Valve rocker for automobile engine

A technology of automobile engine and valve rocker arm, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of easy heat damage, loud noise, and easy wear and tear of the convex part of the valve rocker arm, so that it is not easy to wear and tear. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

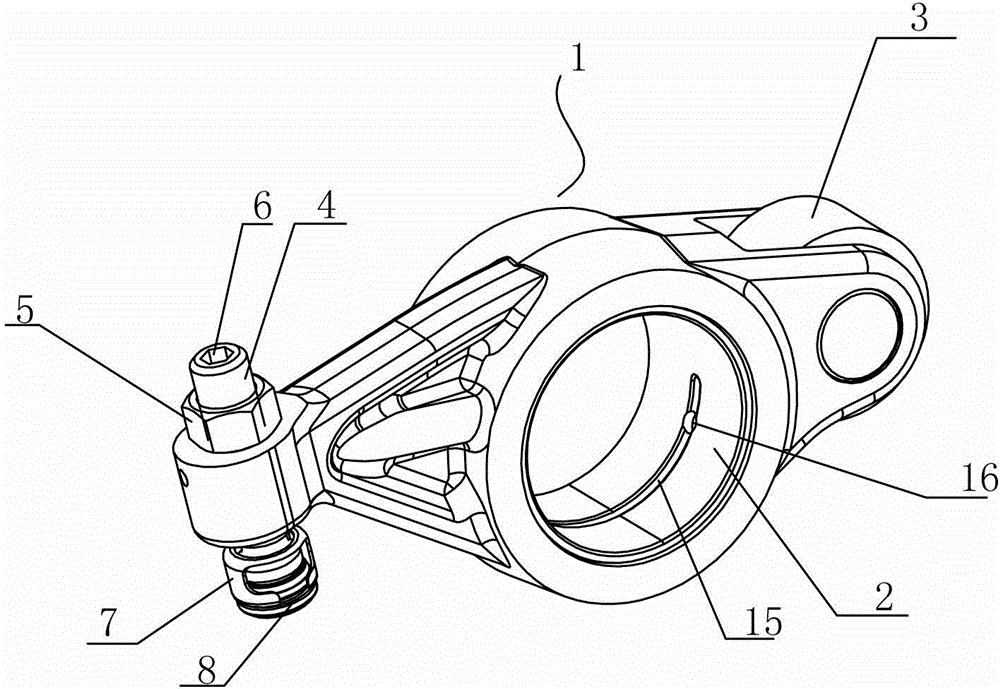

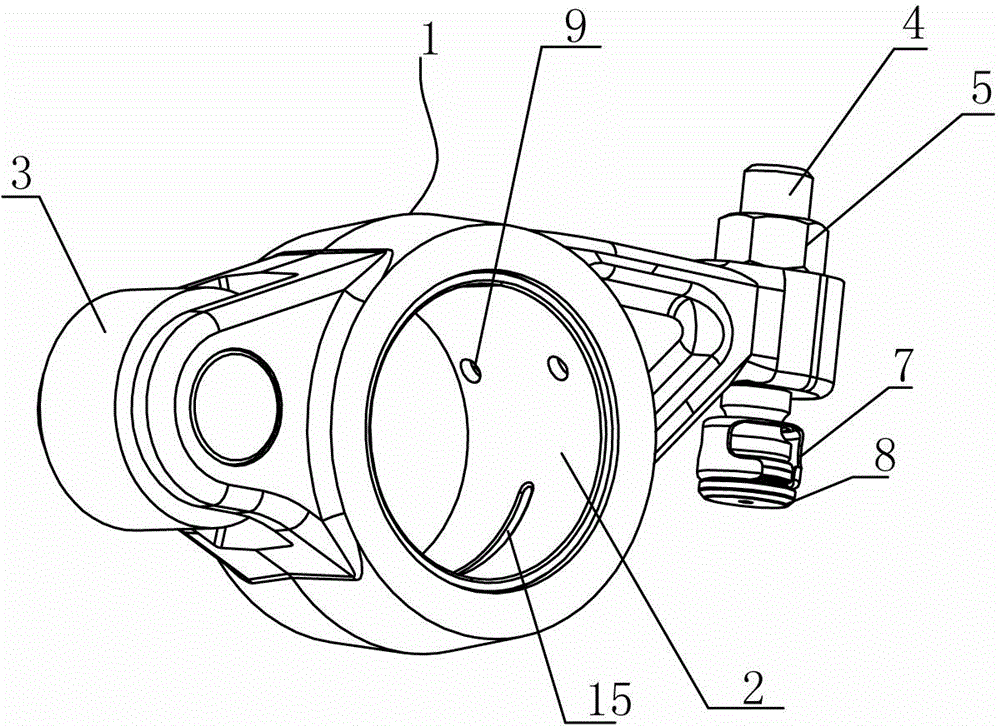

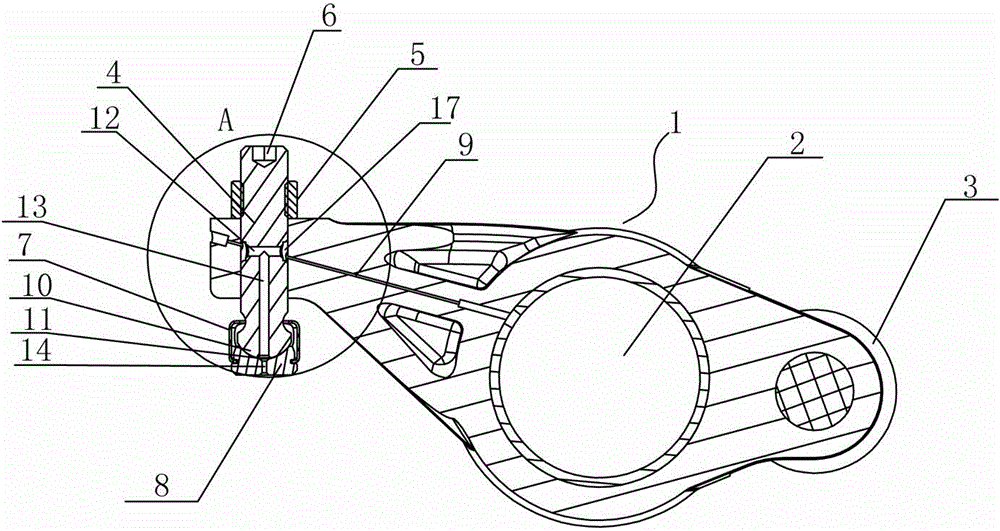

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 shown;

[0024] The valve rocker arm of the automobile engine of the present invention comprises a rocker arm body 1, which is provided with a shaft hole 2 that fits with the main shaft in clearance, and one end of the rocker arm body 1 is provided with a valve rod for supporting the valve. The push rod 4 for adjusting the valve clearance, and the other end of the rocker arm body 1 is provided with a roller 3 for contacting with the crankshaft cam of the engine. The lower end of the rod 4 is provided with a ball head 10, the ball head 10 is provided with a spacer 8, and the upper end surface of the spacer 8 is provided with a concave arc surface 11 whose shape and size match the surface of the ball head 10, so that A connecting frame 7 is arranged between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com