Mechanical transmission of electric vehicle

A technology for mechanical transmissions and electric vehicles, applied in mechanical equipment, mechanical control devices, instruments, etc., to solve problems such as reduced power and torque, and easy burnout of motors and control systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

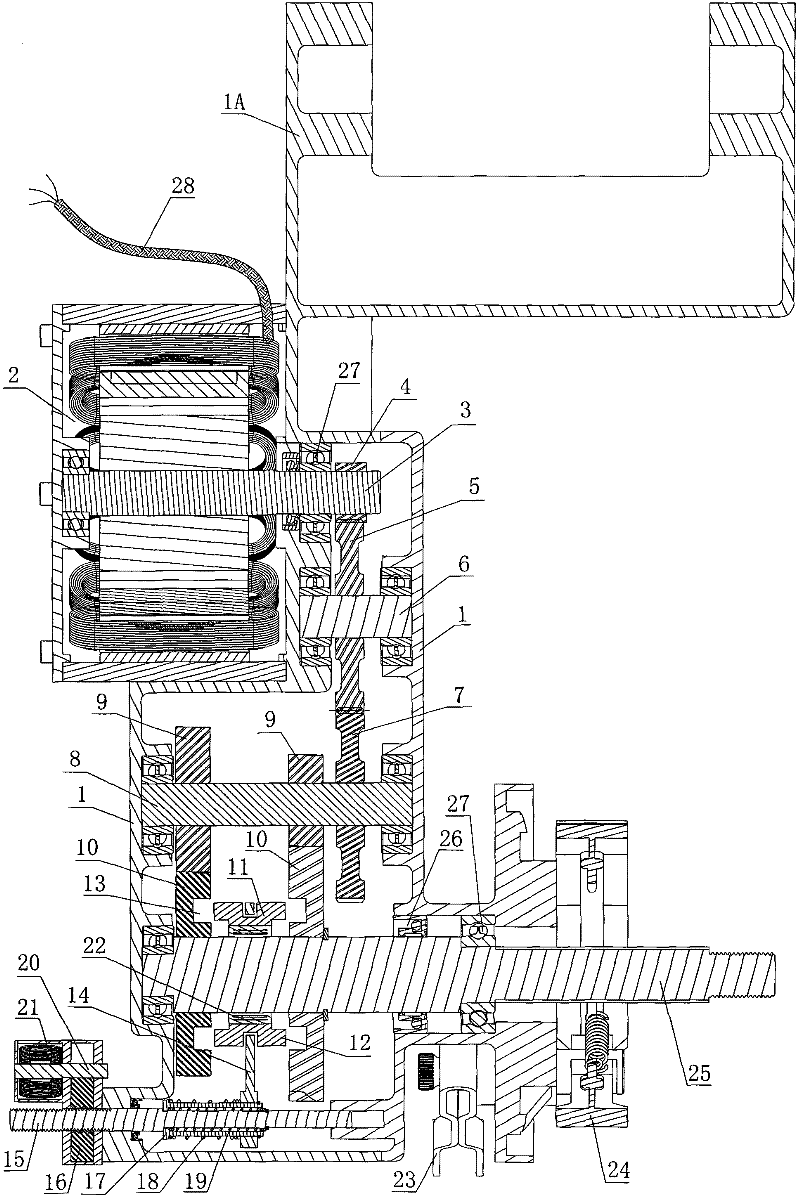

[0037] Such as Figure 1 to Figure 9 Shown is the first embodiment of the electric vehicle mechanical transmission of the present invention, the electric vehicle mechanical transmission includes a box body 1, the box body 1 is connected with a flat fork 1A, and the flat fork 1A is used to connect the entire machine to the vehicle frame superior.

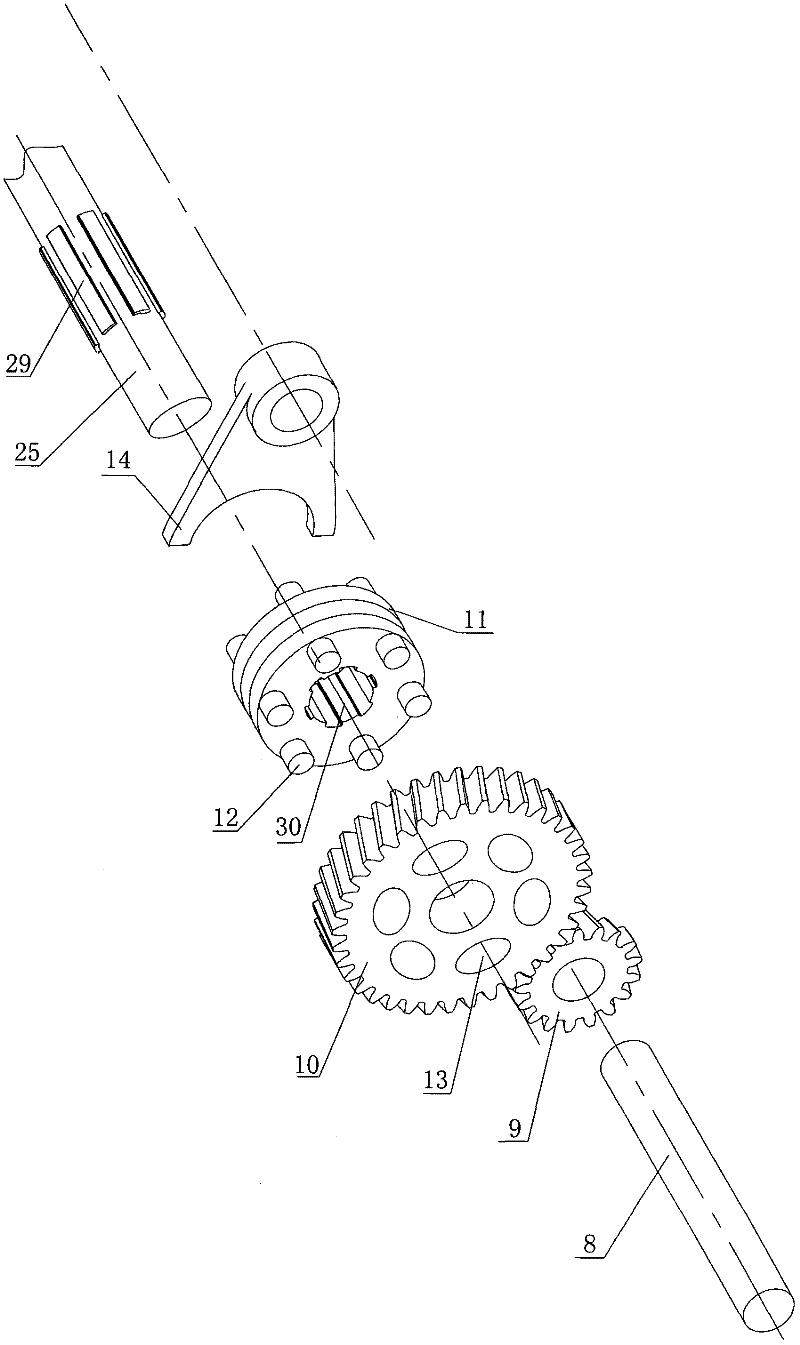

[0038] Such as figure 1 As shown in , the output shaft 25 is provided with at least two output gears 10, the output gears 10 can rotate on the output shaft 25, and the diameters of each output gear 10 are different. The main shaft 8 is correspondingly fixed with a driving gear 9 meshing with the output gear 10 for transmission. The present invention is provided with two output gears 10 on the output shaft 25, and the output gears 10 are installed on the output shaft 25 through a snap spring.

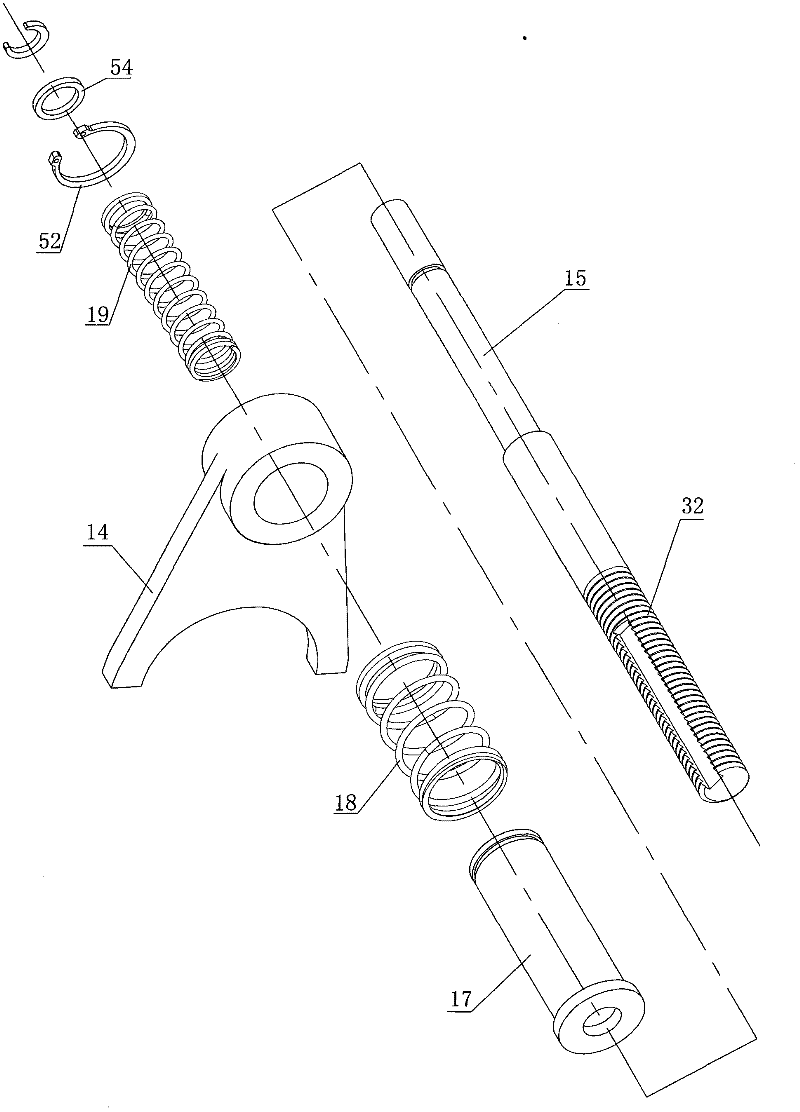

[0039] Such as figure 2 As shown in , the output shaft 25 is provided with a keyway 29, the driven sleeve 11 is set on the keyway 29, the...

Embodiment 2

[0053] Such as Figure 10 , Figure 11 Shown in is the second embodiment of the electric vehicle mechanical transmission of the present invention, which is different from Embodiment 1 in that the driven sleeve 11 is not arranged on the output shaft 25 but on the main shaft 8 .

[0054] Such as Figure 10 As shown in , the main shaft 8 is provided with at least two driving gears 9, the driving gears 9 can rotate on the main shaft 8, and the diameters of each driving gear 9 are different. The output shaft 25 is correspondingly fixed with the output gear 10 meshing with the drive gear 9 for transmission. The present invention is provided with two driving gears 9 on the main shaft 8, and the driving gears 9 are installed on the main shaft 8 through a snap spring.

[0055] Such as Figure 11 As shown in , the main shaft 8 is provided with a keyway 29, the driven sleeve 11 is set on the keyway 29, the driven sleeve 11 is provided with a keyway hole 30, the driven sleeve 11 can s...

Embodiment 3

[0069] Such as Figure 12 Shown in is the third embodiment of the electric vehicle mechanical transmission of the present invention, which is different from Embodiments 1 and 2 in that the driven sleeve 11 is not provided on the main shaft 8 or the output shaft 25, and the output shaft 25 and the high-speed output An electromagnetic clutch 42 is arranged between the gears 44 . The inner hole of the electromagnetic clutch 42 is provided with a spline, and the main shaft 8 cooperating with the spline also has a spline. The electromagnetic clutch 42 can move axially on the output shaft 25 .

[0070] Described output shaft 25 is provided with high-speed output gear 44, and high-speed output gear 44 can rotate on output shaft 25, and low-speed output gear 45 is then fixed on the output shaft 25, and the diameter of each output gear is different. The main shaft 8 is correspondingly fixed with a high-speed driving gear 46 meshing with the high-speed output gear 44. The low-speed driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com