Charge and discharge method for container formation of green accumulator plates and container formation technique

A technology for raw plates and storage batteries, which is applied in the field of internal formation of battery raw plates, can solve the problems of long formation time and high energy consumption, and achieve the effects of short formation time, elimination of polarization voltage, and fast charging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

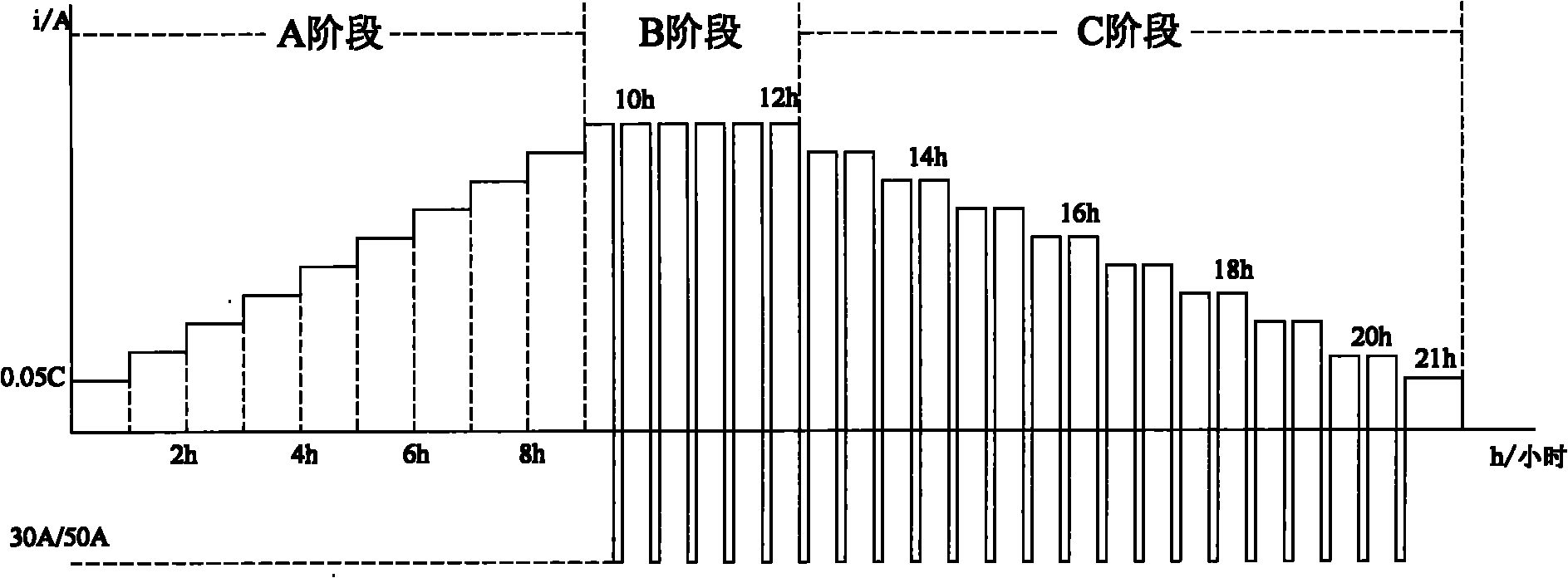

[0052] Please refer to figure 1 , figure 1 The schematic diagram of the charge-discharge program curve for internalization of raw plates provided for the specific implementation of the present invention, taking a 12V100Ah storage battery as an example:

[0053] When the ambient temperature is higher than 10°C to 30°C, the charging power MC is 3.0C, and the charging time in stage A is t 1 Take 9h, the charging time of stage B is t 2 Taking 3h, the charging time of stage C is 9h, the total charging time is 21h, and the charging current NC of stage A is 0.05C, that is, 0.05×100=5A, then

[0054] 21×0.05C+2×(x+2x+3x+4x+5x+6x+7x+8x)+3×9x=3C

[0055] Get x=0.02C=2A,

[0056] Then the charging procedure formed in the storage battery is:

[0057] charging time

[0058] At the same time, from the 10.5h to the 21st hour, discharge for 1 minute every 0.5h.

Embodiment 2

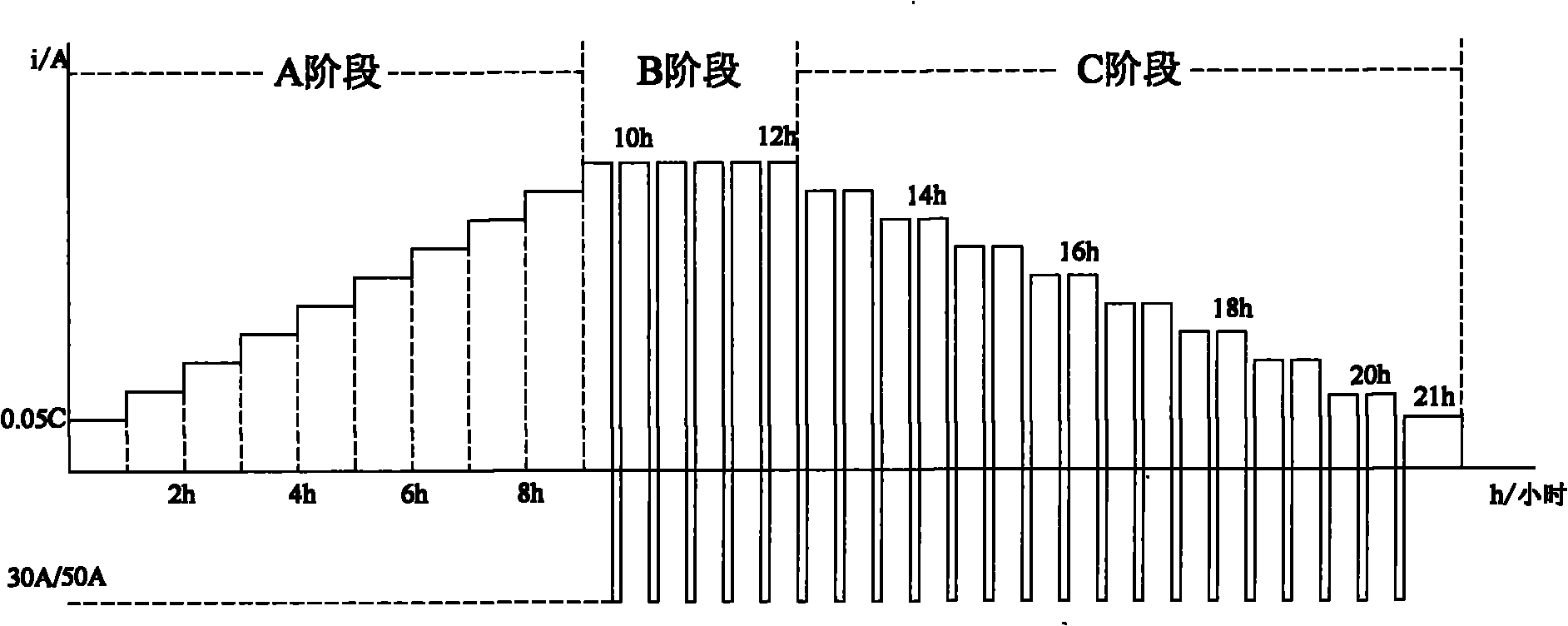

[0060] Take the 12V100Ah battery as an example:

[0061] When the ambient temperature is lower than 10°C to below 0°C, the charging power MC is 3.5C, and the charging time in stage A is t 1 Take 9h, the charging time of stage B is t 2 Taking 3h, the charging time of stage C is 9h, the total charging time is 21h, and the charging current NC of stage A is 0.05C, that is, 0.05×100=5A, then

[0062] 21×0.05C+2×(x+2x+3x+4x+5x+6x+7x+8x)+3×9x=3.5C

[0063] Get x=0.025C=2.5A,

[0064] Then the charging procedure formed in the storage battery is:

[0065] charging time

1h

2h

3rd hour

4h

5h

6h

7h

recharging current

5A

7.5A

10A

12.5A

15A

17.5A

20A

charging time

8h

9h

10h

11h

12h

13h

14h

recharging current

22.5A

25A

27.5A

27.5A

27.5A

25A

22.5A

charging time

15th hour

16h

17h

18h

19h

20h

21h

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com