Feeding mechanism with holes punched on surface

A feeding mechanism and punching technology, applied in the field of punching feeding mechanism and surface punching feeding mechanism, can solve the problems of increasing the manufacturing cost of parts, low precision and high cost, and achieve the effect of increasing the manufacturing cost and prolonging the manufacturing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

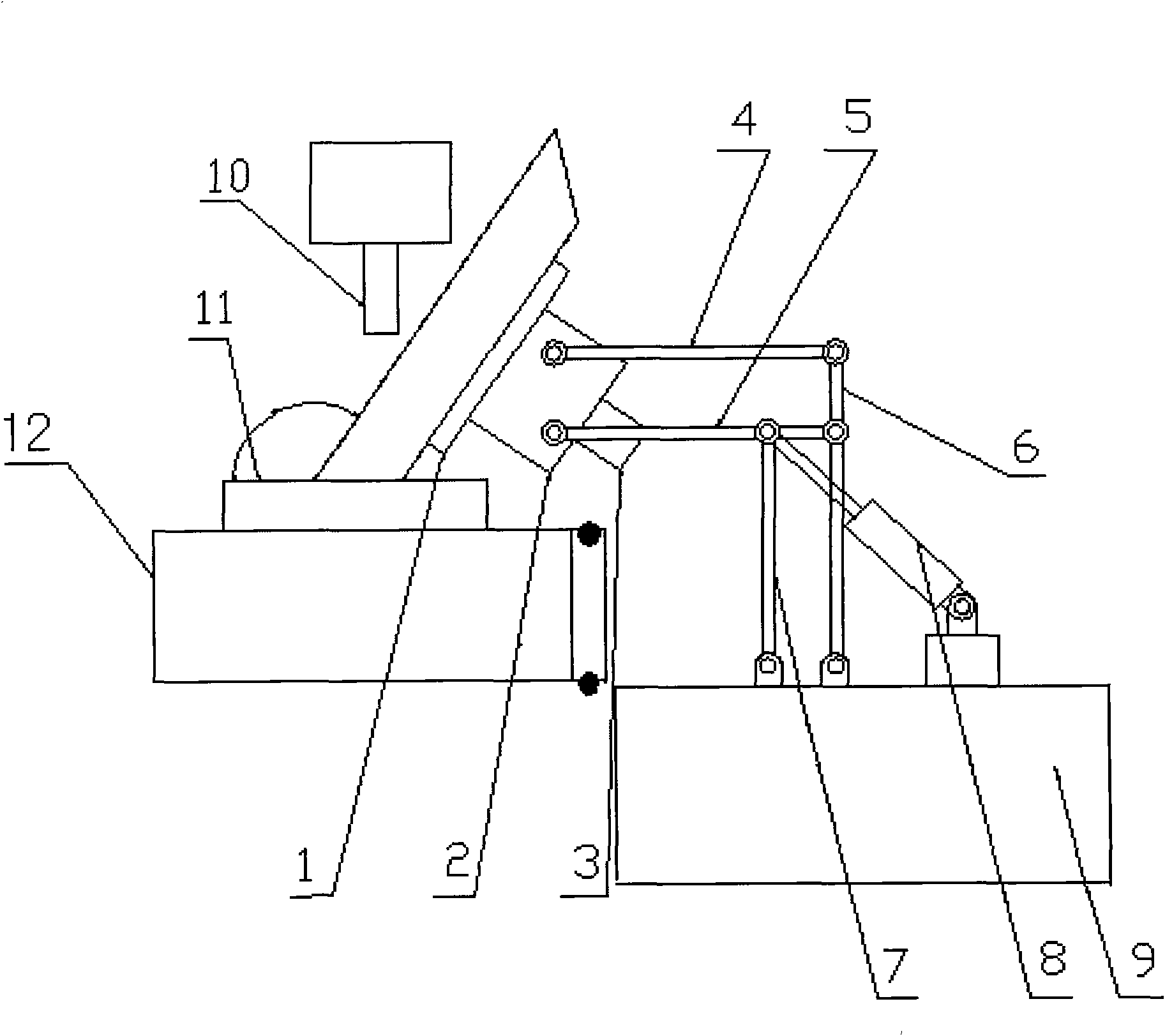

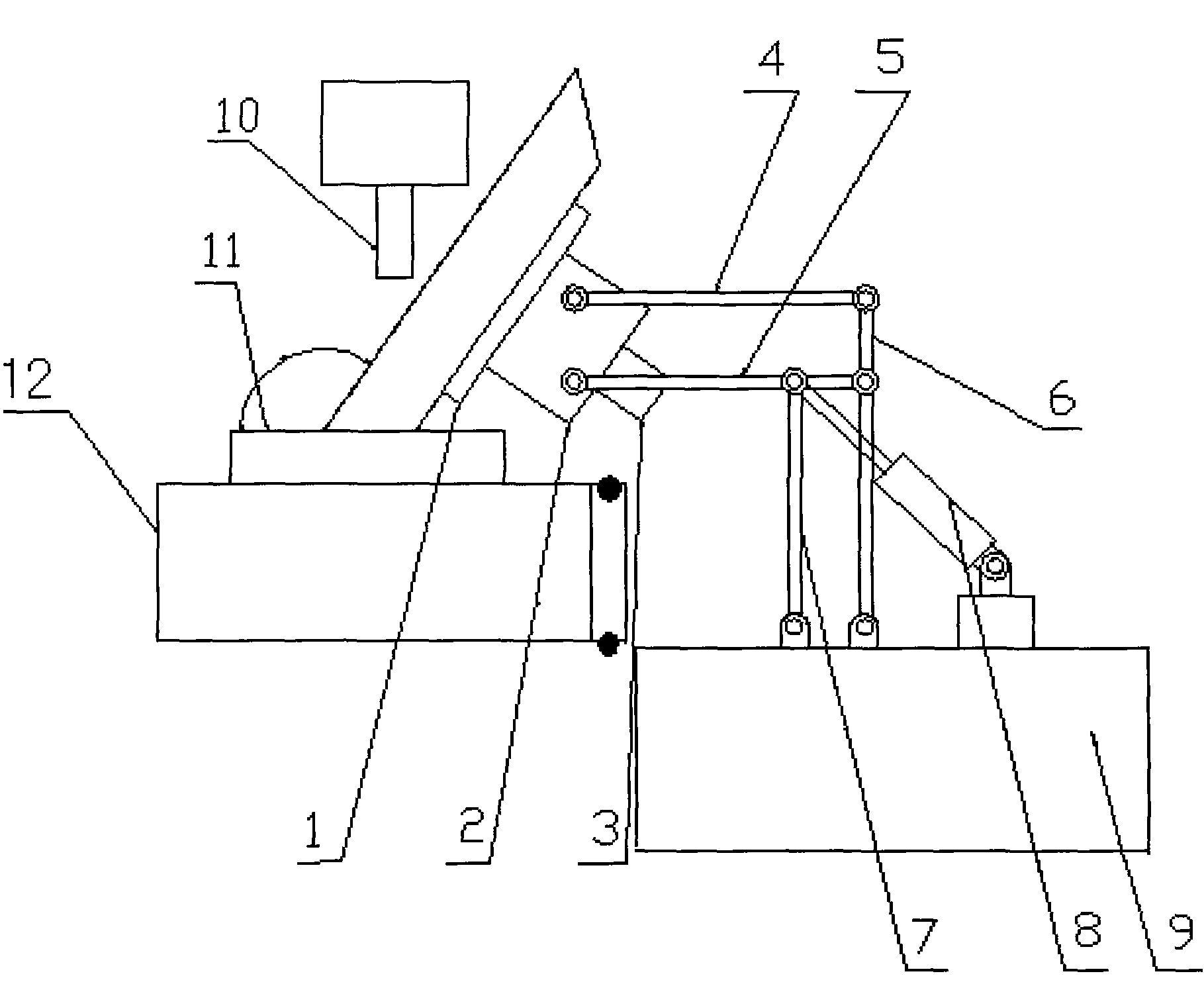

[0008] Hinge the connecting rod (4) a, connecting rod (5) b, connecting rod (6) c, and connecting rod (7) d at the corresponding positions with pins according to the correct requirements. 1), speed reducer (2), stepper motor (3) form a unified integral body hinged on one end of connecting rod (4) a, connecting rod (5) b, and connecting rod (6) c, connecting rod (7) ) d the other end is hinged on the fixed platform, the above-mentioned parts form a parallelogram luffing mechanism, and at the same time, each hinged joint is guaranteed to rotate flexibly, and finally, the piston cylinder of the cylinder (8) and the above-mentioned parts form a parallelogram luffing mechanism One of the joints in the middle is hinged, and is integrally hinged with the fixed table (9), upper mold (10), lower mold (11), and lower mold body (12), thereby realizing surface punching of various specifications.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com