Full-dry high count armour indoor and outdoor optical cable

A technology with large number of cores and armored chambers, applied in the direction of fiber mechanical structure, etc., can solve problems such as construction trouble, and achieve the effect of convenient laying, easy connection and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

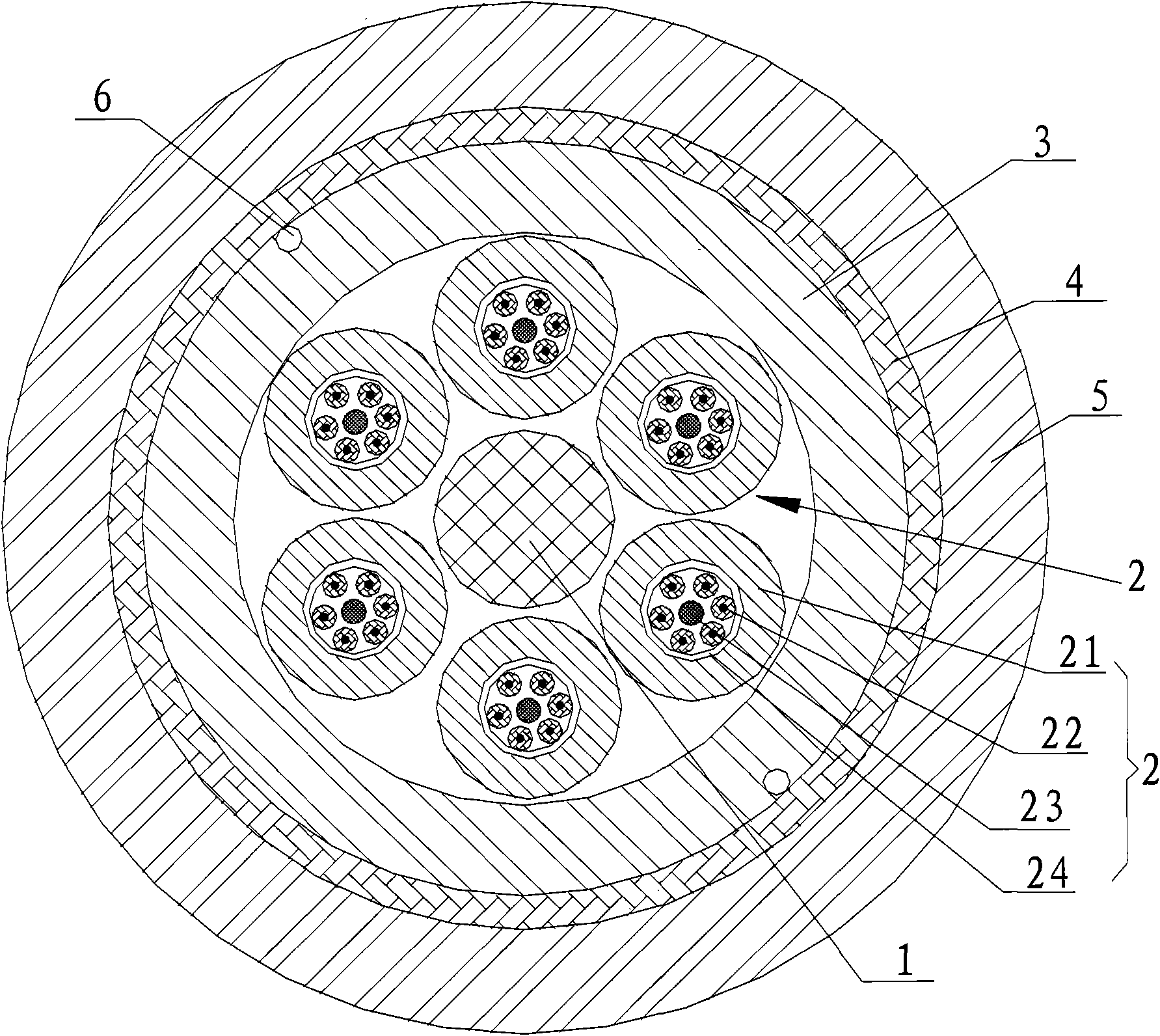

[0013] Below in conjunction with accompanying drawing, illustrate in detail the specific content of the present invention:

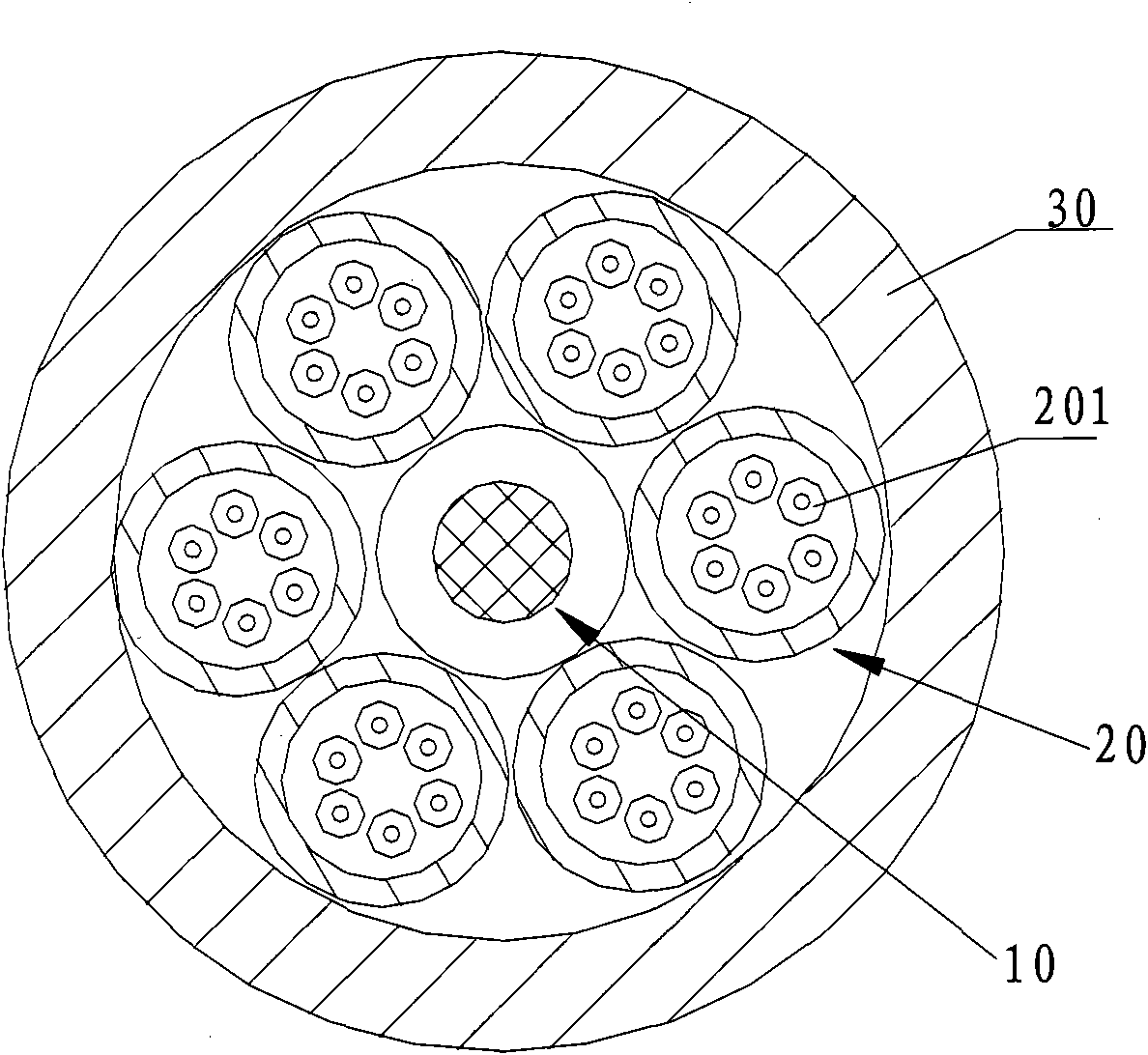

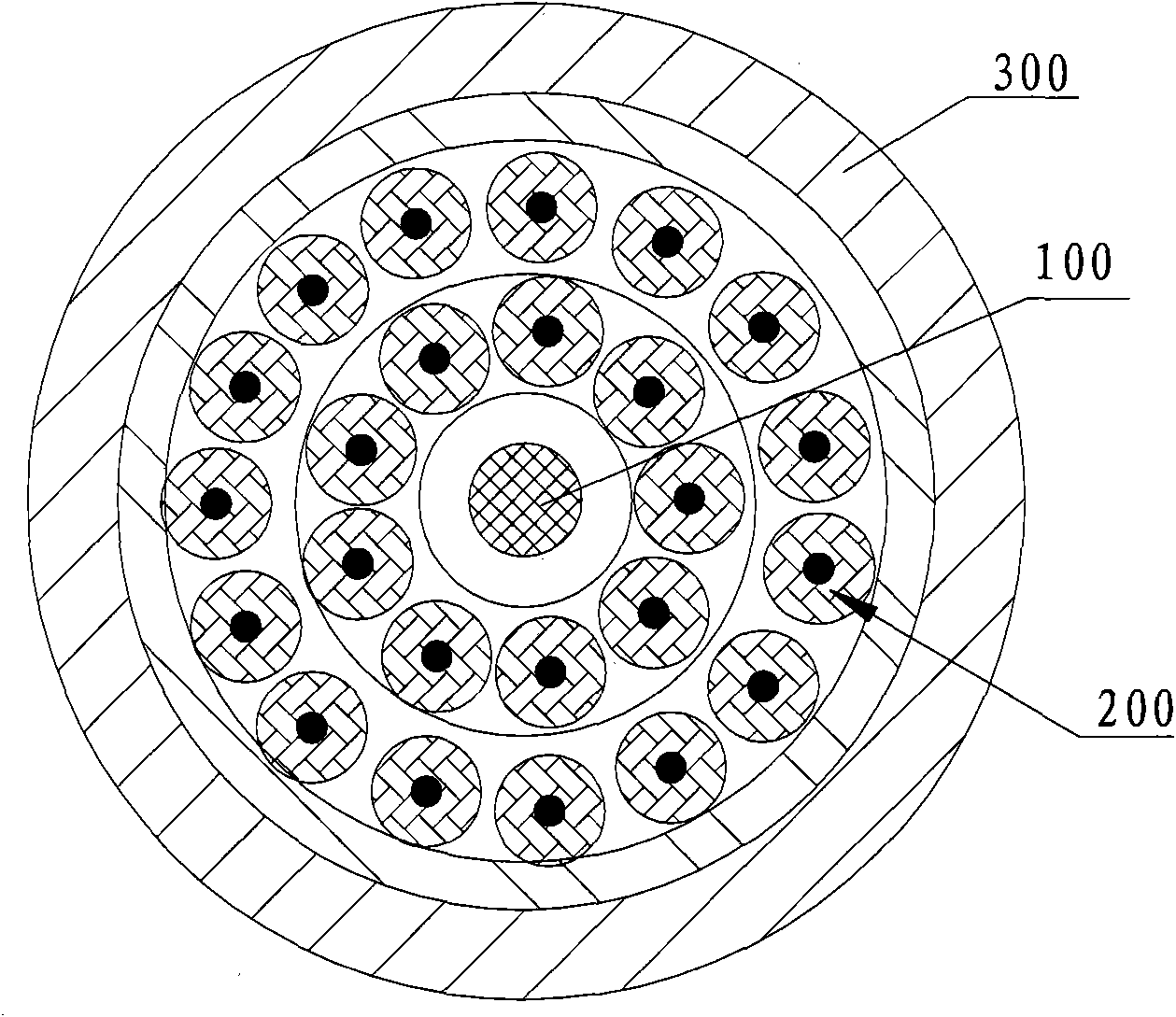

[0014] Such as image 3 The optical cable shown includes a central strengthening member 1, a plurality of unit cables 2 twisted and arranged on the outer periphery of the strengthening member 1, a PVC inner sheath 3 and a metal armor layer 4 that are sequentially covered from the inside to the outside. And the PVC outer sheath 5, wherein, each unit cable 2 comprises a loose tube 21, a plurality of tight-buffered optical fibers 22 arranged in the loose tube 21, an aramid yarn 23 that binds a plurality of tight-buffered optical fibers 22 tightly, In order to further strengthen the strength of the optical cable, a reinforcing rod 25 may also be arranged at the center of each unit cable 2 .

[0015] In this embodiment, there are six unit cables 2, and there are six tight-buffered optical fibers 22 in each unit cable 2, and the six tight-buffered optical fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com