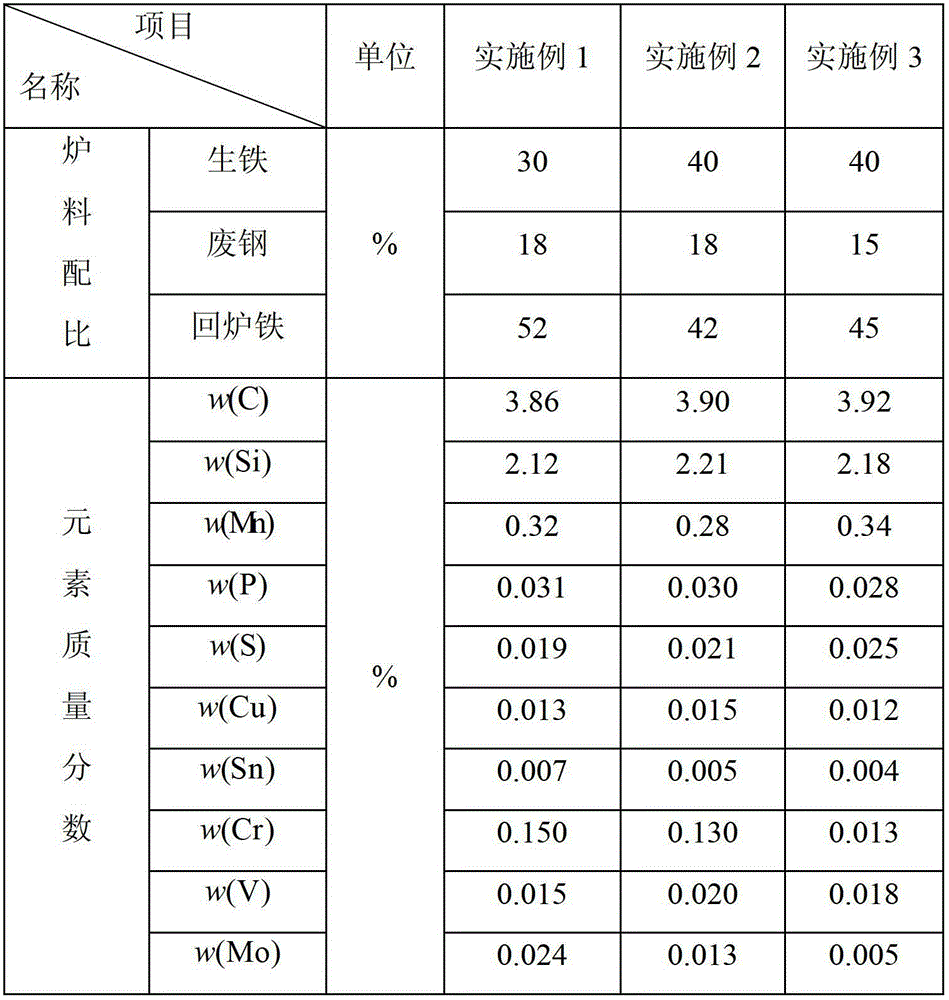

[0016] Table 2 embodiment 1~3 spectrometer detection result

[0017]

Embodiment 1

[0019] In the present embodiment, its method is as follows:

[0020] a) According to the furnace charge ratio: 30% pig iron, 18% scrap steel, 52% returned iron, the molten iron is smelted by an induction furnace, and the mass fraction of carbon in the molten iron is detected by a spectrometer w(C), and the mass fraction of silicon w(Si ), the mass fraction w(M) of each element except iron in molten iron i , w(M) involved in this example i Including w(C), w(Si), w(Mn), w(P), w(S), w(Cu), w(Sn), w(Cr), w(V) and w(Mo) , the test results are shown in Table 2;

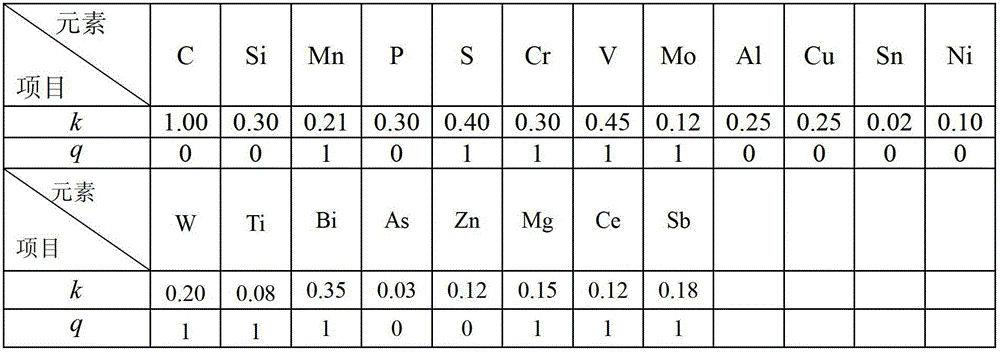

[0021] b) Establish carbon equivalent formula Among them, q is the graphitization tendency index of elements, which is 0 for elements that promote graphitization, and 1 for elements that hinder graphitization; n is the number of elements, and k is the graphitization degree coefficient of elements in molten iron; q, n, The k value is shown in Table 1, and the q, n, k values and the mass fraction w(M) of each element m...

Embodiment 2

[0028] In the present embodiment, its method is as follows:

[0029] a) According to the furnace charge ratio: 40% pig iron, 18% scrap steel, 42% returned iron, the molten iron is smelted by an induction furnace, and the mass fraction of carbon in the molten iron is detected by a spectrometer w(C), and the mass fraction of silicon w(Si ), the mass fraction w(M) of each element except iron in molten iron i , w(M) involved in this example i Same as embodiment 1, the graphitization degree coefficient k of elements in the molten iron;

[0030] b) Establish carbon equivalent formula Among them, q is the graphitization tendency index of elements, which is 0 for elements that promote graphitization, and 1 for elements that hinder graphitization; n is the number of elements, and k is the graphitization degree coefficient of elements in molten iron; q, n, The k value is shown in Table 1, and the q, n, k values and the mass fraction w(M) of each element measured in step a) i Subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com