A kind of conductive paste and its preparation method and application, battery

A technology of conductive paste and conductive material, applied in conductive materials dispersed in non-conductive inorganic materials, battery electrodes, secondary batteries, etc., can solve problems such as battery performance degradation, and achieve the effect of alleviating specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

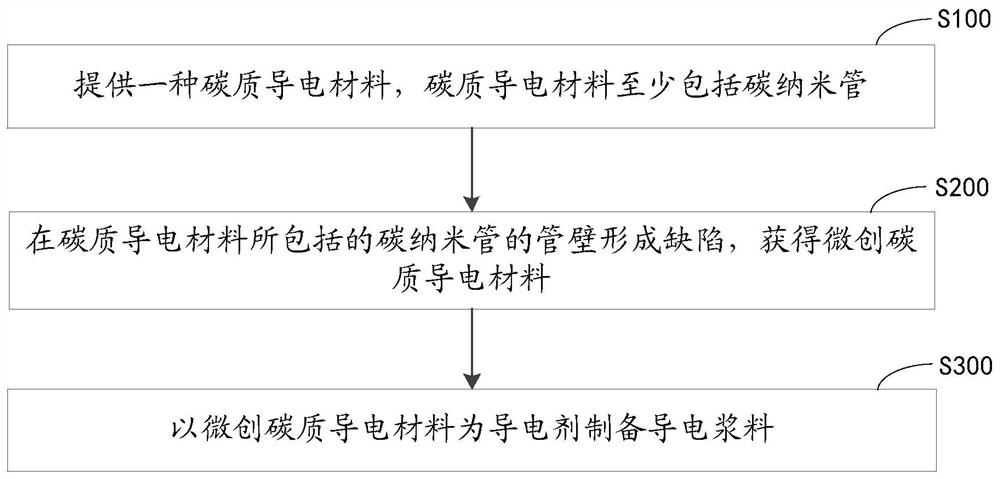

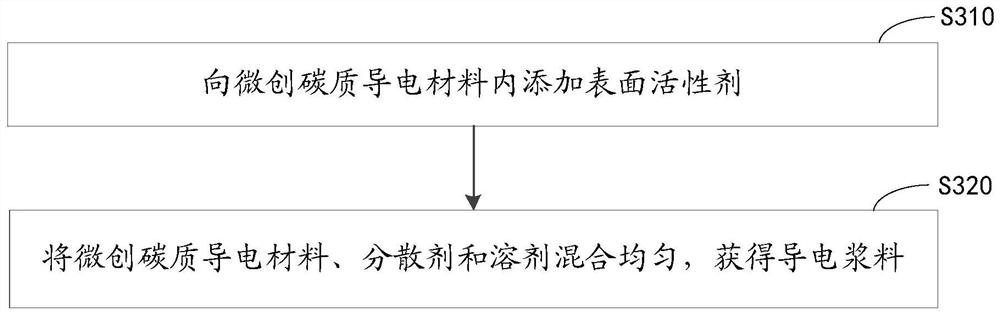

[0025] The embodiment of the present invention provides a kind of preparation method of conductive paste, such as figure 1 Shown, the preparation method of this conductive paste comprises:

[0026] Step S100: providing a carbonaceous conductive material, the carbonaceous conductive material at least includes carbon nanotubes. The size of carbon nanotubes can be adjusted according to actual conditions. For example: in order to improve battery performance, the purity of carbon nanotubes is greater than 98.5%, the diameter of carbon nanotubes ranges from 5nm to 15nm, and the specific surface area of carbon nanotubes is greater than 260m 2 / g. At this time, the carbon nanotubes have a small diameter, high purity and high specific surface area. When the conductive paste prepared from the carbonaceous conductive material including the carbon nanotubes is used in a battery, the energy density and rate performance of the battery can be fully improved. and cycle life performance. ...

Embodiment 1

[0064] The preparation method of the conductive paste provided by the embodiment of the present invention comprises the following steps:

[0065] Step S100: Provide a carbonaceous conductive material, the carbonaceous conductive material only includes carbon nanotubes; the purity of the carbon nanotubes is 99%, the tube diameter is 5nm, and the specific surface area is 270m 2 / g.

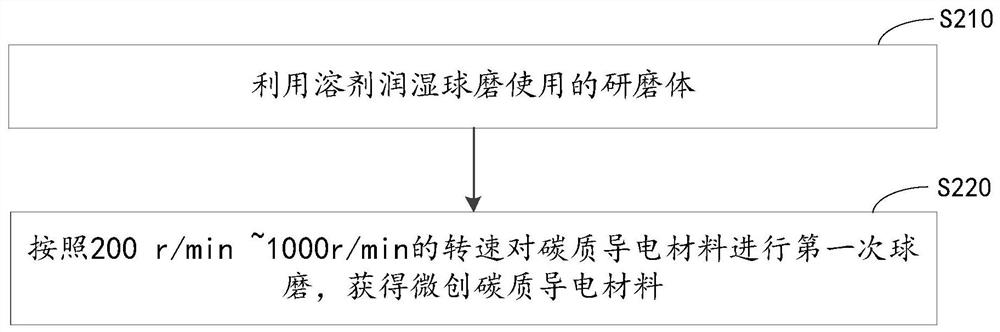

[0066] Step S200: forming defects on the tube wall of the carbon nanotubes included in the carbonaceous conductive material to obtain a minimally invasive carbonaceous conductive material; specifically including:

[0067] Step S210: Wetting the zirconium beads used in the tank ball mill with deionized water.

[0068] Step S220: Add 2kg of zirconium beads into a 2L pot-type ball mill, the diameter of the zirconium beads is between 1mm and 5mm; then ball mill 20g of carbonaceous conductive material at a speed of 1000r / min for 5min to obtain a minimally invasive carbonaceous conductive material. Mate...

Embodiment 2

[0075] The preparation method of the conductive paste provided by the embodiment of the present invention comprises the following steps:

[0076] Step S100: Provide a carbonaceous conductive material, the carbonaceous conductive material is a mixture of carbon nanotubes: conductive carbon black with a mass ratio of 3:2; wherein, the purity of the carbon nanotubes is 98.8%, the diameter is 15nm, and the specific surface area 285m 2 / g.

[0077] Step S200: forming defects on the tube wall of the carbon nanotubes included in the carbonaceous conductive material to obtain a minimally invasive carbonaceous conductive material; specifically including:

[0078] Step S210: Wetting the zirconium beads used in the pot ball mill with N-methylpyrrolidone.

[0079] Step S220: Add 2kg of zirconium beads into a 2L pot-type ball mill, the diameter of the zirconium beads is between 1mm and 5mm; then ball mill 300g of carbonaceous conductive material at a speed of 300r / min for 30min to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com