Indoor high-voltage isolating switch static contact

A technology of isolating switch and internal high voltage, which is applied in the direction of electric switch, contact, contact heating/cooling, etc. It can solve the problems of high resistance of assembly contact surface, heating of switch operation state, burning out of contact fingers and contact seats, etc., and achieves Reduce production difficulty and cost, prolong service life and reduce contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

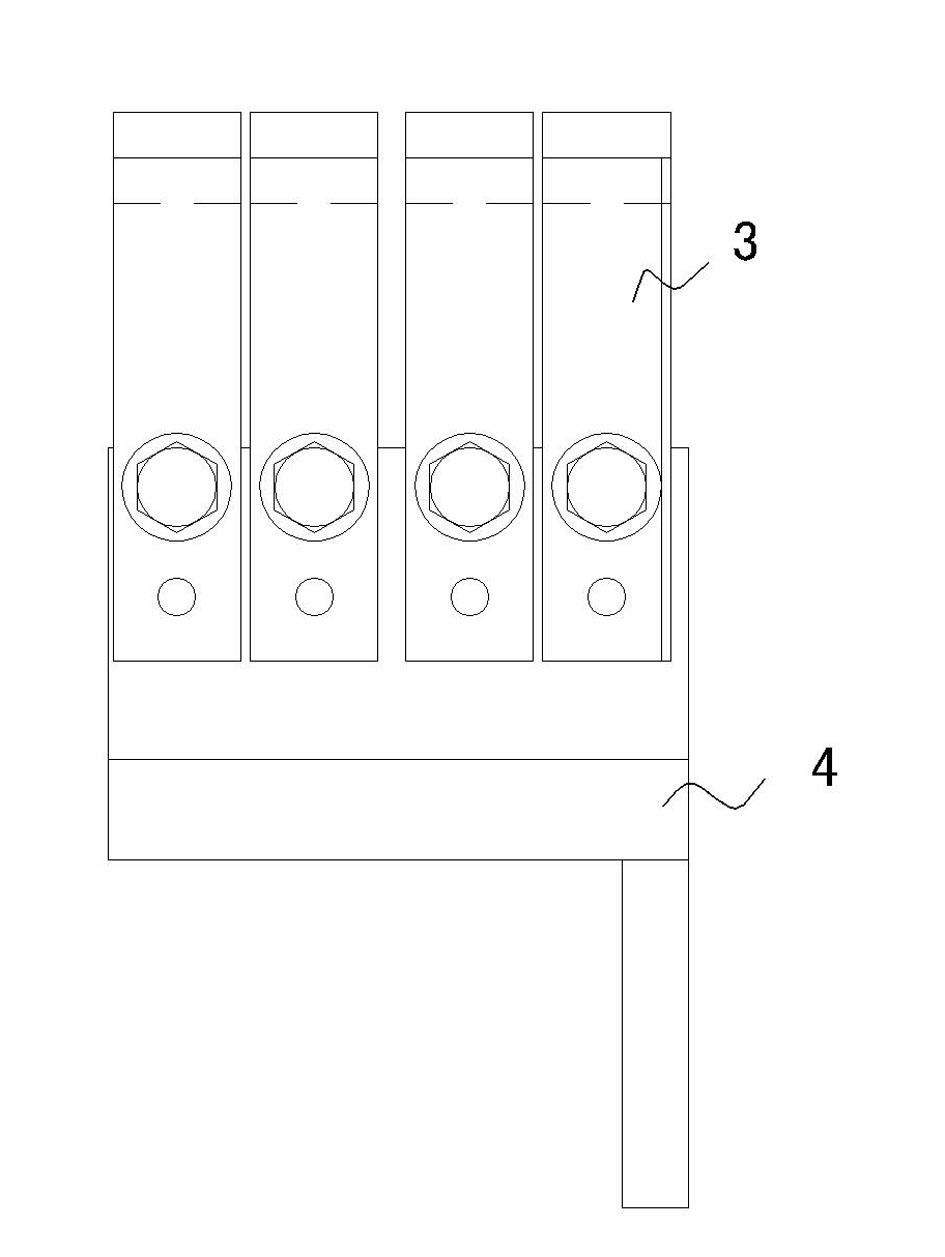

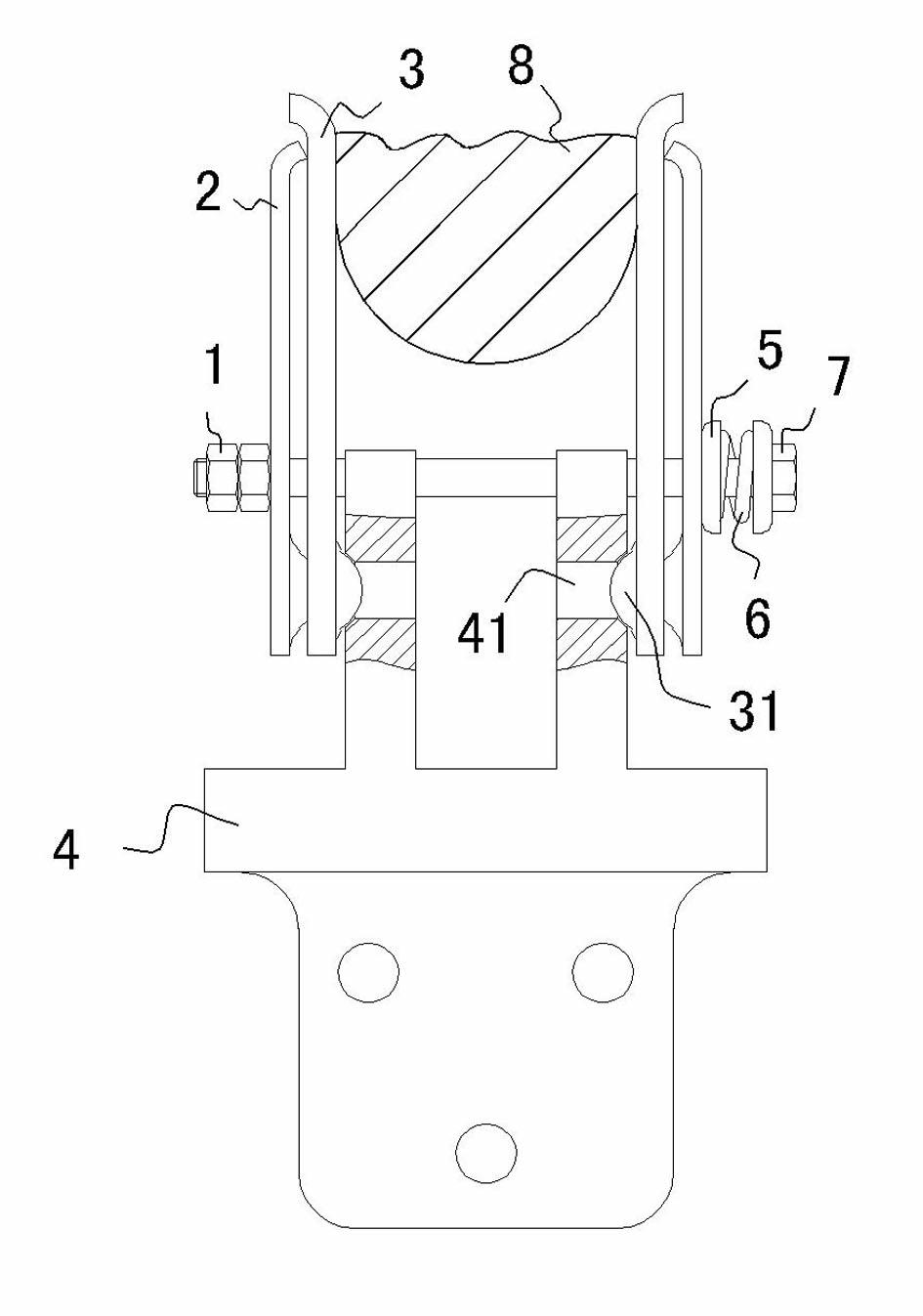

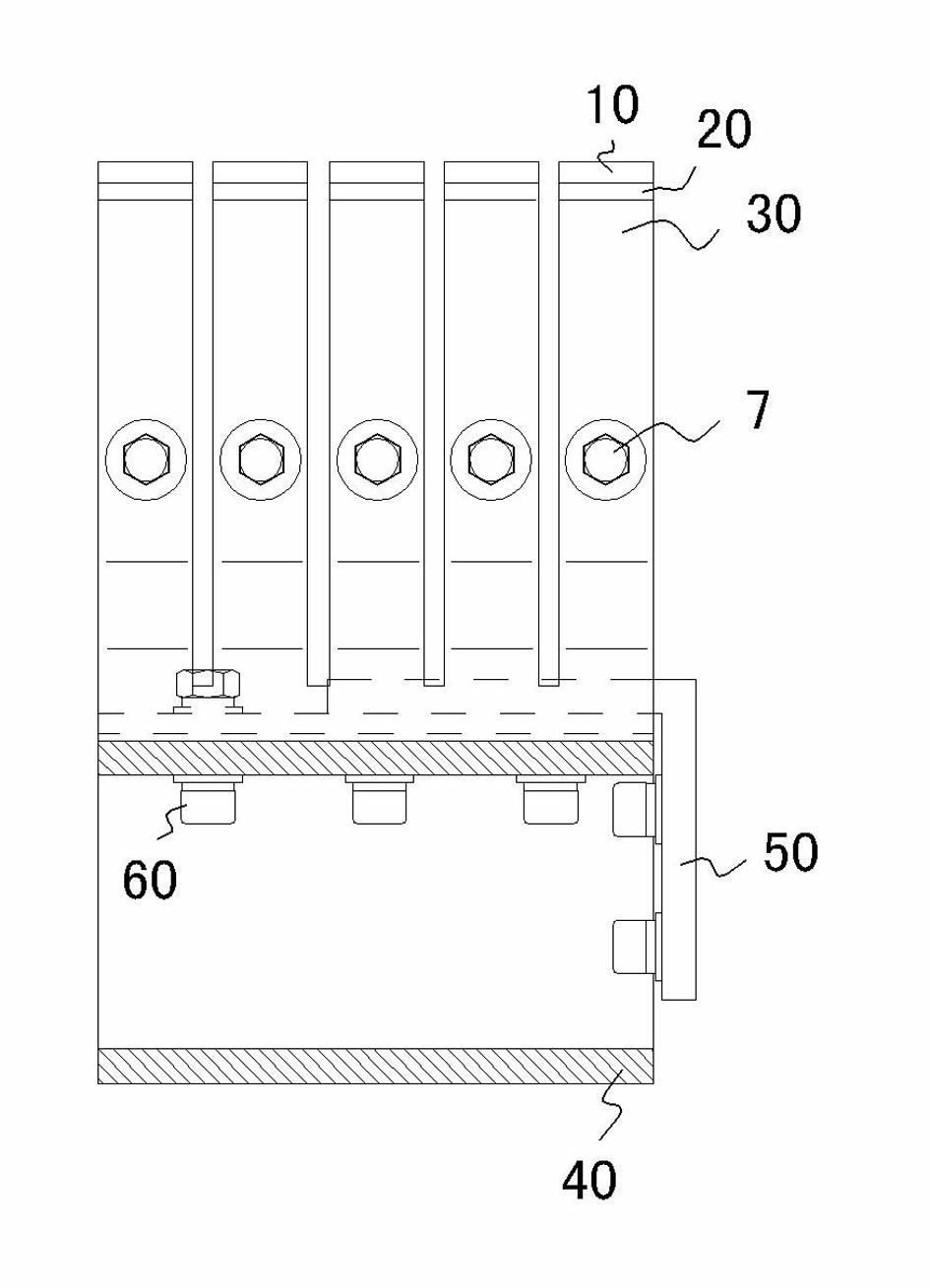

[0021] see image 3 , Figure 4 . The five pairs of contact fingers 10 are generally flat-bottomed U-shaped parts, and are integral elements, and the bottom of the contact finger 10 is enlarged along the axial direction of the screw rod 7, which is conducive to improving stability and expanding the contact surface. The integral contact finger 10 is formed by stamping with a special mold, and has good consistency. Matching the shape of the outer wall of the flat-bottomed U-shaped piece, the splint 20 is in close contact with the outer wall of the flat-bottomed U-shaped piece. The waist of contact finger 10, splint 20 and magnetic lock plate 30 is elastically locked by nut 1, spring seat 5, spring 6, and screw rod 7. The assembly is all very convenient for processing and assembling, and has low requirements.

[0022] The contact seat 40 is located at the bottom of the contact finger 40 and is made of a 140x100x10 square copper profile. Compared with the original contact seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com