Blanking and taking method of webs after automatic transverse cutting and die cutting

An automatic, cross-cutting technology, applied in metal processing and other directions, can solve the problems of incomplete cutting, inability to cut, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

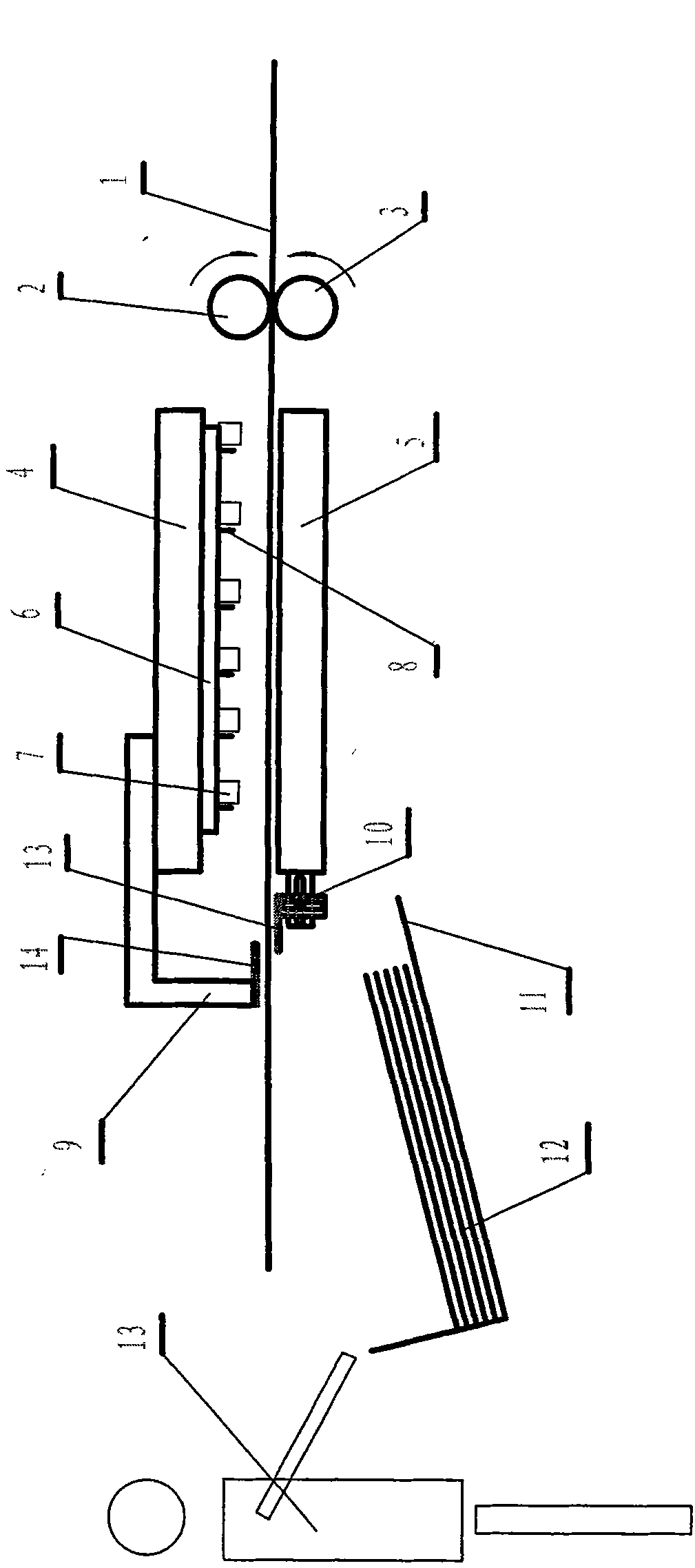

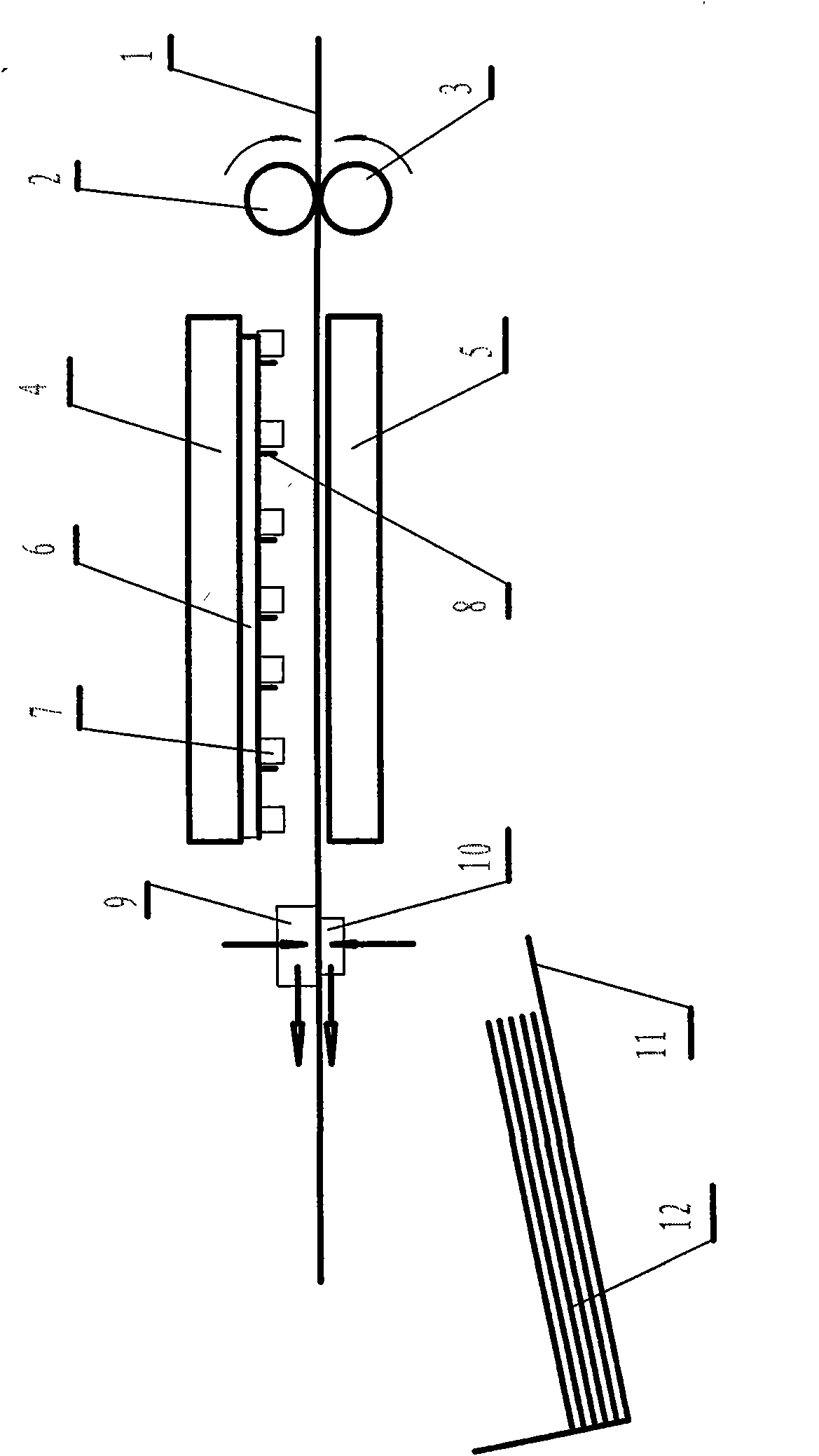

[0013] Embodiment 1: the method of circular motion+circular motion

[0014] like Figure 4 After the cross-cut die-cut material is sent to the material cutting station, the pressing member (9) which is driven by the rotating rod (13) and moves in a circular motion presses the material on the rotatable supporting member (10), And drive it to rotate to tear off the parts that need to be cut off. At the same time, it brings a movement speed to the finished product, so that the finished product flies into the hopper at high speed. The positions of the pressing (9) and the supporting member (10) are all adjustable, so that the required breaking force can be obtained by adjusting the pressing force.

Embodiment 2

[0015] Embodiment 2: the method of curvilinear motion+circle motion

[0016] like Figure 5 , using a multi-link transmission mechanism to drive the pressing part (9) to move on a curved track, the pressing part (9) can also press the material on the rotatable supporting part (10) during the movement, and drive it to rotate Pull off the part where the material needs to be broken. At the same time, it brings a movement speed to the finished product, so that the finished product flies into the hopper at high speed. Although this scheme is image 3 The scheme is more complicated, but it can reduce the movement space required by the pressing part (9), and can easily adjust the motion trajectory and speed of the pressing part (9), so as to achieve the best effect in actual use.

Embodiment 3

[0017] Embodiment 3: the method of rectilinear motion+circle motion

[0018] like Image 6 , driven by the die-cutting plate A (4), the pressing member (9) moving linearly compresses the material on the rotatable supporting member (10), and drives it to rotate to break the part where the material needs to be disconnected. After the pressing part (9) returns, the finished product automatically falls into the hopper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com