Lead support frame for binary division lead deicing through mechanical shock

A mechanical vibration, two-split technology, applied in overhead installation, cable installation, electrical components, etc., can solve the problems of poor clamping effect and low deicing efficiency, and achieve enhanced clamping effect, good deicing effect, and clamping effect. hold firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments

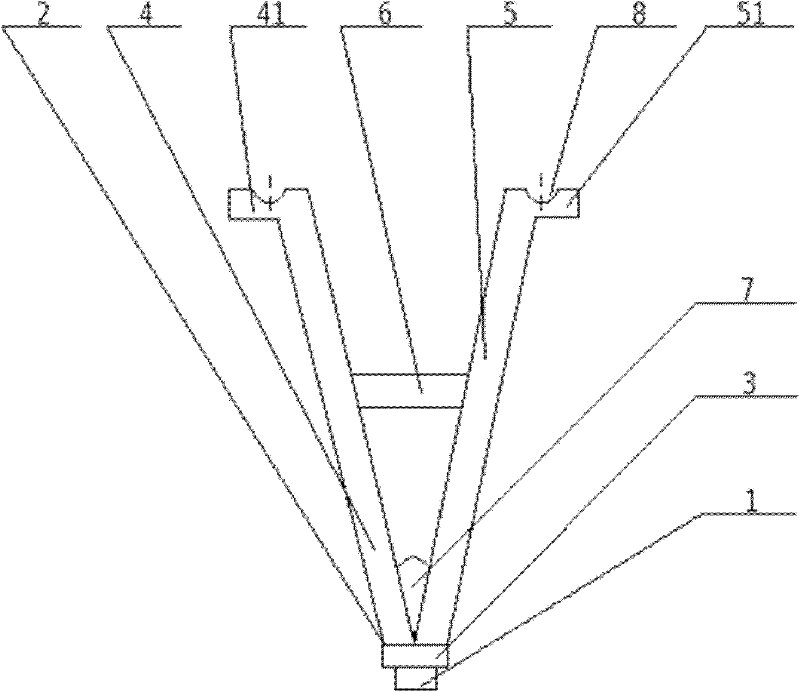

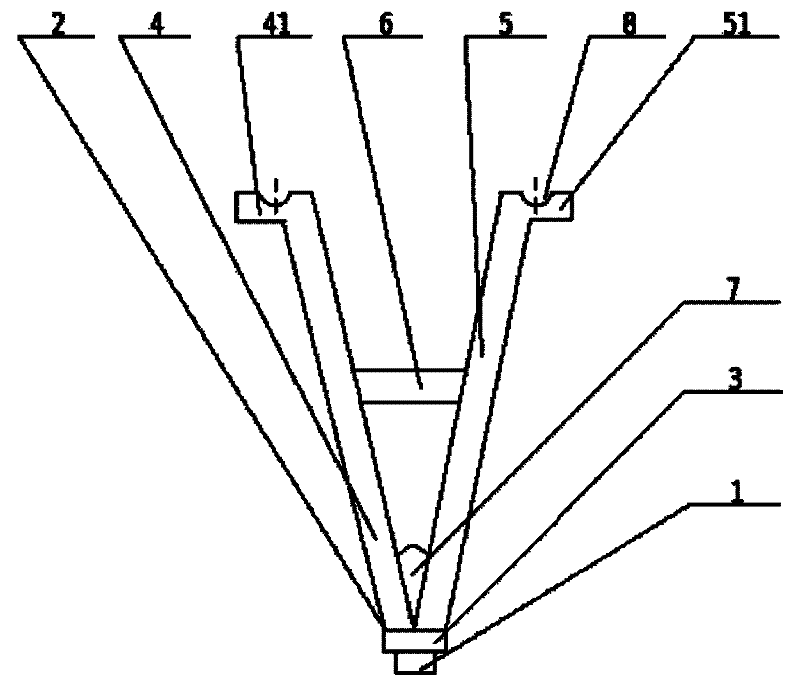

[0021] see figure 1 , a wire support frame for mechanical vibration deicing of two-split wires, including an ice-breaking head 1 and a clamping part 2 connected to each other, the clamping part 2 is a V-shaped or U-shaped structure, including a mounting table 3 and its The left supporting part 4 and the right supporting part 5 are symmetrically arranged on the top, and the left connecting part 41 and the right connecting part 51 are respectively arranged on the top ends of the left supporting part 4 and the right supporting part 5 .

[0022] A reinforcing beam 6 is arranged between the left support part 4 and the right support part 5 .

[0023] The left and right angle 7 formed between the left support part 4 and the right support part 5 is 10°-180°.

[0024] The size of the left-right angle 7 is 10°-90°.

[0025] The size of the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com