Electric clutch type winch

A clutch-type, electric technology, applied in hoisting devices, clockwork mechanisms, etc., can solve the problems of unusable and exhausted automatic clutch devices, and achieve the effect of simple and reasonable structure, low power consumption and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

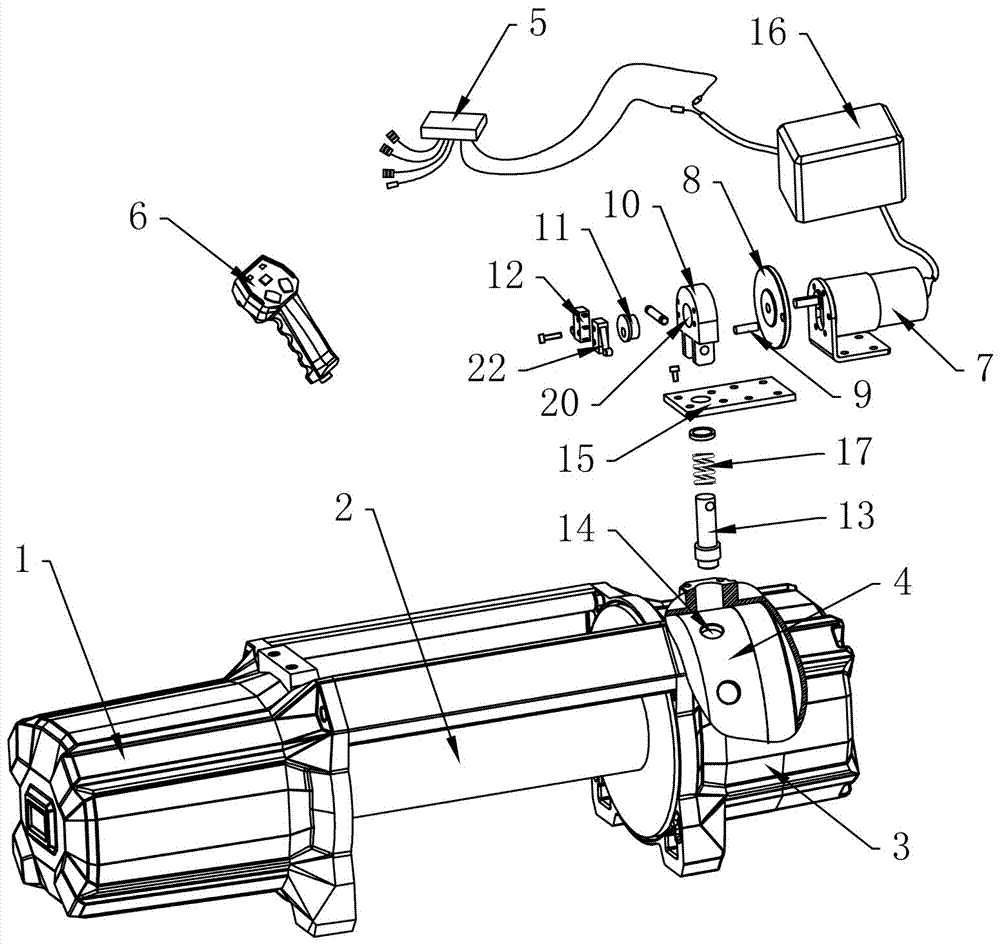

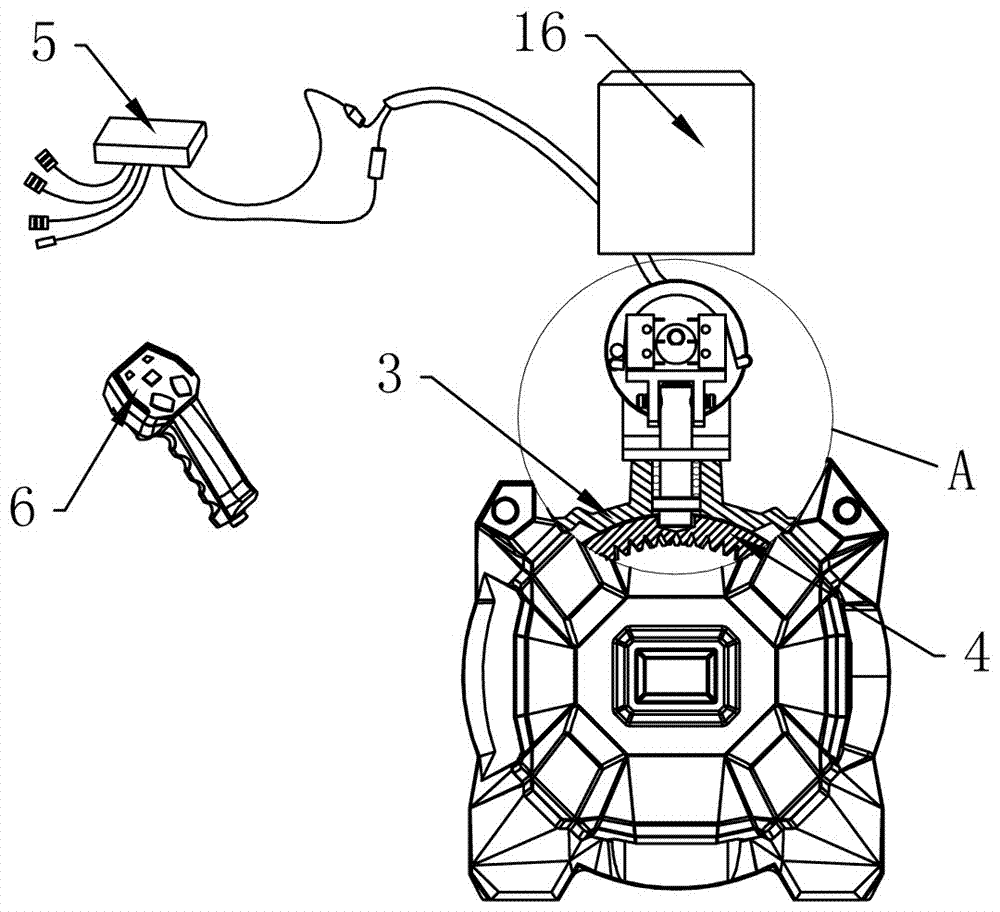

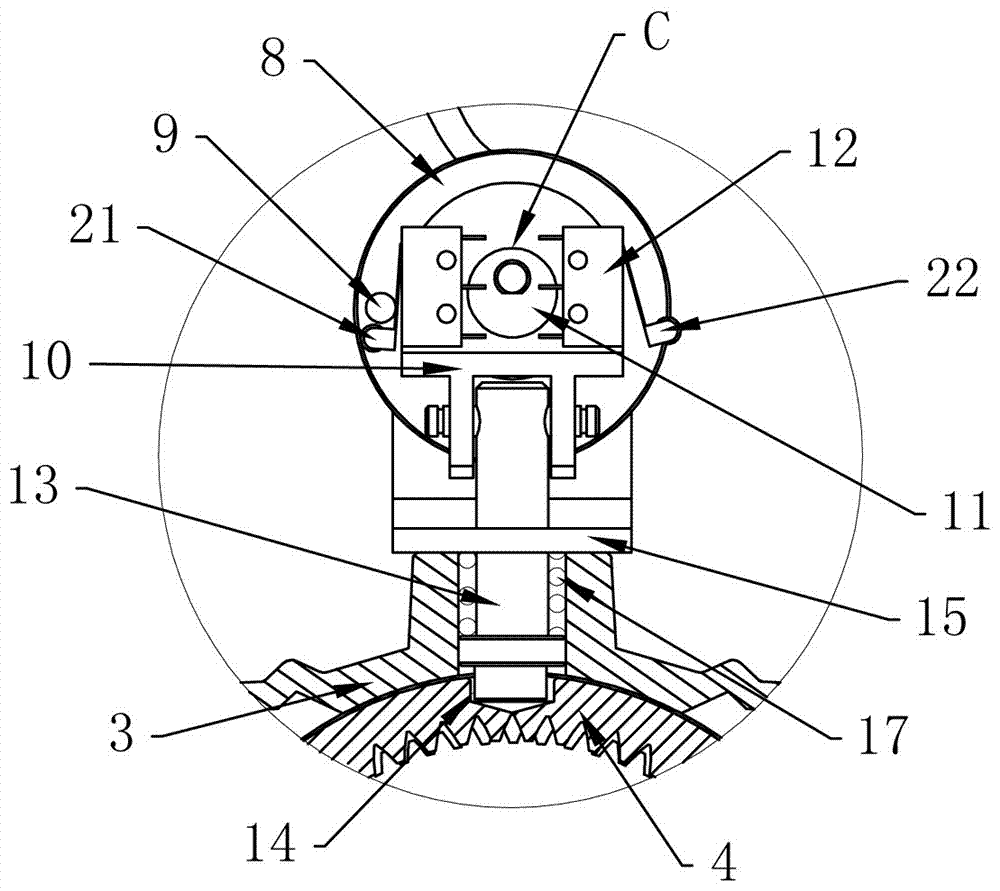

[0028] Embodiment one, such as Figure 1 to Figure 5 As shown, an electric clutch type winch includes a motor 1, a hoist drum 2 and a gear box 3, the hoist drum 2 is arranged between the motor 1 and the gear box 3, the hoist drum 2 is provided with a transmission shaft, and the gear box 3 is equipped with a deceleration mechanism, the deceleration mechanism includes a planetary deceleration assembly connected to the hoist drum 2, a small inner ring gear 4 sleeved outside the planetary deceleration assembly, the small internal gear 4 meshes with the planetary deceleration assembly, and the transmission shaft The front end is connected to the output shaft of the motor 1, and the rear end of the transmission shaft is connected to the planetary reduction assembly. The gearbox 3 is provided with a clutch control device. The clutch control device includes a direct pin 13, and one end of the direct pin 13 extends into the gearbox 3. , and the outer wall of the small inner ring gear 4...

Embodiment 2

[0032] Embodiment two, such as Figure 6 As shown, the difference from Embodiment 1 is that the eccentric member includes a turntable 8 and an eccentric shaft 18, the center of the turntable 8 is fixedly connected to the output shaft of the geared motor 7, one end of the eccentric shaft 18 is eccentrically fixed to the turntable 8, and the other end Extend into the linkage hole 20.

[0033] The working principle of this embodiment is to use the remote control 6 to drive the reduction motor 7 to work, the reduction motor 7 drives the turntable 8 to rotate, and the eccentric shaft 18 makes the linkage frame 10 move up and down, so as to drive the direct pin 13 to limit and cooperate with the small inner ring gear 4 or Break away from the limit fit, so that the clutch control device realizes the automatic clutch function, set the trigger lever 9, after touching the limit switch 12 each time, the power supply of the geared motor 7 can be automatically cut off

Embodiment 3

[0034] Embodiment three, such as Figure 7 As shown, the difference from Embodiment 1 is that the control mechanism is a time control module 19 integrated in the control circuit of the signal receiver 5 .

[0035] The working principle of this embodiment is to use the remote control 6 to drive the geared motor 7 to work, and the geared motor 7 drives the eccentric wheel 11 to rotate, so that the linkage frame 10 moves up and down, and drives the direct pin 13 to cooperate with the small inner ring gear 4 or to break away from the limit Cooperate, so that the clutch control device realizes the automatic clutch function, set the time control module 19, after the signal receiver 5 receives the instruction from the remote controller 6, the reduction motor 7 rotates, and the eccentric wheel 11 rotates at the same time, the linkage frame 10 rises, and the eccentric The highest point of the wheel 11 reaches the top dead center C, and now the signal receiver 5 automatically cuts off t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com