Charge and discharge test equipment for full on-line storage battery pack

A charging and discharging test, battery pack technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of interruption accident, high risk, waste of energy, etc., to achieve flexible and safe use, wide range of use, and degree of intelligence high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

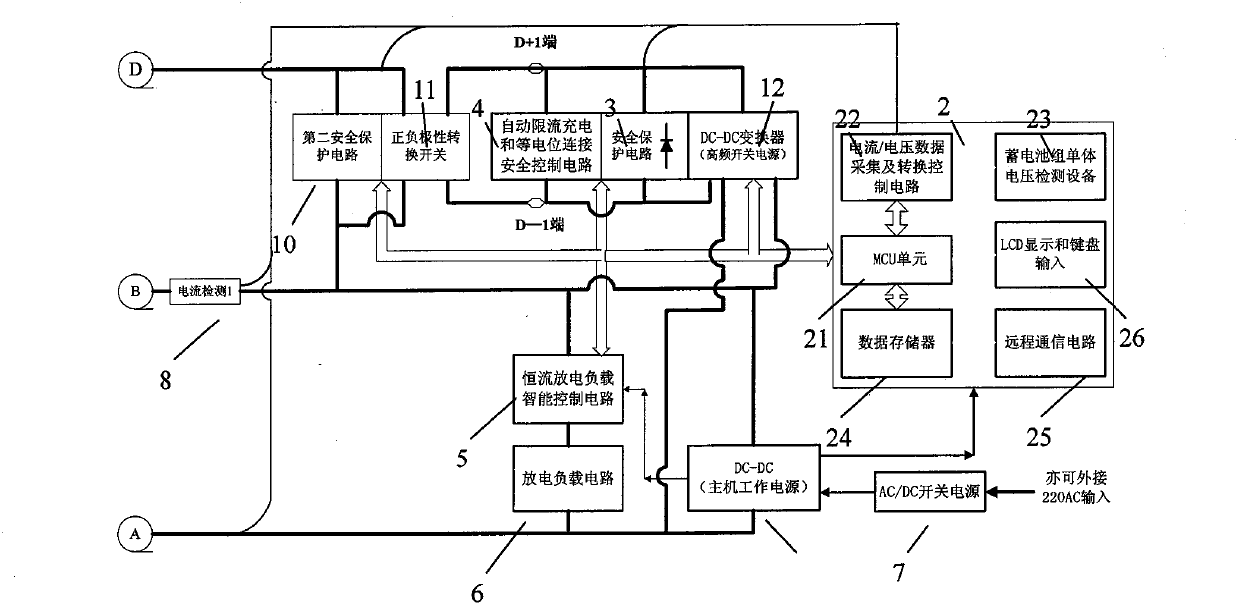

[0040] see figure 1 As shown, the full-line battery charge and discharge test equipment of this embodiment includes a DC-DC host power supply 1, a control unit 2, a safety protection circuit 3, and an automatic current-limiting charging and equipotential bonding safety control circuit 4 , a constant current discharge load intelligent control circuit 5, a discharge load circuit 6, a DC-DC converter 12, a positive and negative polarity conversion switch 11, a second safety protection circuit 10 and other circuit modules. The control unit 2 further includes an MCU unit 21, and a current / voltage data acquisition and conversion control circuit 22 connected to the MCU unit 21, a battery unit voltage detection device 23, a data memory 24, and a remote communication circuit. 25. LCD display and keyboard input 26.

[0041] The safety protection circuit 3 , the automatic current limiting charging and equipotential connection safety control circuit 4 , and the DC-DC converter 12 are con...

Embodiment 2

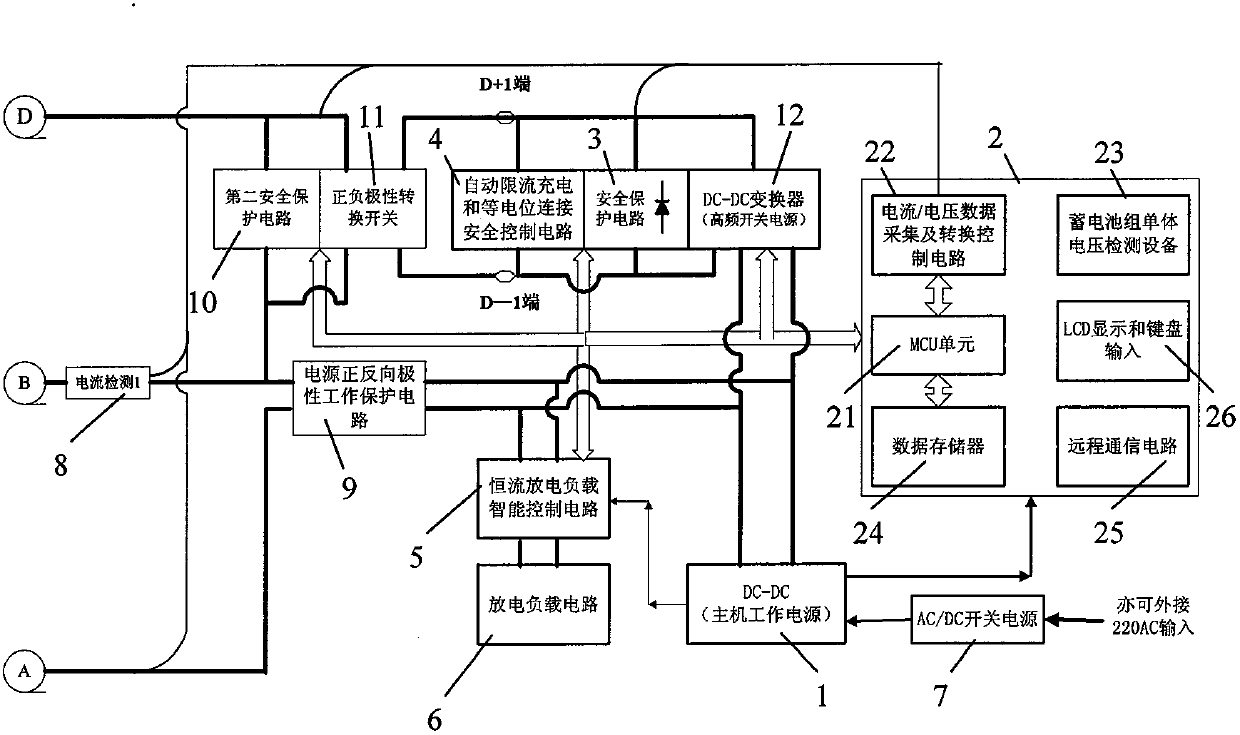

[0060] see figure 2 Compared with Embodiment 1, the difference between the second embodiment and the first embodiment is that the full-on-line storage battery charge and discharge test equipment in the second embodiment also includes a power supply forward and reverse polarity protection circuit 9, and the forward and reverse polarity of the power supply The output of the polarity work protection circuit 9 is connected in series with the constant current discharge load intelligent control circuit 5 and the discharge load circuit 6, and then connected in series to the DC-DC converter 12 and the DC-DC host operating power supply 1 connected in parallel. All the other structures are the same as in Embodiment 1.

[0061] Explanation: In the first embodiment, the DC-DC converter 12, the constant current discharge load intelligent control circuit 5, and the DC-DC host operating power supply 1 are distributed in the forward and reverse polarity protection circuit function of the inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com