Diamond composite sheet matrix with carbon potential gradient

A diamond composite sheet and gradient technology, applied in drilling equipment, earthwork drilling, drill bits, etc., can solve problems affecting the performance and service life of diamond composite sheets, comprehensive performance reduction, carburization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention designs a cemented carbide matrix with a carbon potential gradient at the same time to reduce or eliminate the carburization of the matrix caused by the graphitization of the diamond at the composite interface between the diamond and the cemented carbide matrix, thereby ensuring that the diamond composite sheet has higher comprehensive performance .

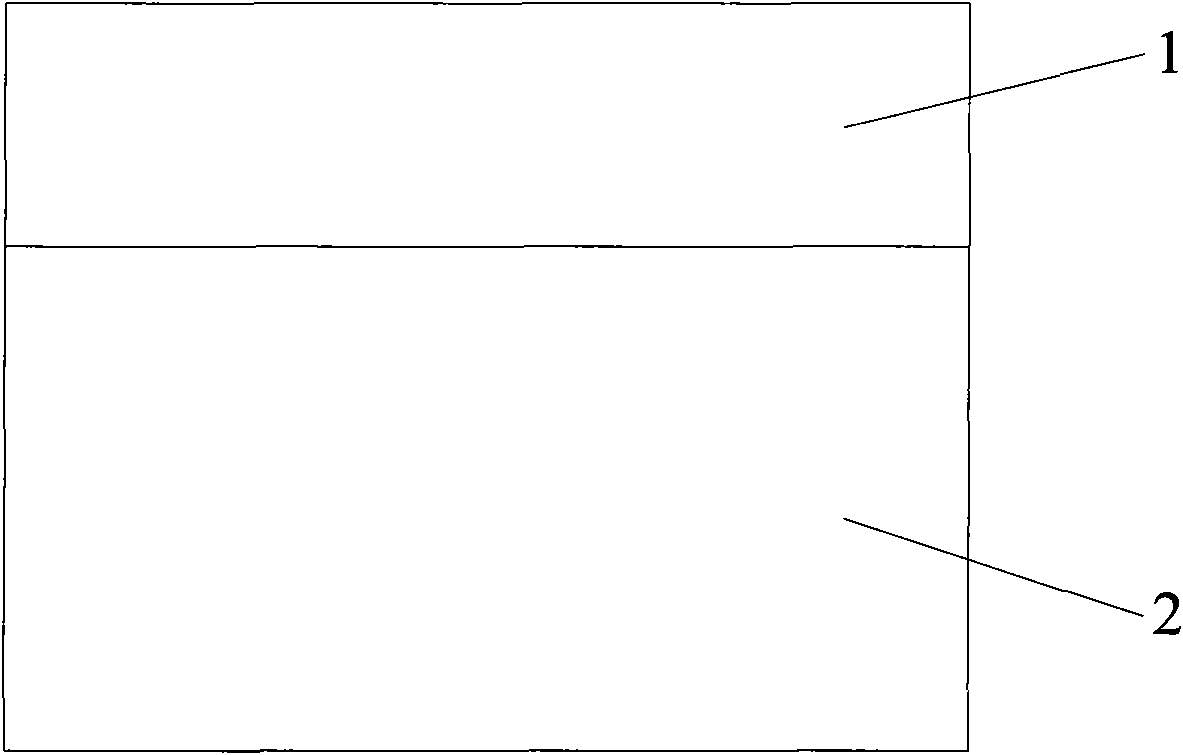

[0015] Such as figure 1 As shown, the diamond composite substrate with a carbon potential gradient has a double-layer structure, including an upper part 1 and a lower part 2 connected to it. The thickness of the upper part 1 is 1-4mm, and the thickness of the lower part 2 is 4-20mm. The composition of the lower part 2: cobalt accounts for 10% to 18% by weight, and tungsten carbide accounts for 82% to 90% by weight. Among them, the carbon balance of the upper part of tungsten carbide is 0.02 to 0.10% lower than that of the lower part. Potential gradient; the upper part of the matrix combined with diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com