Spinning machine with thread suction device

A technology of spinning machine and equipment, applied in the field of spinning machine, can solve problems such as disconnection and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

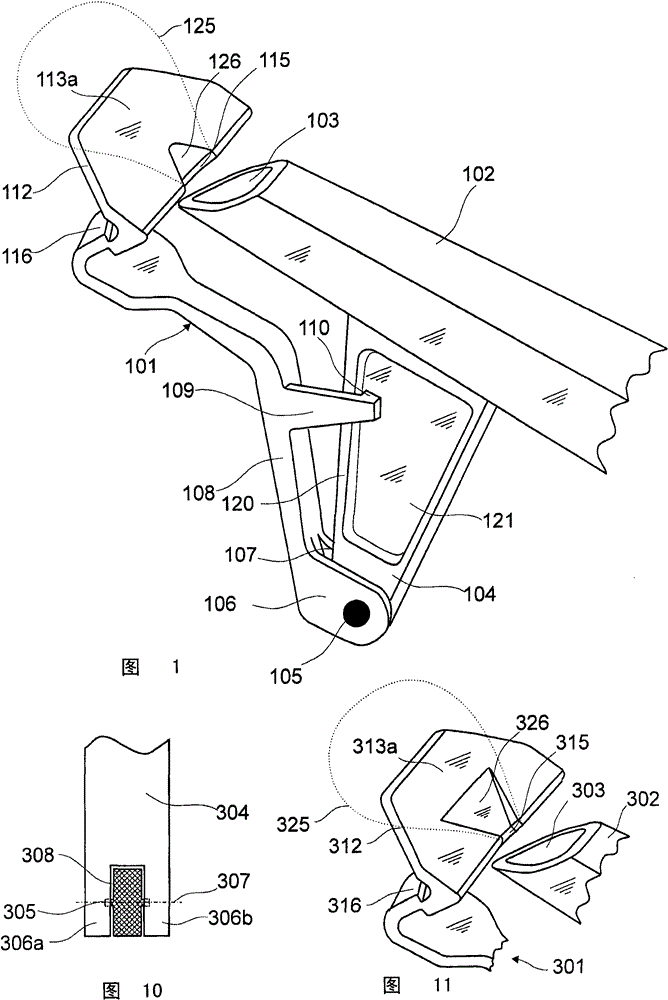

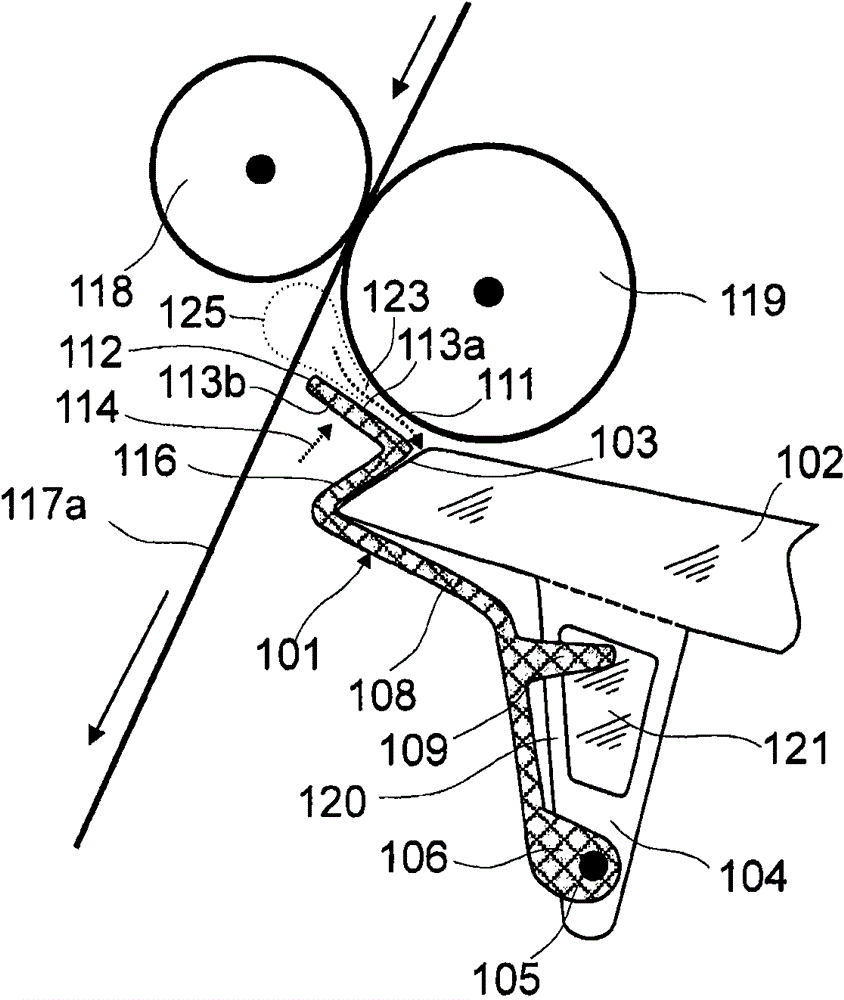

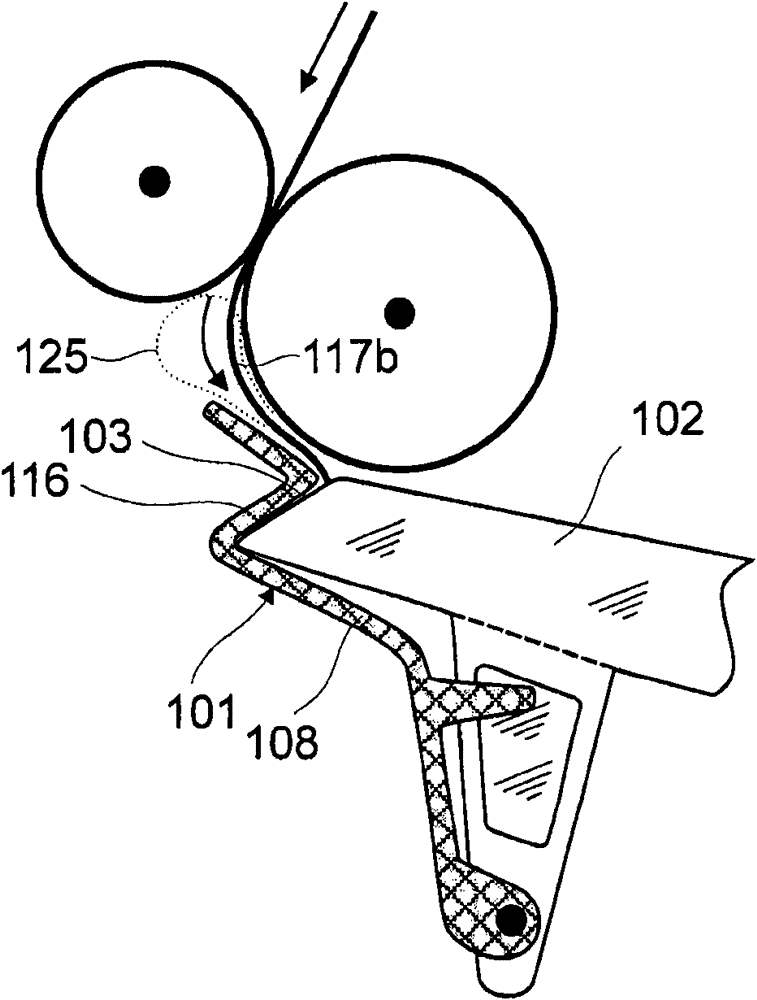

[0070] figure 1 and Fig. 2 shows a first embodiment of a first variant of the invention, Figure 7 A second embodiment is shown. image 3 and Figure 4 shows a first embodiment of the second variant of the invention, Figure 5 with Image 6 A second embodiment is shown. Figure 8 with Figure 9 Another embodiment of the first and third variants of the invention is shown.

[0071] according to figure 1 , 3 The suction pipe 2, 102, 202 of and 8 includes a tongue-shaped part 4, 104, 204 integrally formed with the pipe, and the closing part 1, 101, 201 is connected to the tongue-shaped part integrally formed with the pipe through a swivel joint 5, 105, 205 part. The swivel joint 5 , 105 , 205 consists of two tenons connected to the tongue-shaped part 4 , 104 , 204 integrally formed with the tube and guided through two tabs 6 on the closing part 1 , 101 , 201 , 106, 206; 7, 107, 207 holes or recesses, two tabs 6, 106, 206; Of course, the tenon could also be provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com