Ceramic tile flatness on-line detection method

A detection method and technology of ceramic tiles, which are applied in the field of detection using non-contact distance measuring sensors as data collection, and online detection of ceramic tile flatness, can solve the problems of high manual measurement costs, low efficiency, large errors, etc., and achieve improvement Online detection efficiency, satisfying the effect of rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

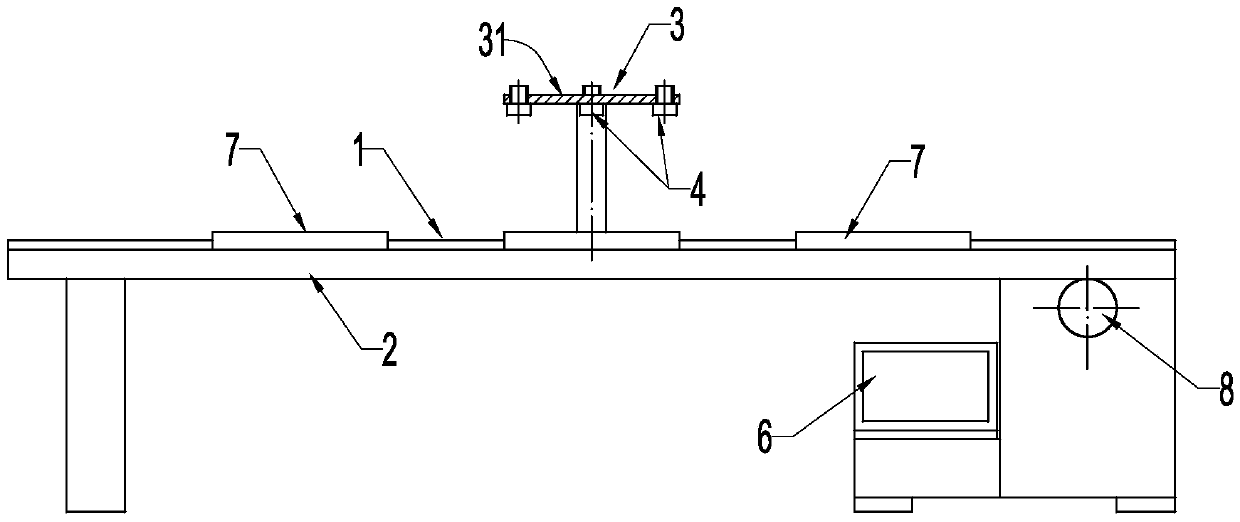

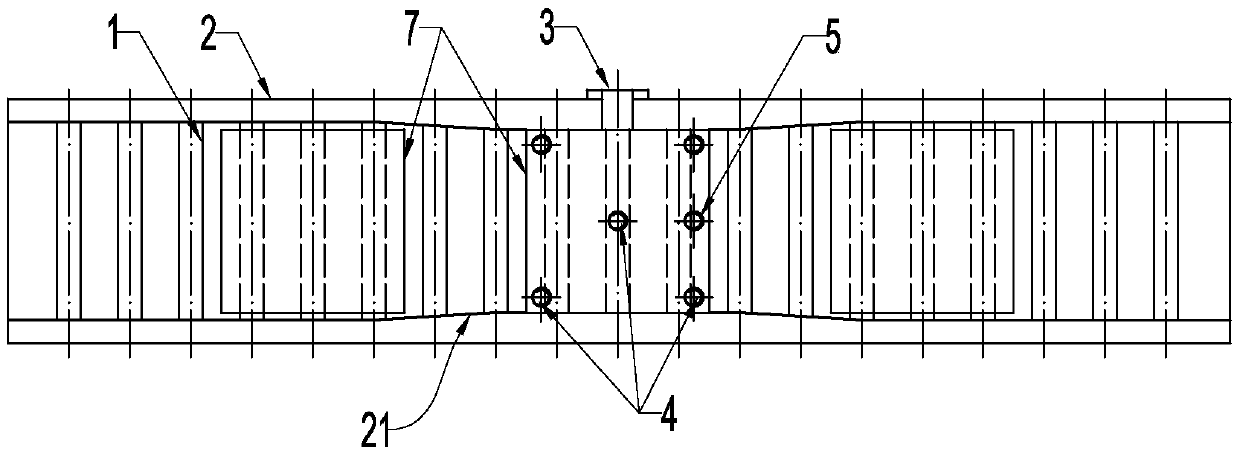

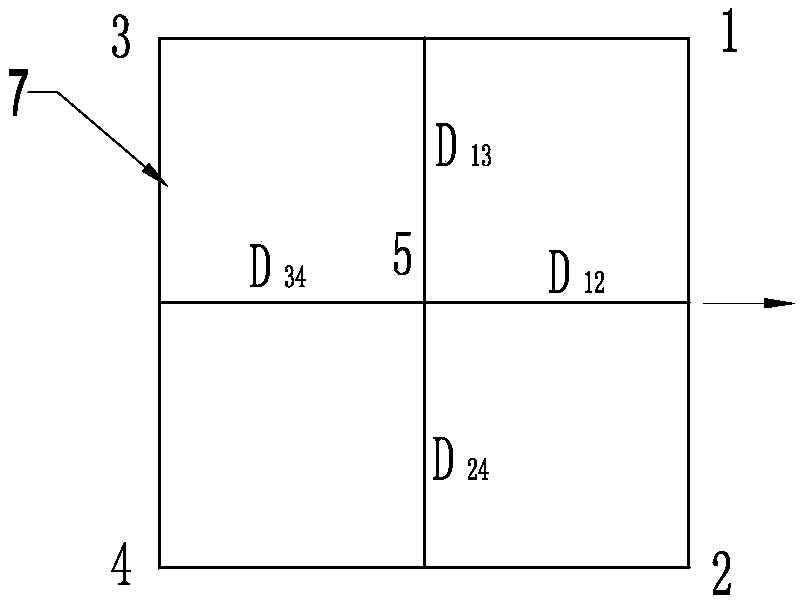

[0030] refer to figure 1 and figure 2 , ceramic tile flatness on-line detection method, comprises conveyor belt 1, conveyor belt frame 2, detection support 3, sensor 4, photoelectric switch 5 and computer 6; Detection support 3 is fixed on the conveyor belt frame 2, is set on this detection support 3 There is a detection plane 31 parallel to the conveyor belt 1, five non-contact sensors 4 are fixed on the detection plane 31, the sensors 4 are facing the conveyor belt 1, and the distance between the plurality of sensors 4 and the conveyor belt 1 is adjusted to be equal; A sensor 4 corresponds to the four corner points of the ceramic tile 7 and the center point positions, and detects the four corner points of the ceramic tile and the center point distance; the photoelectric switch 5 is arranged on the conveyor belt frame 2, once the ceramic tile 7 is delivered, The signal that photoelectric switch 5 outputs controls sensor 4 collection action after computer 6, and sensor 4 syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com