Shallow poor subsoil composite foundation stabilization treatment method

A composite foundation and treatment method technology, applied in the field of geotechnical engineering, can solve the problems that the treatment method of a large-scale weak foundation cannot fully meet the requirements, the depth of the pile body is too deep, and the construction machinery is cumbersome. The effect of reducing post-construction settlement and miniaturizing construction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

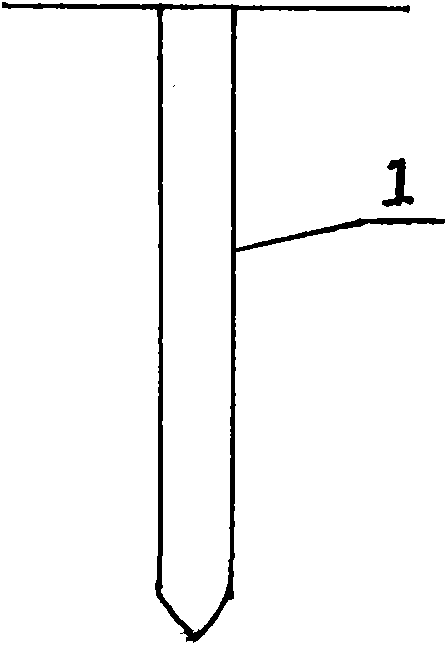

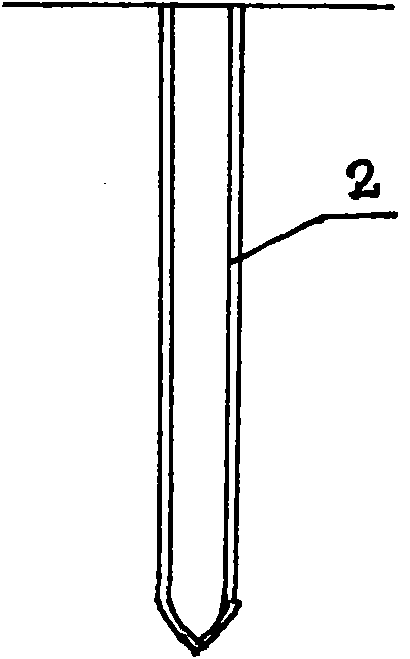

[0027] As shown in Figure 1, the geotechnical pipe bag laying steps: (1) as Figure 1a , use Luoyang shovel to form the hole, the hole forming standard: diameter Φ120mm, depth 4m, pile spacing 0.6m, triangular arrangement; (2) such as Figure 1b , Use the drill pipe to send the closed end of the geotechnical pipe bag with a diameter of 180mm and a length of 4.5m to the bottom of the hole.

[0028] The preparation steps of lime-mixed clay mixed filling material are as follows: (1) Select fresh block ash, water it for pre-digestion and pass it through a 5mm sieve; mix clay with clay excavated in situ, clay particles ≤ 15mm, remove visible organic matter cohesive soil (2) Lime and clay are mixed evenly in the mixing equipment according to the designed lime-soil ratio, and the amount of quicklime added is 8%.

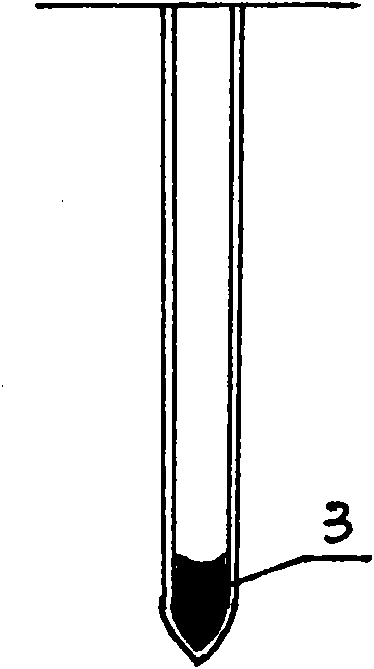

[0029] Such as Figure 1c and Figure 1d , The construction steps of compaction and compaction are: after mixing evenly, the lime soil filler is filled in layers along th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com