High-speed railway track accurate adjusting device

A high-speed railway and track technology, which is applied in the directions of track, track laying, track maintenance, etc., can solve the problems of error-prone software design and actual use, complicated Boger fine-tuning system, difficult manufacturing and handling, etc. The effect of less error sources and simple tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

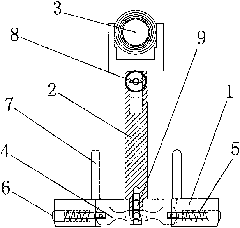

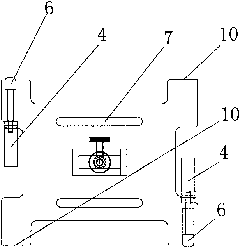

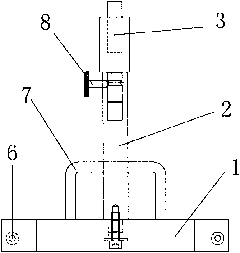

[0025] The invention provides a high-speed railway track fine adjustment device, which is composed of a base 1 , a column 2 and a prism 3 .

[0026] Such as figure 1 , image 3 As shown: one end of the column 2 is fixed to the base 1 through the bolt 9, and is perpendicular to the bottom surface of the base 1; the other end is connected to the prism 3, and the prism 3 is fixed to the column 2 through the screw 8. The reflection center of the prism 3 and the geometric center of the base 1 are located on the axis of the column 2, and the axis is perpendicular to the bottom surface of the base 1, and the distance from the reflection center of the prism 3 to the bottom surface of the base 1 is equal to the height of the rail. The interface between the column 2 and the prism 3 can be flexibly selected according to the prism 3 .

[0027] Such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com