Speed-regulating system for switched reluctance motor specially used for electric vehicle

A technology of switched reluctance motors and electric motors, which is applied in the direction of single motor speed/torque control, torque ripple control, etc. It can solve the problems of large operating current, large starting current, and few applications, so as to improve low-speed torque fluctuations problem, the effect of increased power density and wide speed range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

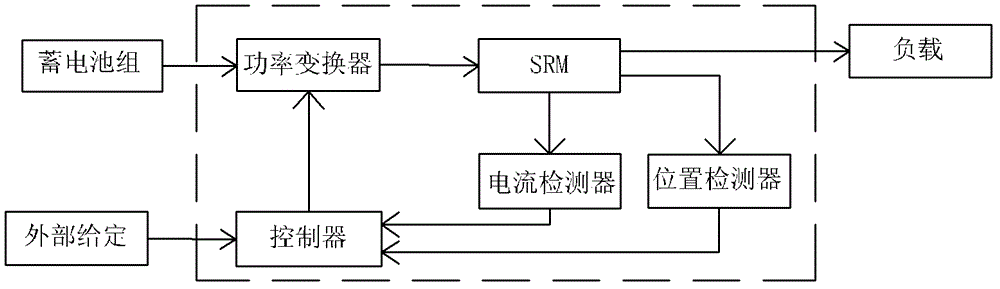

[0052] Such as figure 1 As shown, the system includes controller, power converter, motor and sensors.

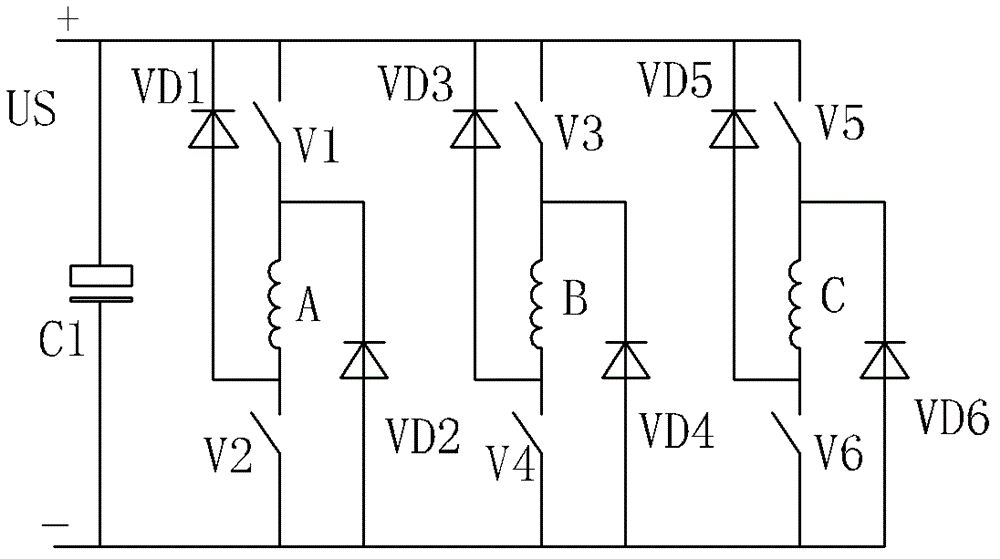

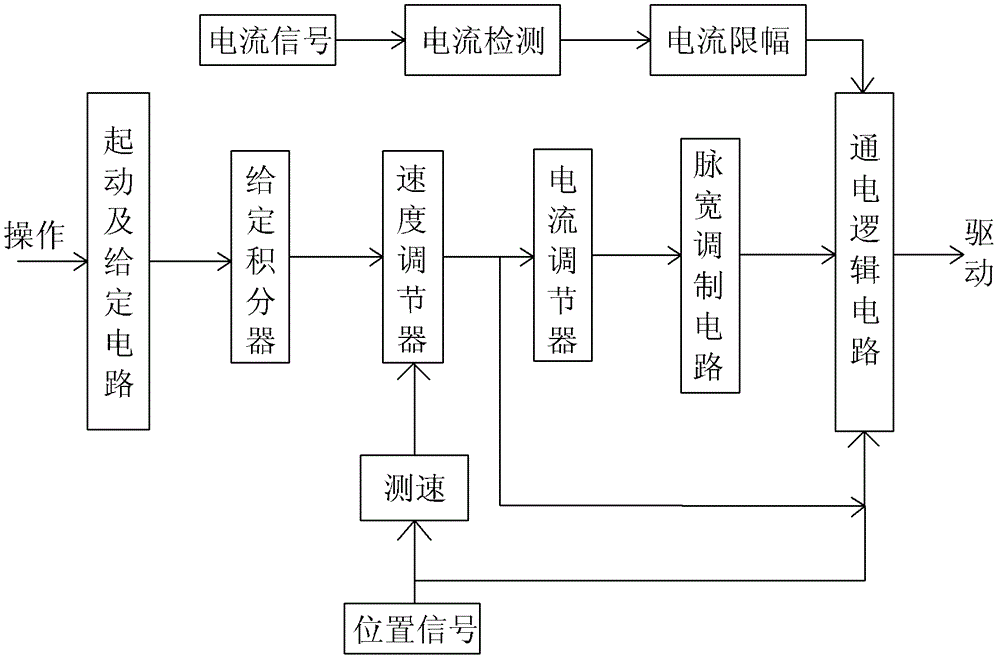

[0053] The output end of the controller is connected to the control end of the power converter to output control signals, and the input end of the controller is connected to an external setting; the output end of the power converter is connected to the motor, and its input end is connected to the battery pack; the motor is a switching magnetic Resistance motor, the number of stator / rotor poles of the switched reluctance motor is 24 / 16 poles, the output shaft of the switched reluctance motor is connected to the load; the sensor includes a current detector and a position detector, and the current detector is used to detect the operation of the switched reluctance motor The current and position detectors are arranged inside the switched reluctance motor to detect the relative position of the rotor and the stator and the speed signal, and the output terminals of the current dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com