Automatic clutch device in electric screwdriver

An electric screwdriver, automatic clutch technology, used in screwdrivers, wrenches, manufacturing tools, etc., can solve problems such as no clutch device, transmission components and motor damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

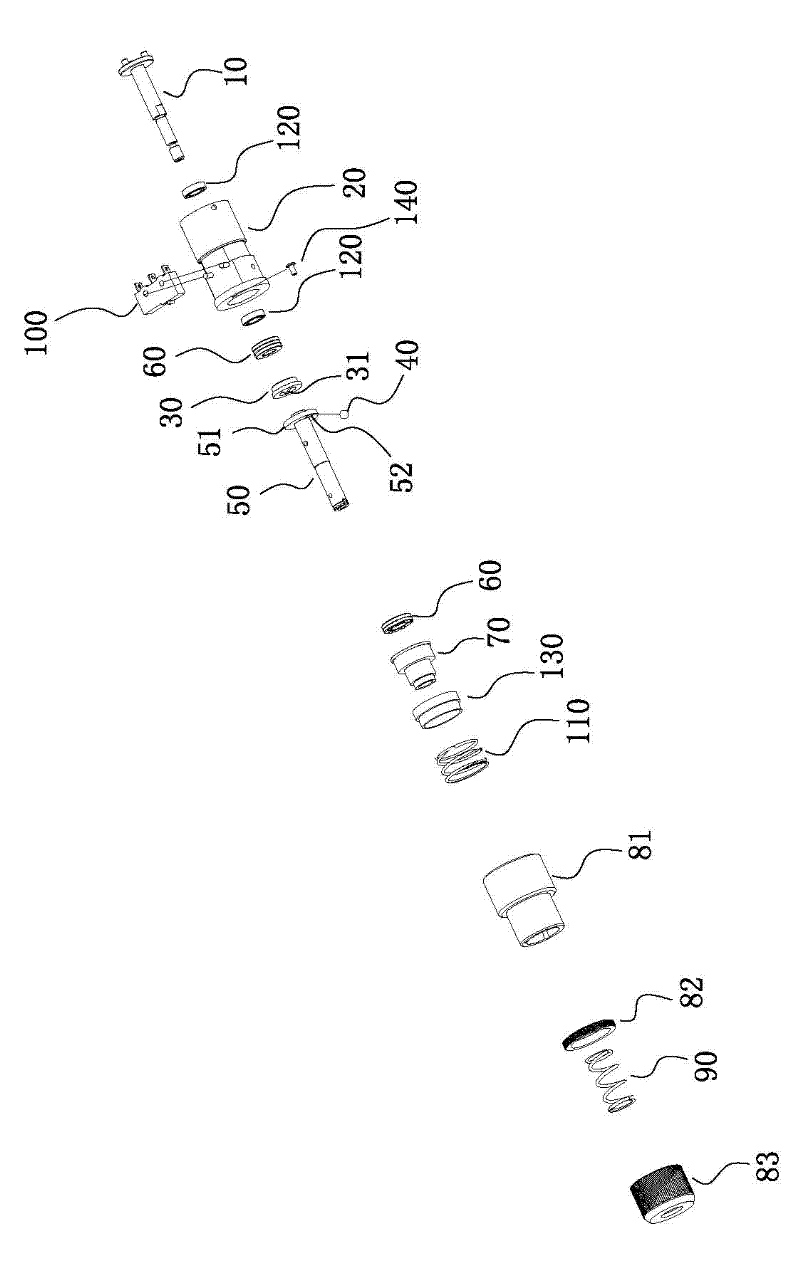

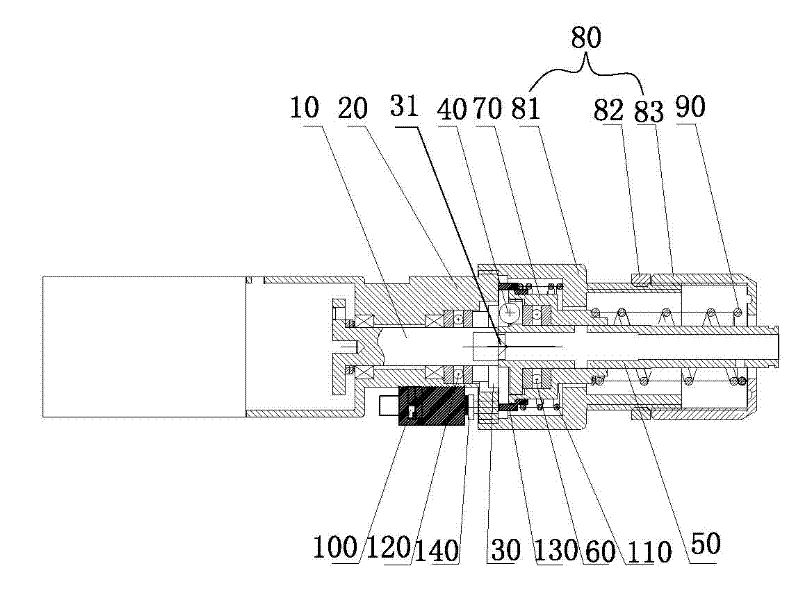

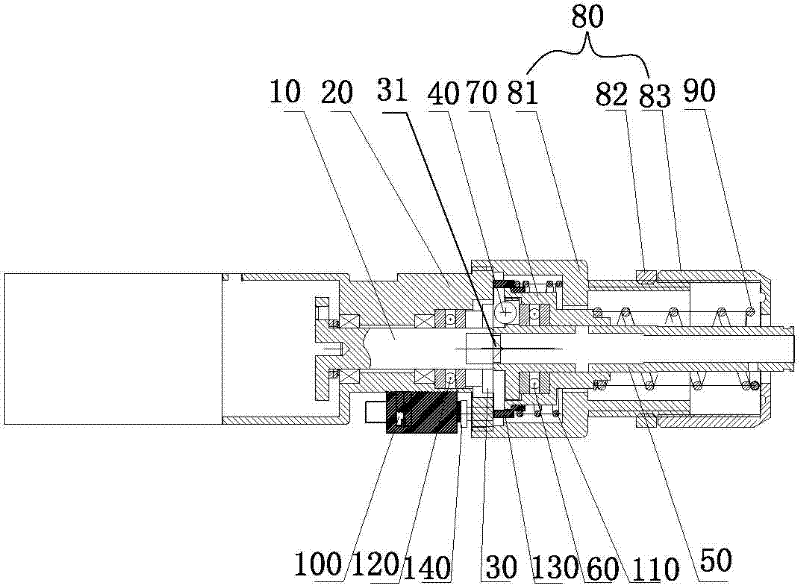

[0012] Such as Figure 1-2 As shown, the present invention includes: an automatic clutch device in an electric screwdriver, including: a drive shaft 10, a clutch barrel 20, a stop cam 30, a transmission ball 40, a transmission shaft 50, a thrust bearing 60, a spring seat 70, The shell assembly 80, the torsion spring 90, the micro switch 100, the drive shaft 10 is installed in the clutch barrel 20, the rear end of the drive shaft 10 is connected with the output shaft of the motor through the transmission device, and the front end of the drive shaft 10 is fixedly connected with a stop The eccentric position of the end face of the cam 30 and the stop cam 30 is formed with a stop drive block 31; the connecting end of the shell assembly 80 is fixedly connected with the clutch cylinder 20 by one or more parts, and is respectively in the cavity of the shell assembly 80. Installed with transmission ball 40, transmission shaft 50, thrust bearing 60, spring seat 70, torsion spring 90, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com