Bridge type rotary bag stacker

A technology of a stacker and a rotary mechanism, which is used in the stacking, transportation and packaging of objects, storage devices, etc., can solve the problems of wasting warehouse space and inability to use warehouses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

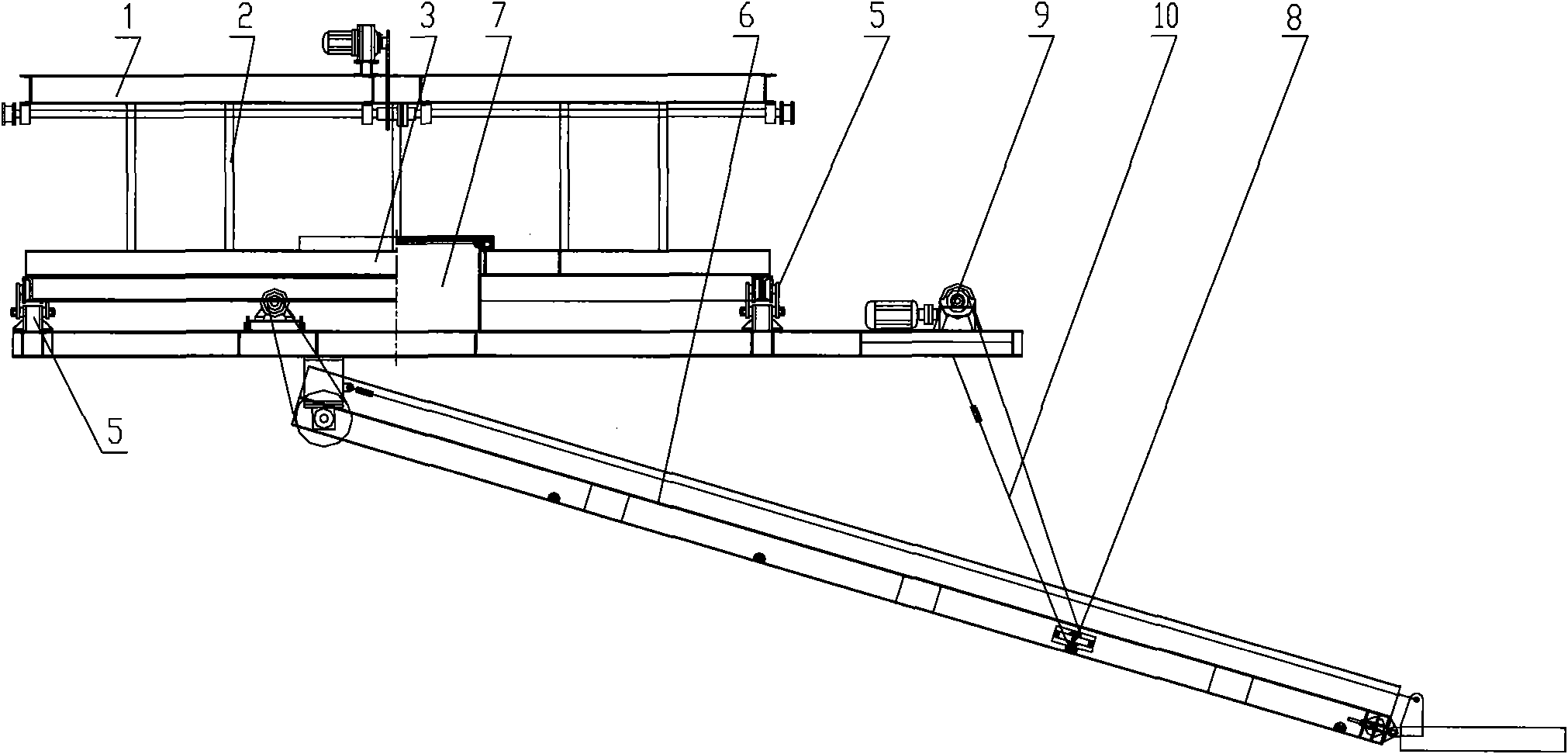

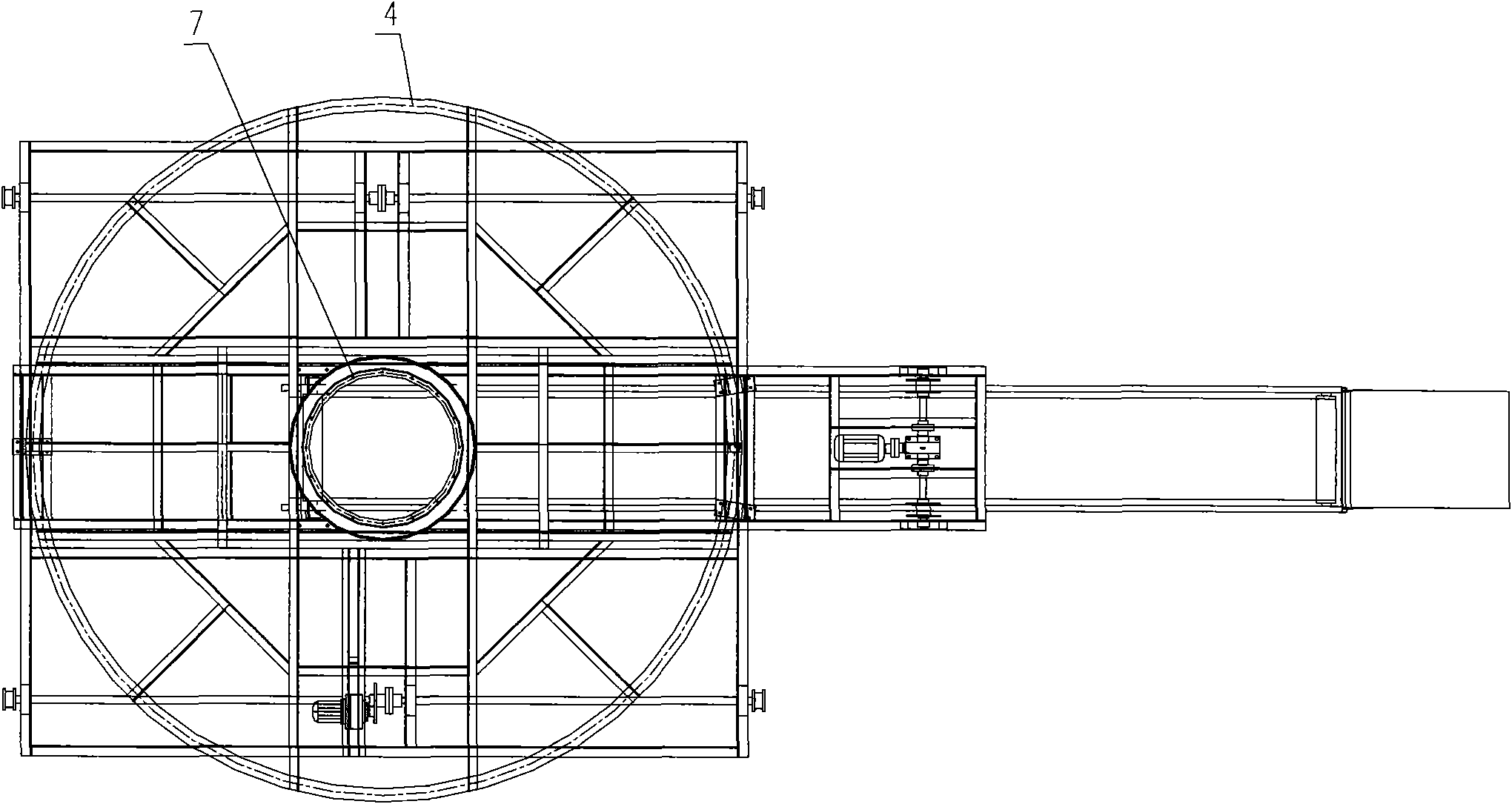

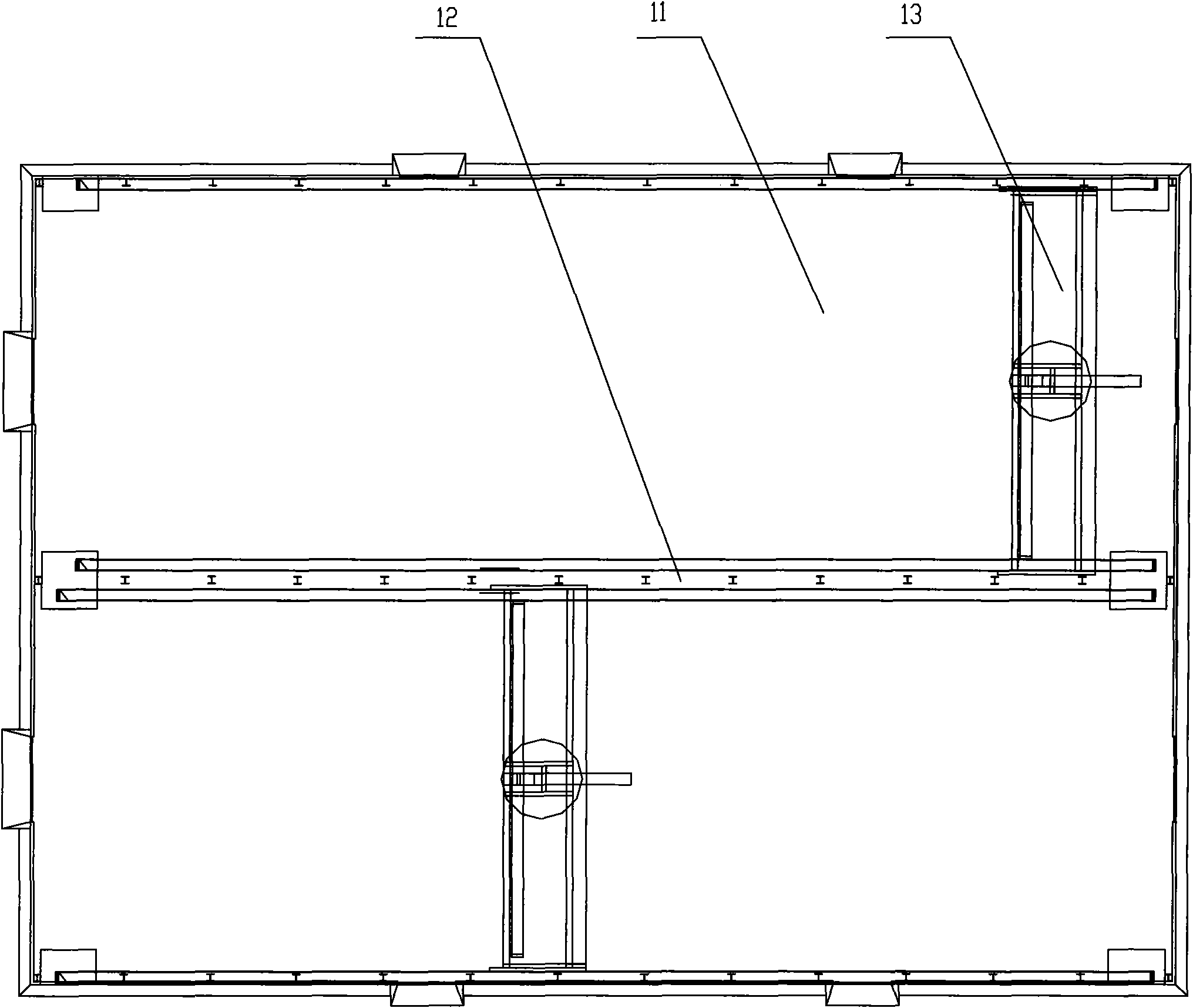

[0014] Such as figure 1 , 2 A bridge-type rotary stacking machine shown is provided with a trolley slideway 1 and a trolley frame 2. The lower part of the trolley slideway 1 is connected by a trolley frame 2 and a rotary mechanism 3 that can rotate 360°. A conveying hole 7 is provided in the middle of the slewing mechanism 3, and a circular track 4 and at least three pulley devices 5 are arranged inside the slewing mechanism 3, and the pulley device 5 can drive the bridge type rotary bale stacker in the circular track 4. The half part rotates 0-360° (but considering the practicability of the equipment, it is positioned at 270° during installation), the lower part of the turning mechanism 3 is connected to a sliding belt conveyor 6 through a hinge, and the turning mechanism 3 usually adopts Manually control the middle part of the sliding bag belt conveyor 6 to be provided with a lifting mechanism, and the lifting mechanism is composed of a driven wheel 8 arranged on the track ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com