Method for controlling a motorised roller shutter installation with guidable slats

An adjustment method and blinds technology, applied in the direction of blinds/movable grilles, windows/doors, door/window protection devices, etc., can solve problems such as loss of orientation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

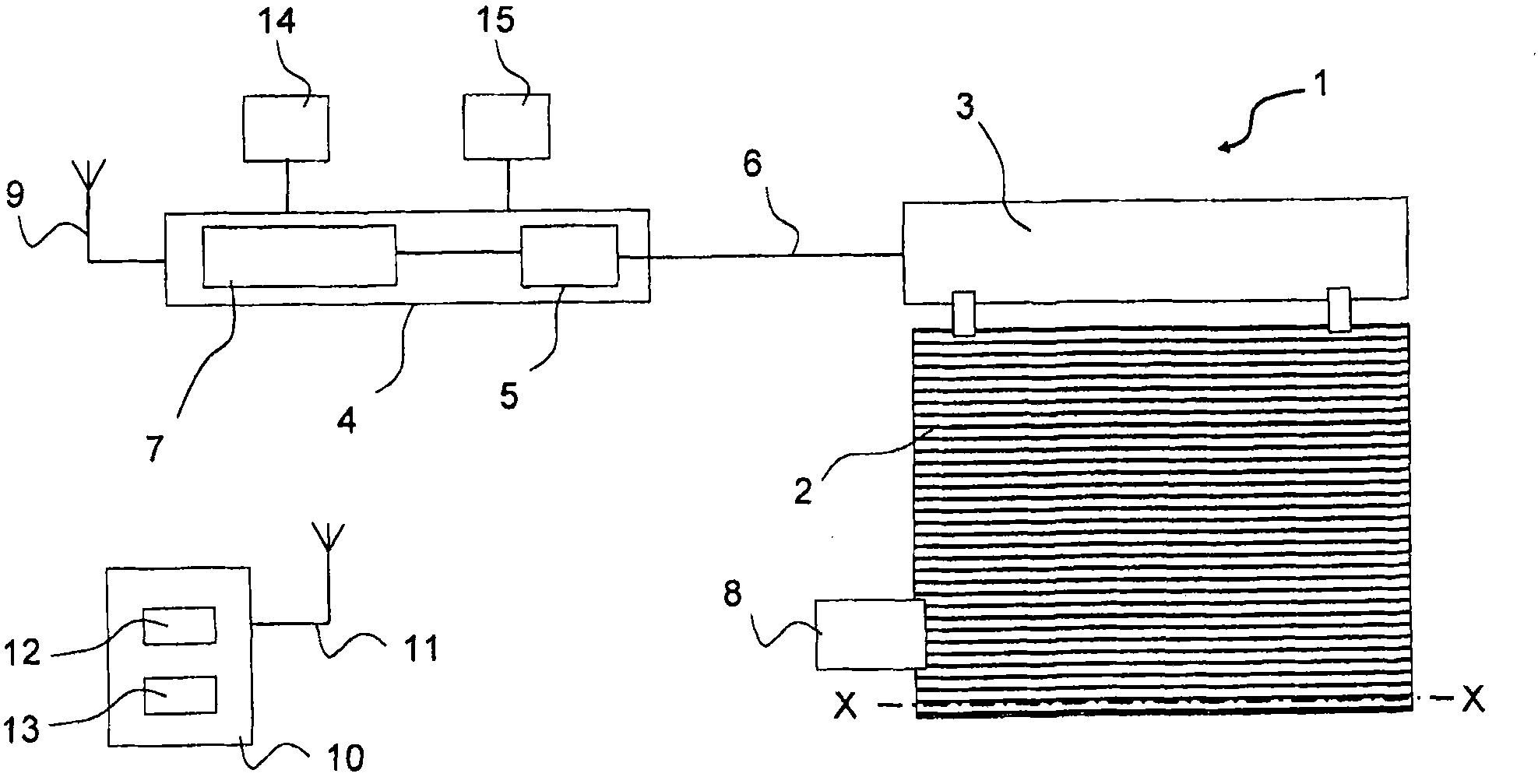

[0044] figure 1 A movable shutter device 1 fitted in a building is described, comprising a shutter 2 to be rolled up on a drum 3 in which is mounted a tubular actuator 4 (for simplicity, the actuator is shown exist figure 1 outside the reel). The actuator comprises a motor 5 and mechanical elements (indicated by connection 6) which, when the motor is turned in a first direction and in a second direction, cause the drive drum 3 and the shutter in a first direction S1 and a The second direction S2 moves.

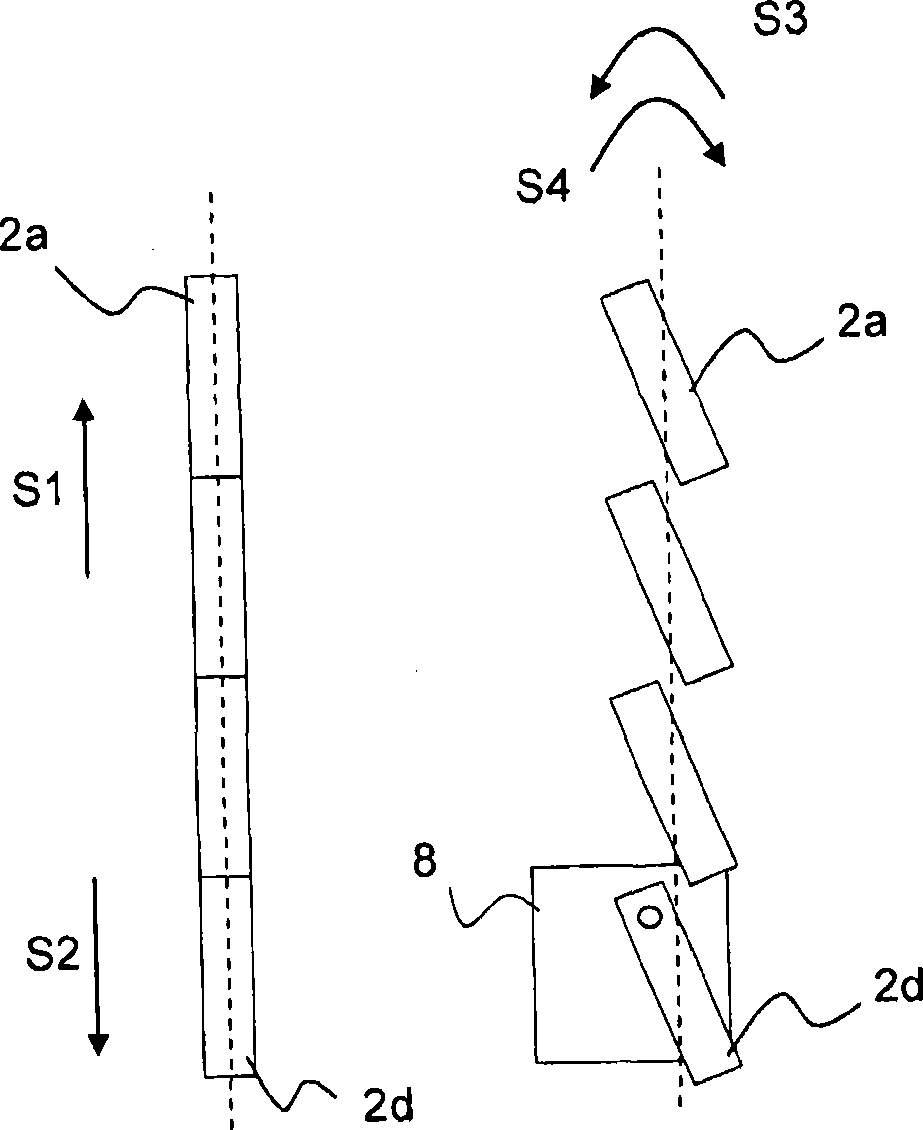

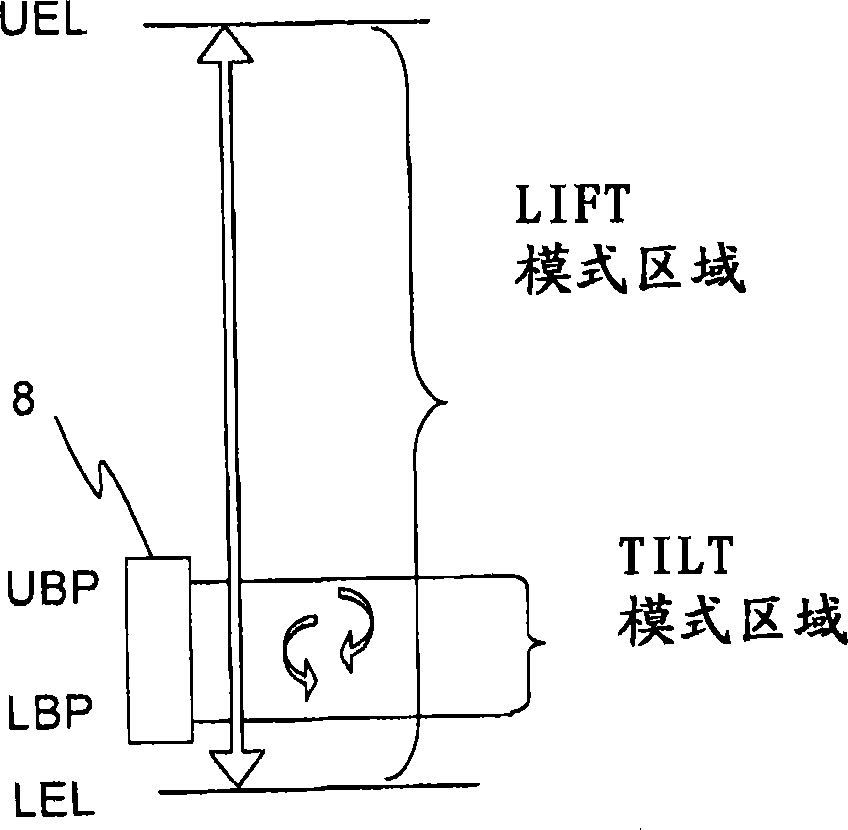

[0045] also expressed in figure 2 The louver on , comprises a plurality of mutually adjacent vanes 2a-2d and an inverting mechanism 8, or tumbler, for inverting these vanes according to their longitudinal axis XX. This mechanism 8 is used when the shutter is unfolded up to a particular flipped or oriented position of the blades BP. This inversion position is preferably a pre-recorded intermediate position in which a special blade, for example the final blade, is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com