Packing box

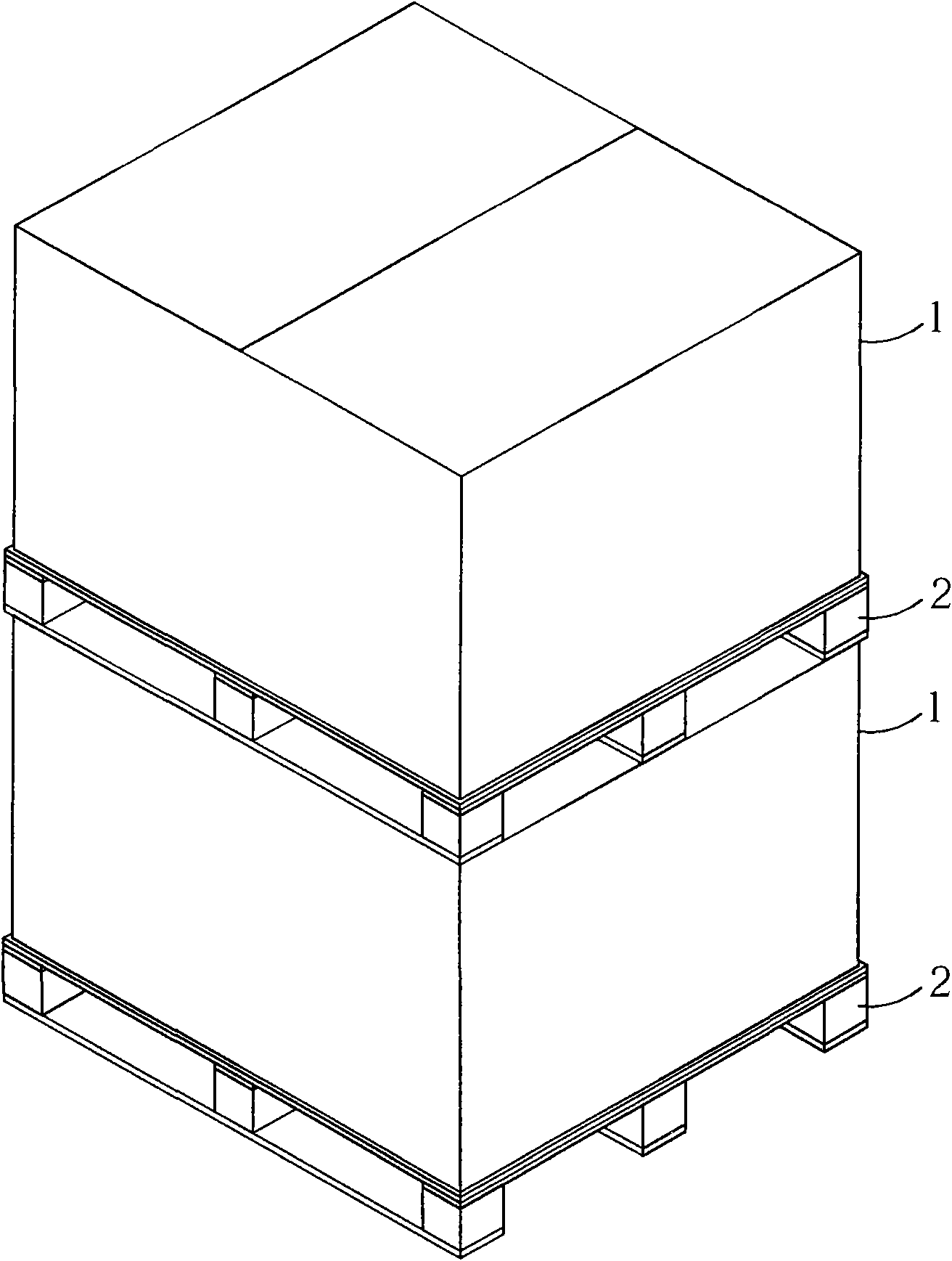

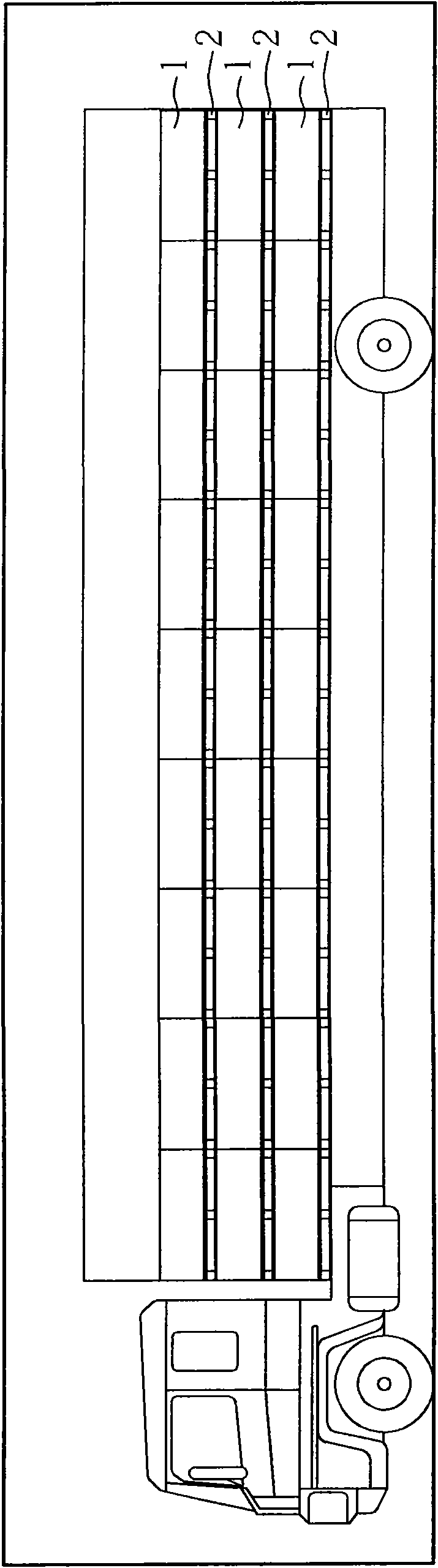

A technology for packaging boxes and boxes, applied in the directions of packaging, transportation and packaging, rigid containers, etc., can solve the problems of reducing loading, increasing transportation and pallet costs, space waste, etc., to increase loading, reduce transportation and stacking. The effect of the board fee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

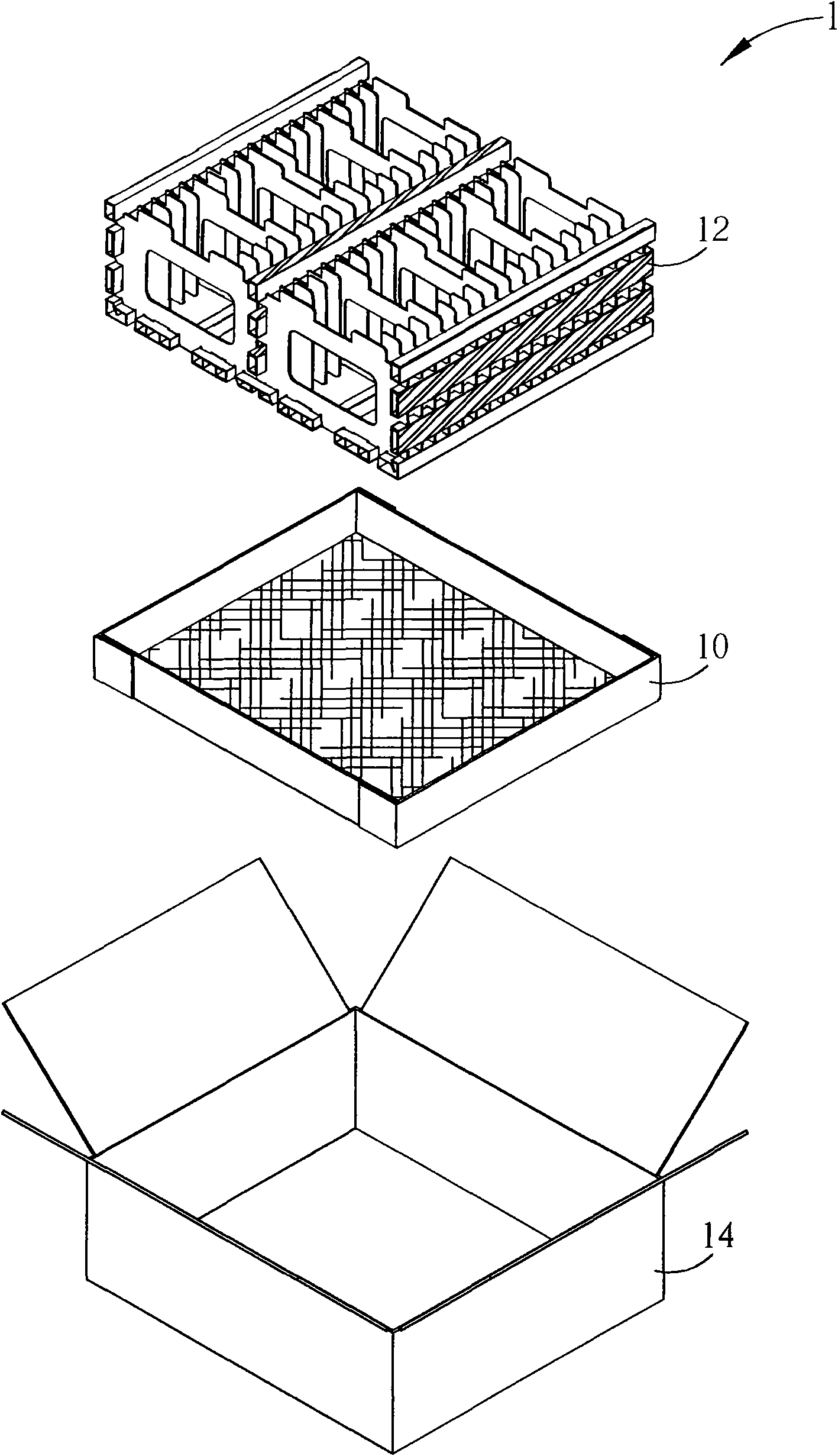

[0061] see Figure 4 to Figure 6 , Figure 4 It is a schematic diagram of a packing box according to an embodiment of the present invention, Figure 5 for Figure 4 The schematic diagram of opening the first cover and the second cover respectively in Image 6 for Figure 5 A schematic diagram of the engagement of the first cover and the partition in . Such as Figure 4 to Figure 6 As shown, the packing box 3 includes a box body 30 , a plurality of partitions 32 , a first cover 34 and a second cover 36 . The box body 30 includes a bottom panel 300 , a first side panel 302 and a second side panel 304 . The first side plate 302 and the second side plate 304 are respectively located on two sides of the bottom plate 300 , and a plurality of partition plates 32 are disposed between the first side plate 302 and the second side plate 304 . A first opening 306 and a second opening 308 are respectively interposed between the first side plate 302 and the second side plate 304, such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com