Method for producing ruthenium complex

A manufacturing method and technology of ruthenium complexes, which are applied in chemical instruments and methods, compounds containing elements of Group 8/9/10/18 of the periodic table, organic chemistry, etc., can solve the problems of limited application and high price, etc. To achieve the effect of optimizing reaction temperature, reducing the amount of production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0074] In the following descriptions, including the figures, "dcbpy" or "L" indicates the term 2,2'-bipyridyl-4,4'-dicarboxylic acid (2,2'-bipyridyl-4,4'- dicarboxylic acid) or 4,4'-dicarboxy-2,2'-bipyridine (4,4'-dicarboxyl-2,2'-bipyridine) ligand.

[0075] First, an overview of the one-pot method according to an embodiment of the present invention and a comparison between the one-pot method and a synthesis method based on a known method will be described.

[0076] (Ru(dcbpy) based on the one-pot method 2 (NCS) 2 comparison of the synthesis based on known methods)

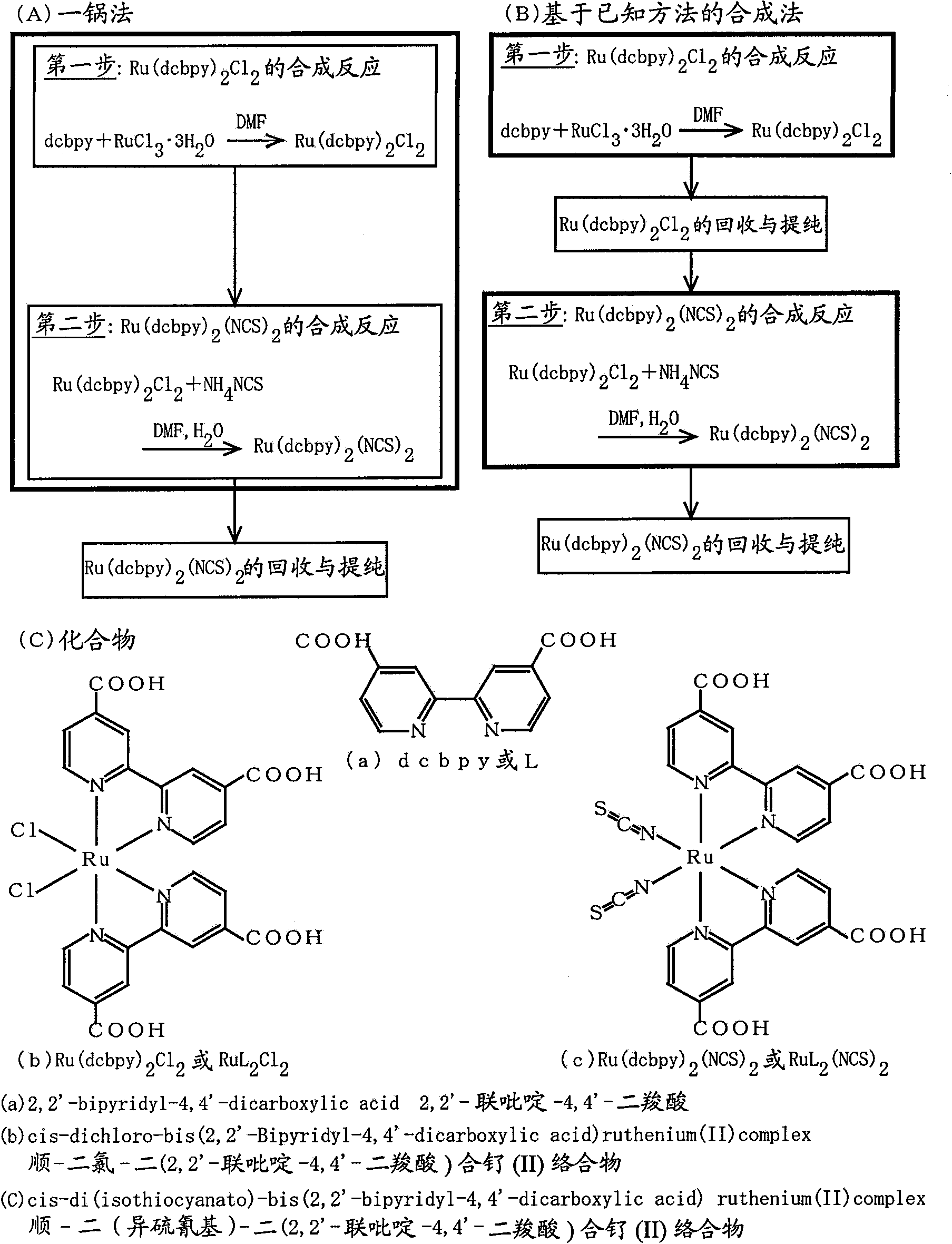

[0077] figure 1 It is to compare the difference between the one-pot method in the embodiment of the present invention and the known synthetic method, figure 1 (A) is a one-pot method, while figure 1 (B) is an explanation for known law, figure 1 (C) shows the structures of the compounds involved in the reaction.

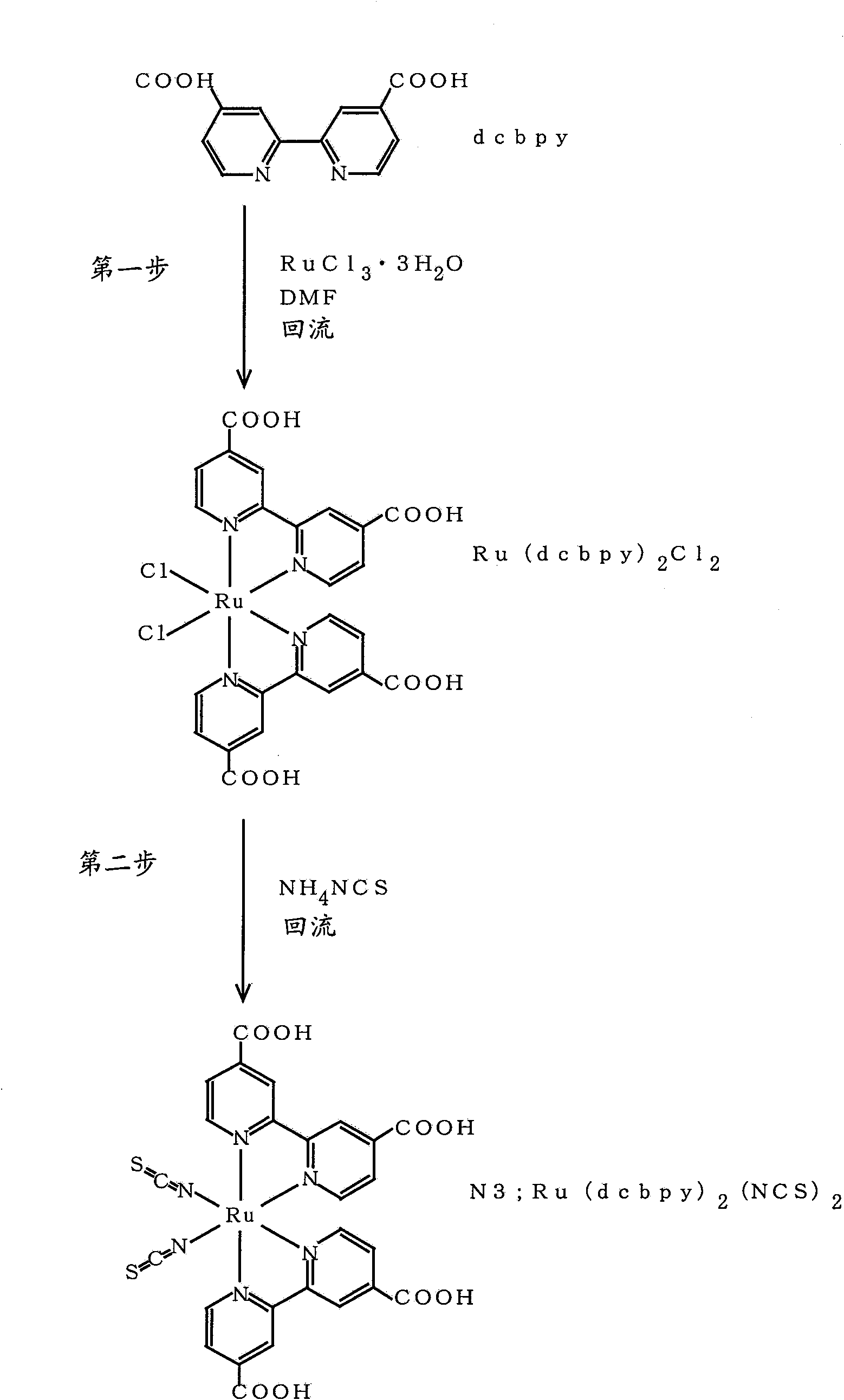

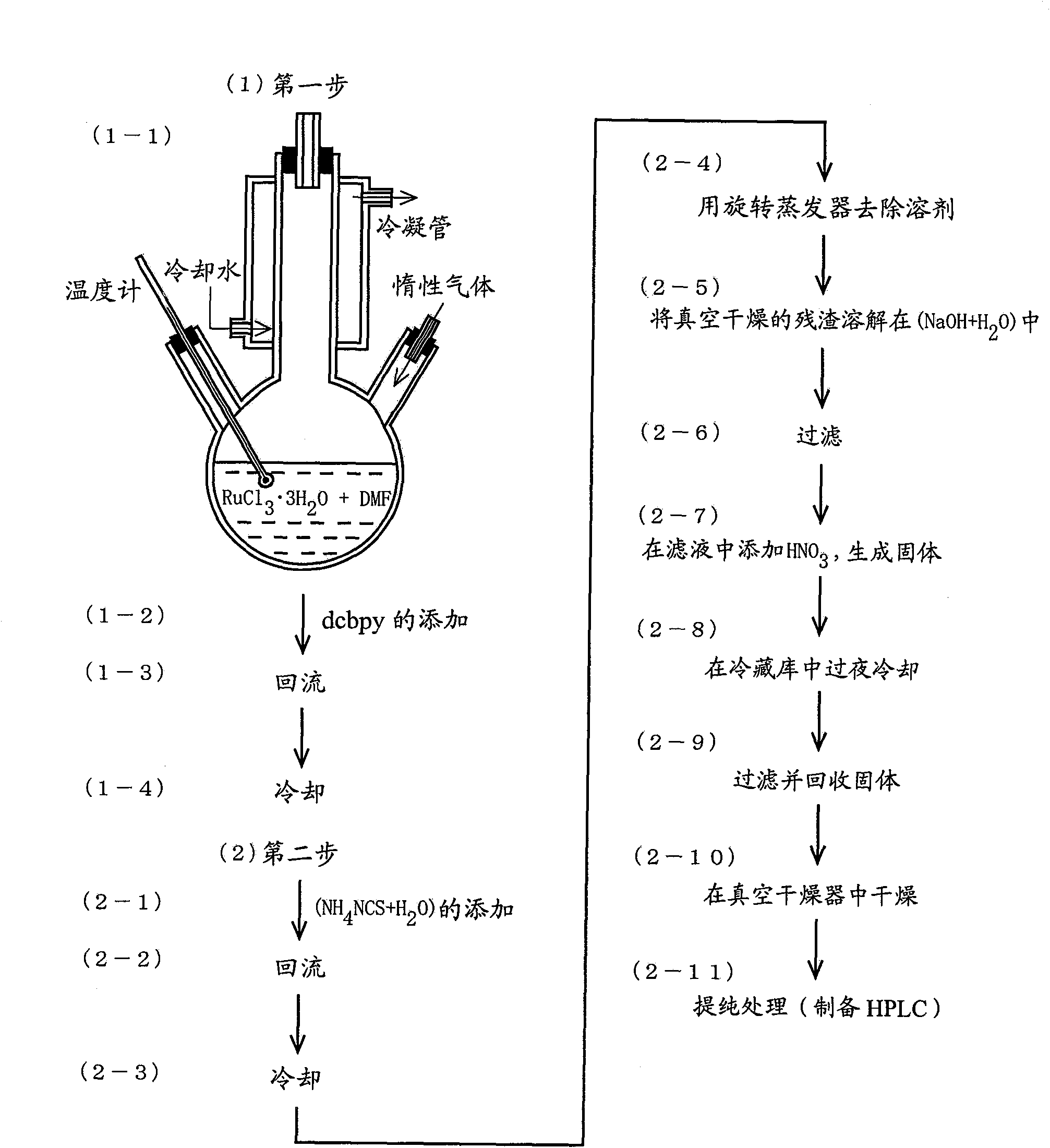

[0078] figure 2 is a synthetic procedure illustrating a one-pot method in an embodiment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com