Plasma etching chamber

A plasma and corrosion chamber technology, applied in the field of ion corrosion chamber, can solve the problems of gas distribution plate pollution and other problems, and achieve the effect of reducing the amount of residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the plasma etching chamber will be described in detail with reference to the accompanying drawings.

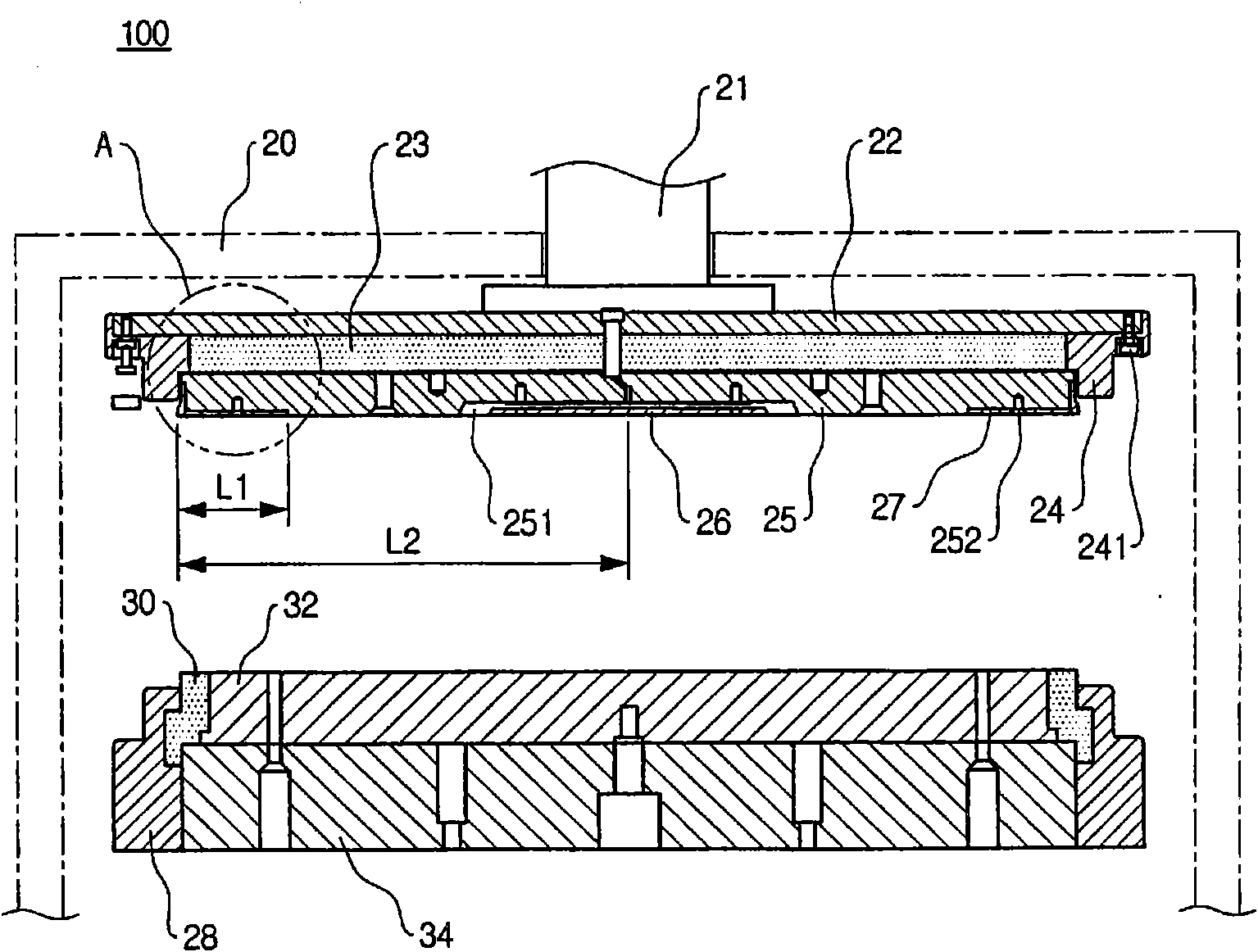

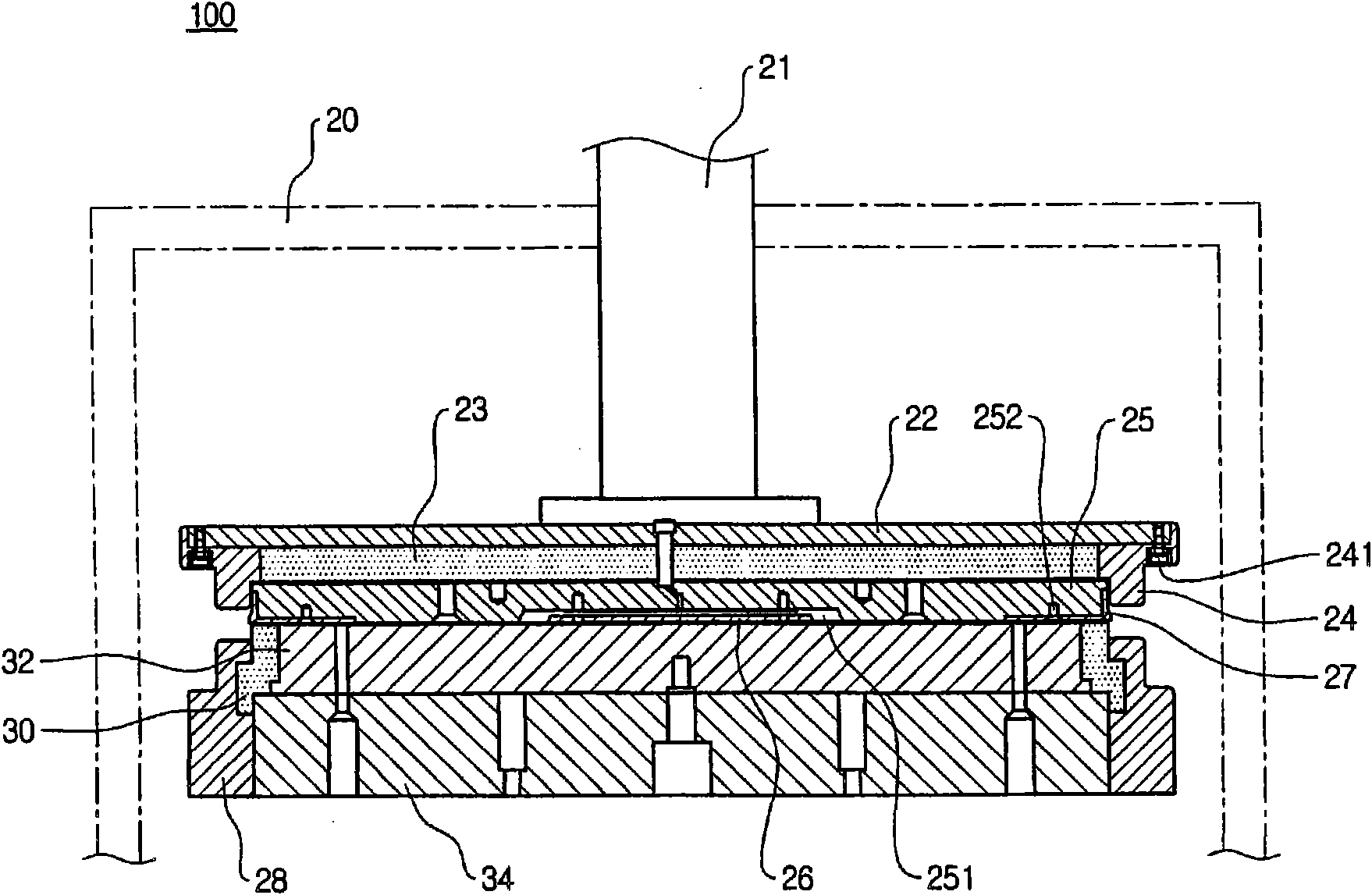

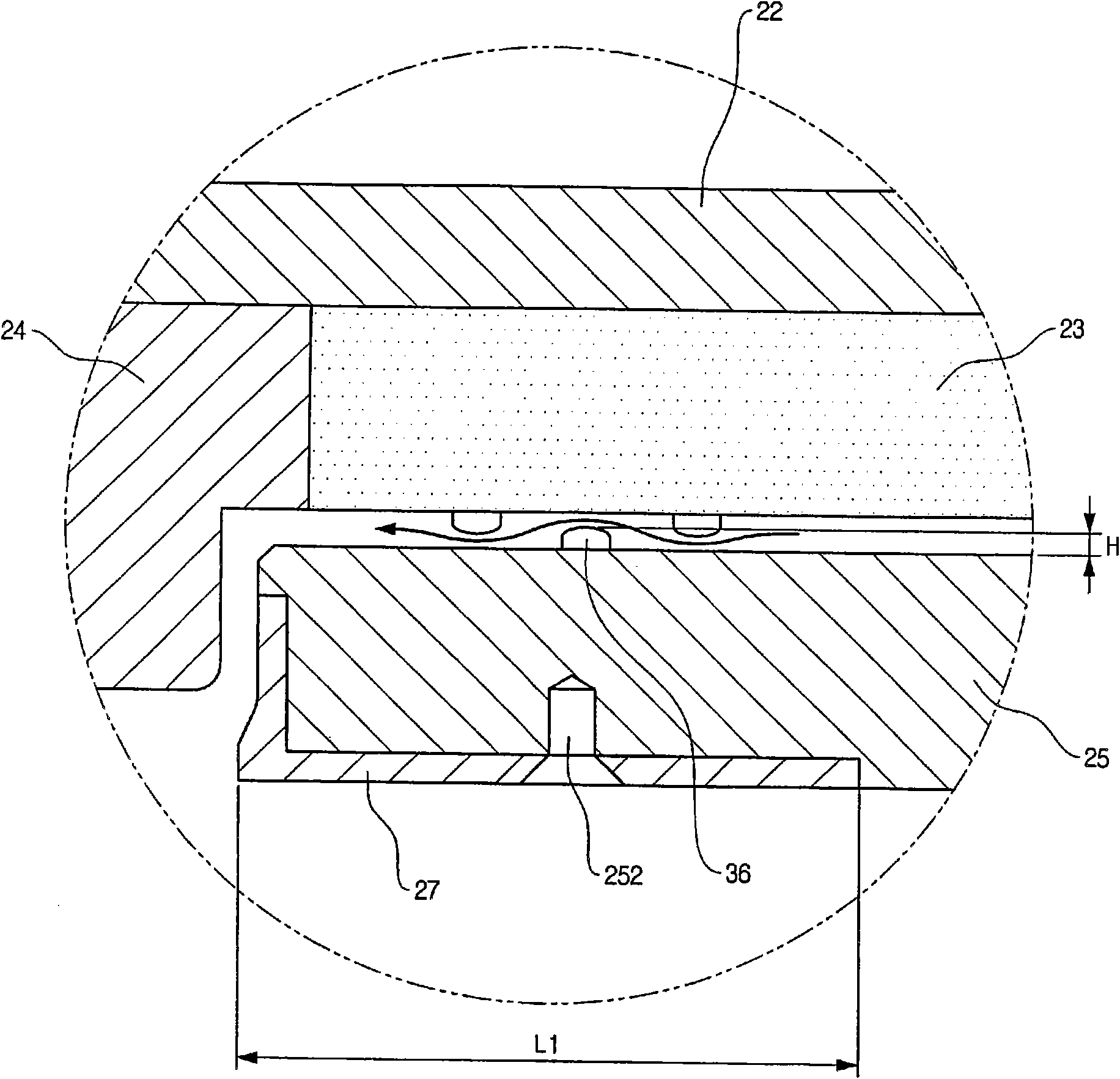

[0031] figure 1 is a partial cross-sectional view of the plasma etching chamber. figure 2 is a partial cross-sectional view of the plasma etch chamber after the moving rod is lowered. image 3 yes figure 1 Partial enlarged view of part A in the middle. Figure 4 is a schematic plan view of the gas distribution plate.

[0032] see figure 1 and 2 , the plasma etching chamber 100 includes a chamber wall 20 providing a space isolated from the outside thereof, a moving rod 21 operated by an actuator (not shown) when passing the upper part of the chamber wall 20, and a plate formed under the moving rod 21 . The plates include an upper plate 22 and a lower plate 23 .

[0033] The lower plate 23 is arranged under the bottom surface of the upper plate 22 , and the ring-shaped upper electrode 24 is arranged along the edge of the lower plate 23 . The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com