Stitched seam structure, item of clothing comprising a stitched seam structure and method for producing a stitched seam structure

A technology for connecting structures and sutures, applied to household appliances, other household appliances, household components, etc., can solve problems such as porosity and leakage of sutures, and achieve the effects of high tear strength, material saving, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

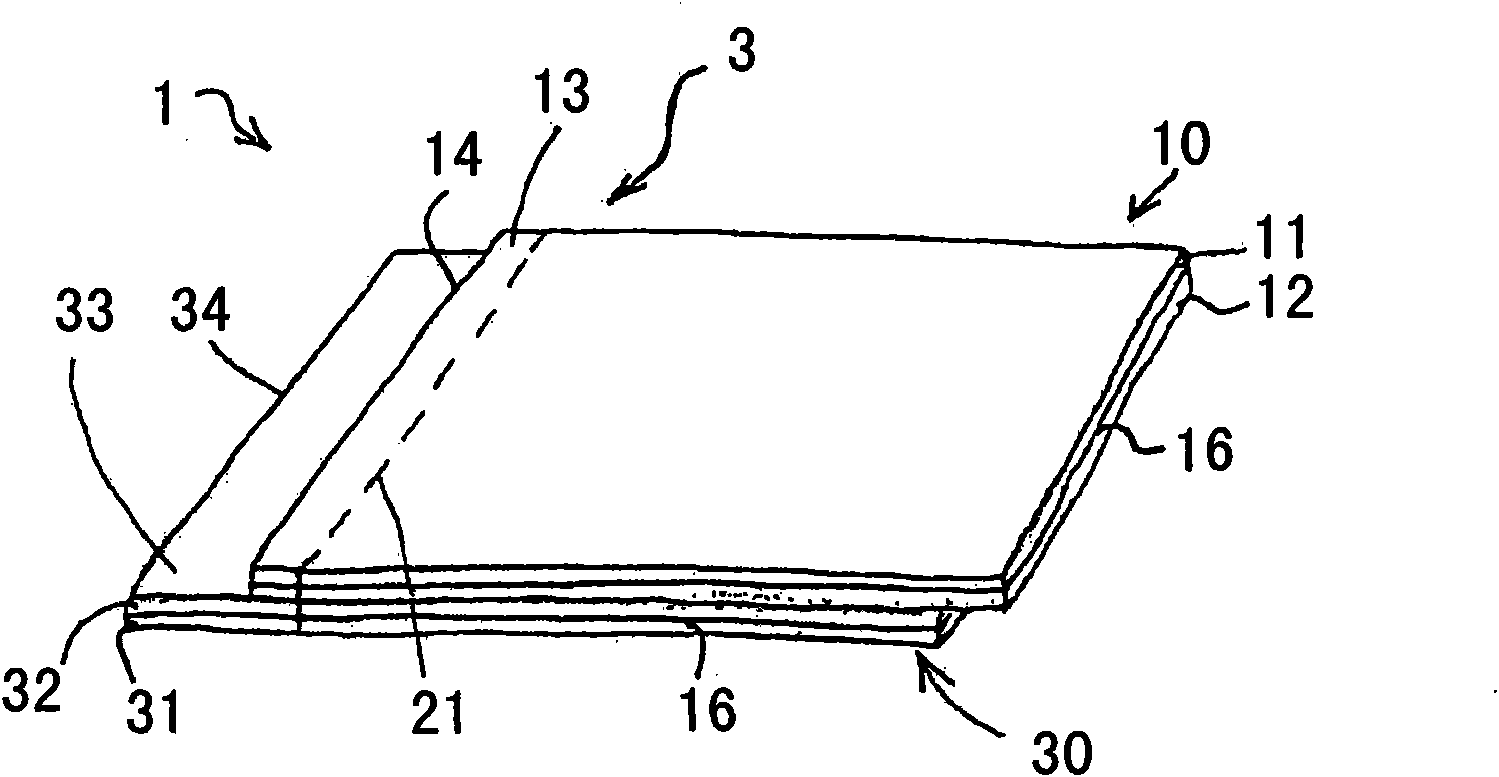

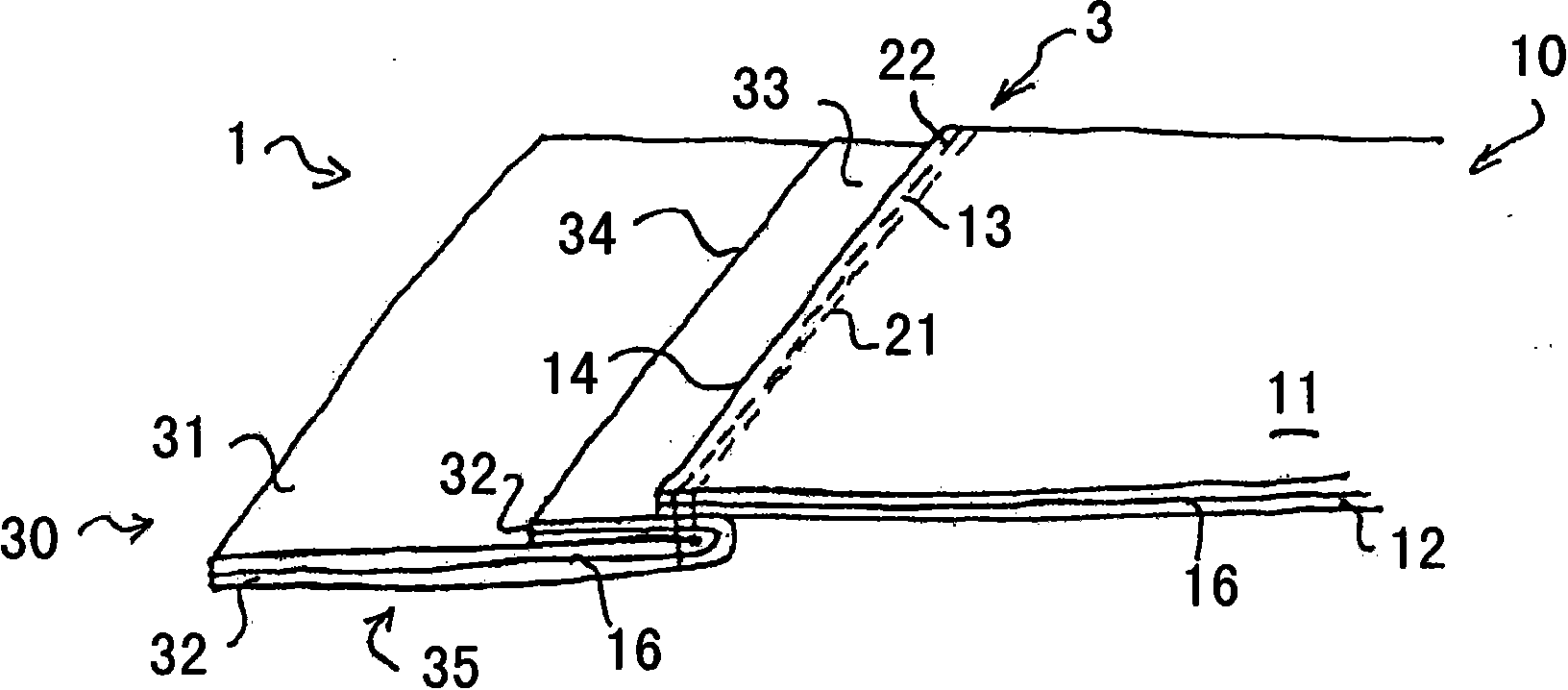

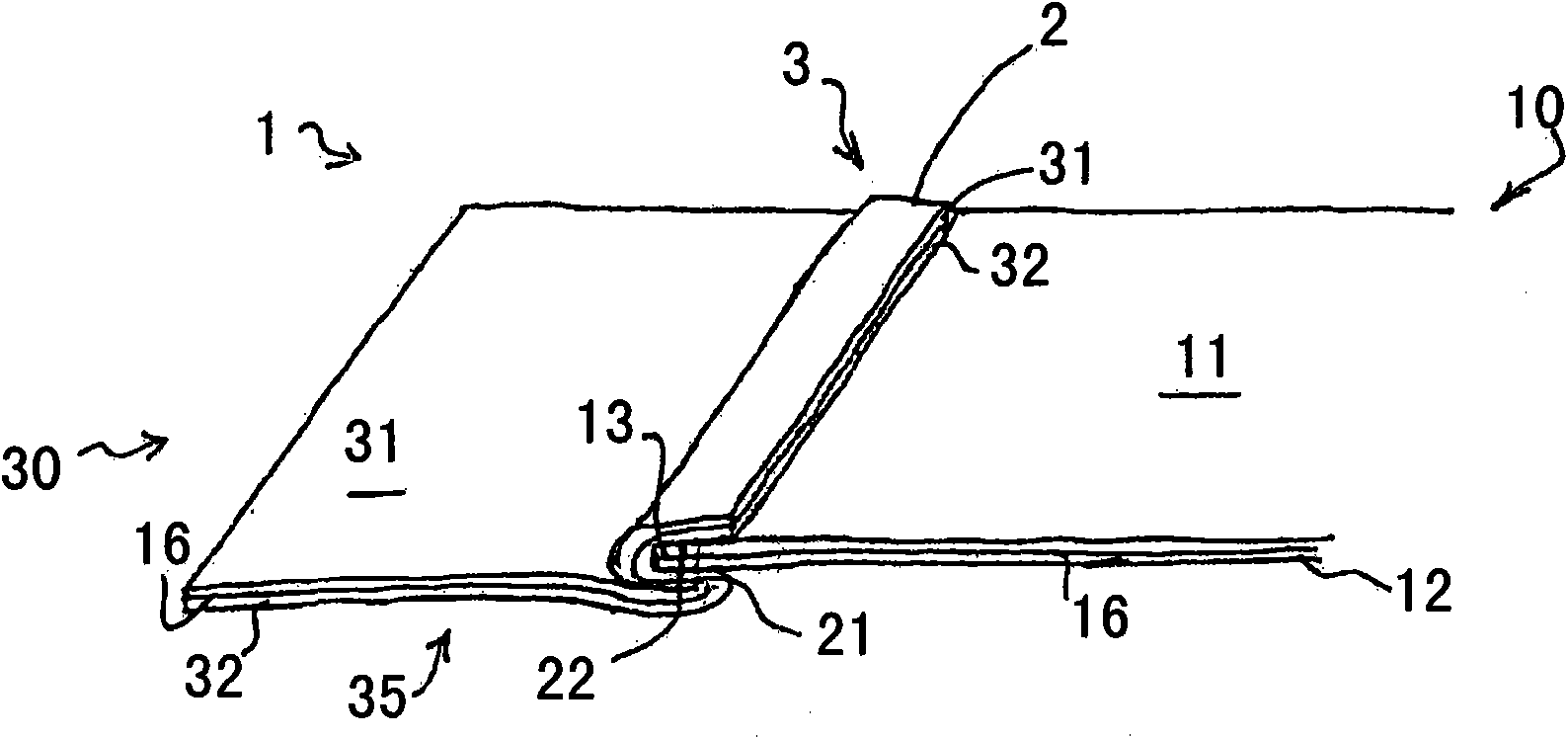

[0057] A three-layer laminate is provided to form a suture-connected structure. The three-layer laminate is a commercially available product sold by W.L. Gore & Associates GmbH of Putzbrunn, Germany under the trade name Gore Liquid Proof Gown Fabric). The laminate has a basis weight of 65g / m 2 The first layer of textile is polyester, and the basis weight is 50g / m 2 A second layer of polyester textile. A porous membrane of expandable PTFE (ePTFE) is arranged between two textile layers. The laminate has a 170g / m 2 The basis weight and the thickness of about 310-330μm.

[0058] The two fabrics of the 3-layer laminate are joined to each other to form a seam-joined structure according to the invention. According to the present invention, the first suture and the second suture are sewn with a commercial sewing machine. The width of the suture covering part 2 is about 10-15mm. In comparison, common suture tapes have suture widths between 22-23 mm. For the liquid-tight sealin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com