Load control system

A technology of load control system and control unit, applied in transmission systems, digital transmission systems, telemetry/remote control selection devices, etc., can solve problems such as prolonging time and increasing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

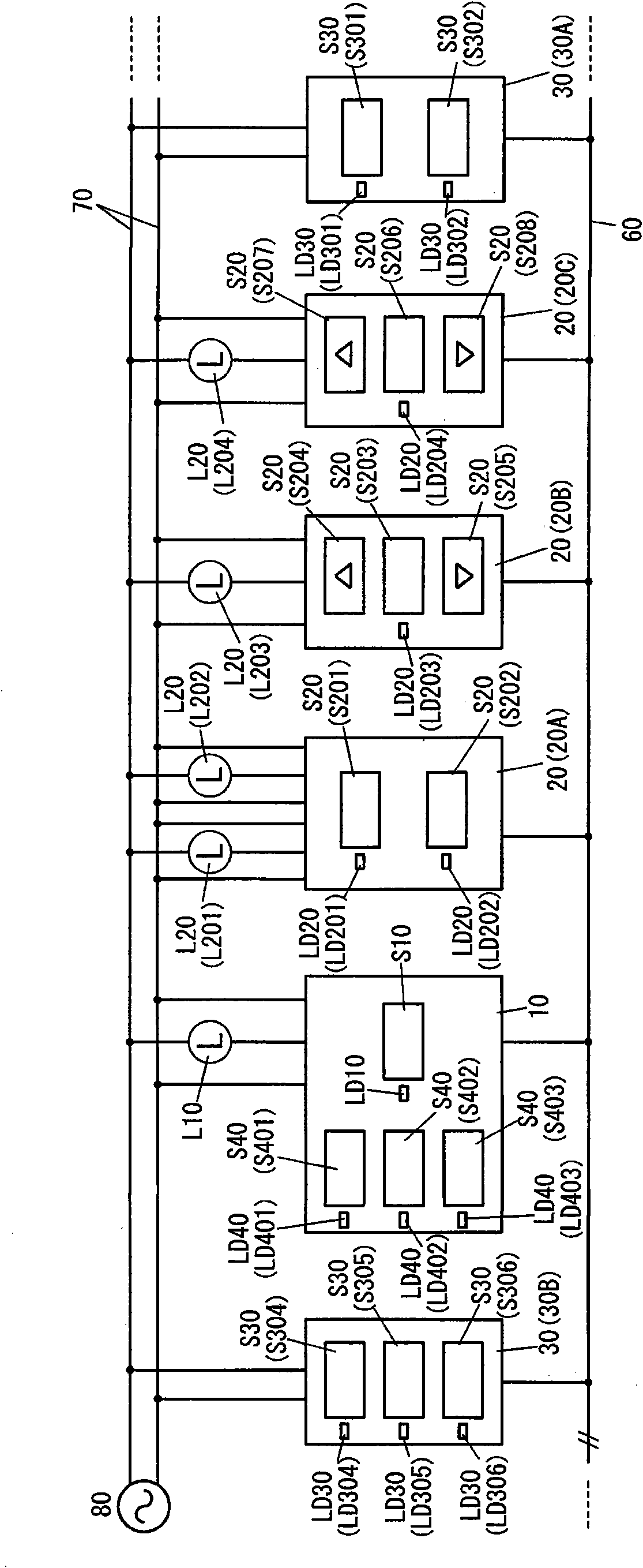

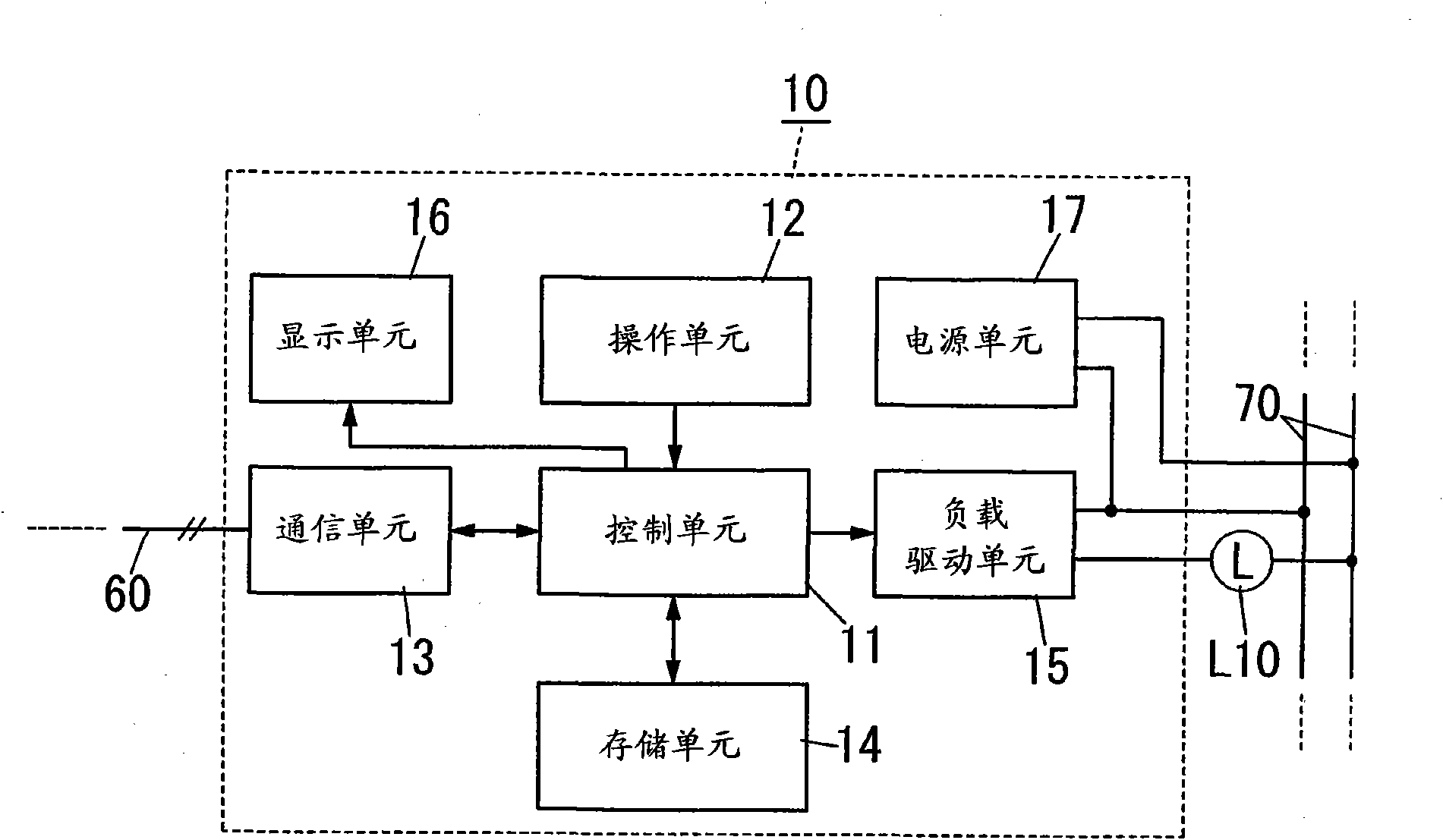

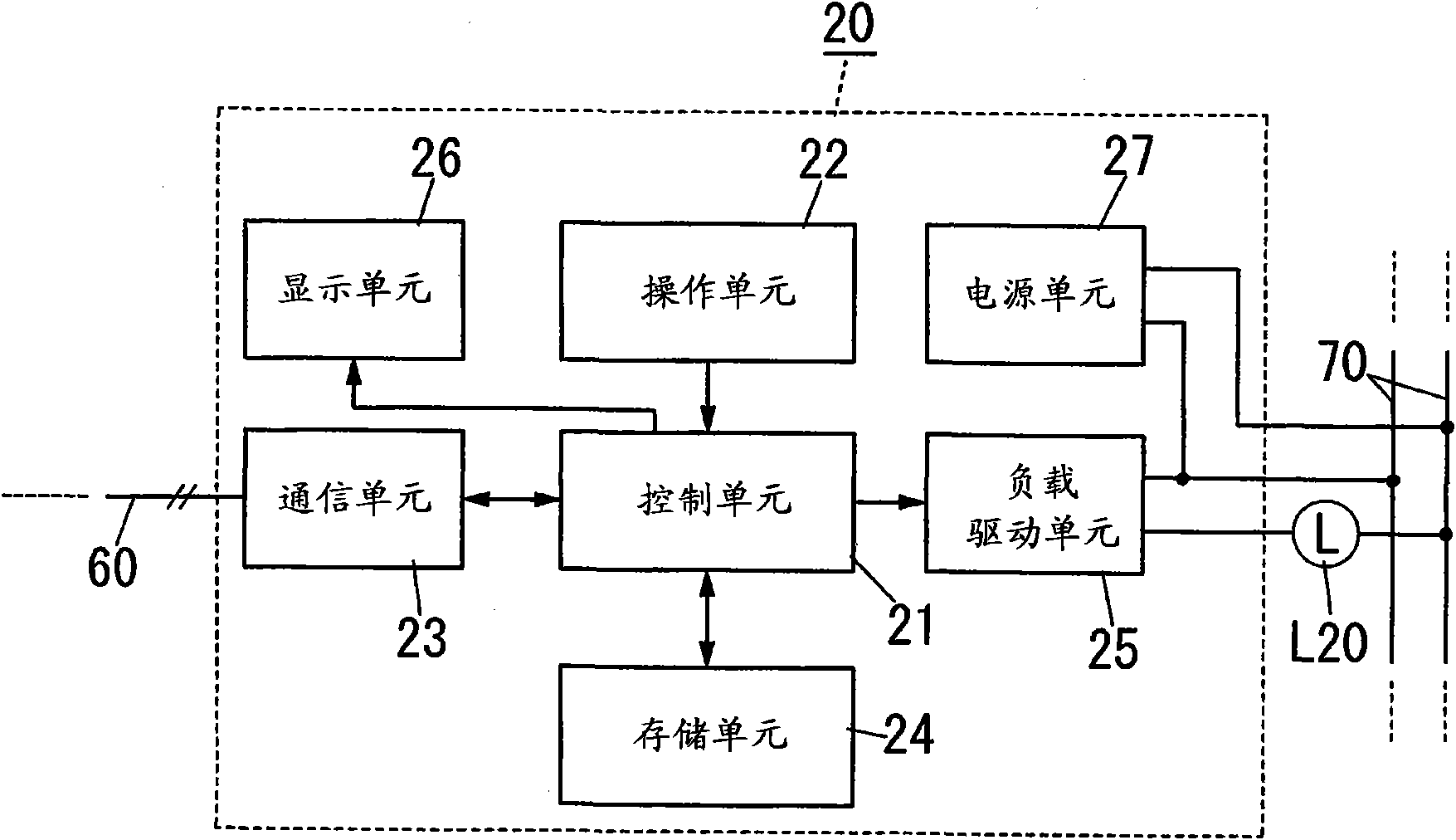

[0026] Now, refer to figure 1 , shows a load control system according to a preferred embodiment of the present invention. The load control system is suitable for controlling a plurality of loads L. This load control system has a first terminal (first operation control terminal) 10, a plurality of second terminals (second operation control terminals) 20 (20A, 20B, and 20C), and a plurality of third terminals (operation terminals) 30 ( 30A and 30B). The terminals 10 , 20 and 30 are connected to each other by a two-wire signal line 60 .

[0027] The load L includes a first load L10 and a plurality of second loads L20 ( L201 , L202 , L203 and L204 ). The first load L10 is connected to the first terminal 10 . Second loads L201 and L202 are connected to the second terminal 20A. The second loads L203 and L204 are connected to the second terminals 20B and 20C, respectively.

[0028] For example, each of loads L10 and L20 is a lighting load. Loads L10 and L20 are connected to an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com