Focusing device in long-focus and heavy-caliber optical system

An optical system and large-aperture technology, applied in optics, optical components, installation, etc., can solve problems such as difficult to determine coaxial precision, large focusing error, and difficult installation and adjustment, and achieve easy installation and adjustment, simple structure, and adjustment The effect of high focus precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

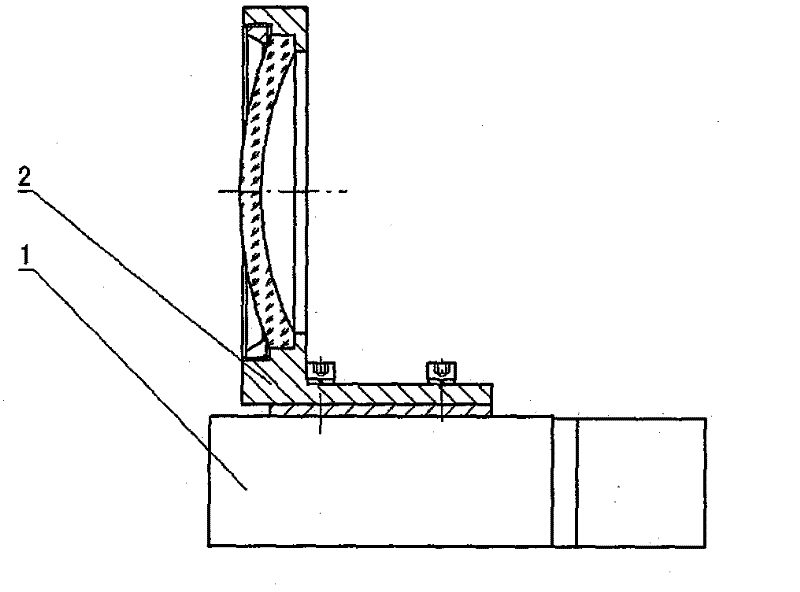

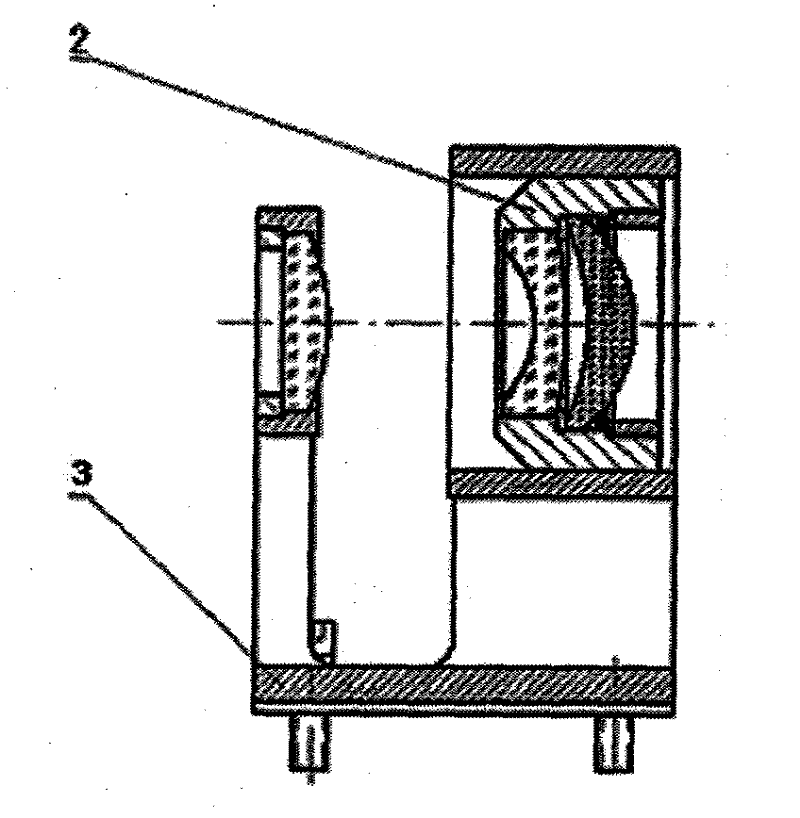

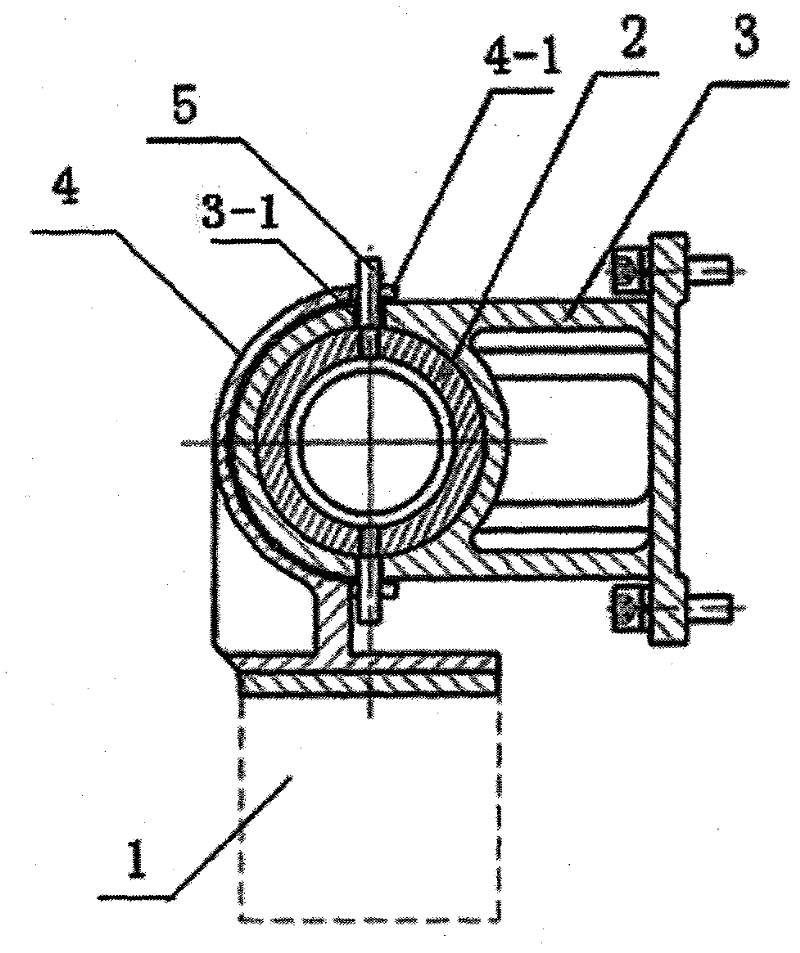

[0014] Specific implementation mode one: combine Figure 2 to Figure 6 Illustrate this embodiment, the focusing device in the optical system with a long focal length and a large aperture includes an electronically controlled displacement platform 1 and a focusing lens group 2, it also includes a slide rail seat 3, a shift fork 4 and two cylinders 5, the described The focusing lens group 2 is arranged in the slide rail seat 3, the shift fork 4 is arranged on the outside of the slide rail seat 3, and the shift fork 4 is fixedly connected with the electronically controlled displacement platform 1; the focusing lens group 2 and the two cylinders 5 adopt Threaded connection, the two ends of the shift fork 4 are respectively provided with U-shaped grooves 4-1, two long slot holes 3-1 are opened on the slide rail seat 3, and the cylinder 5 passes through the long slots on the slide rail seat 3 in turn The hole 3-1 and the U-shaped groove 4-1 on the shift fork 4; the slide rail seat 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com