Method for biological treatment of rubber vulcanized tail gas

A technology of rubber vulcanization and biological treatment, which is applied in the direction of chemical instruments and methods, separation methods, and air quality improvement. It can solve the problems of low exhaust gas concentration and low exhaust gas purification efficiency, and achieve short processing time, reduce operating costs and management requirements. , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

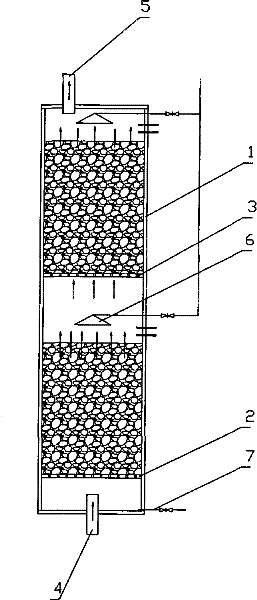

[0040] according to figure 1 The structure shown is used to build a biological filter, and the specific surface area of the nano-clay lightweight filler is selected as 50-150m 2 / cm 3 , use the spray head to spray water 2 to 3 times to the biofilm layer every day, each time for 5 to 10 minutes, so that the working temperature in the biofilter is kept at 3 to 5°C, the pH value is 5, and the humidity is kept at 60%.

[0041]The waste steam discharged from the vulcanization cylinder is decompressed through the expansion tank to about 1 atmospheric pressure, then passed into the heat exchanger and condenser to cool down to below 40°C, and then passed into the waste gas buffer chamber. The waste gas in the waste gas buffer chamber is The fan extracts and passes into the waste gas intake hole at the bottom of the biological filter. The waste water from the vulcanization tank is passed into the anaerobic pool, the cooling water in the waste gas buffer chamber is passed into the a...

Embodiment 2

[0043] according to figure 1 The structure shown is used to build a biological filter, and the specific surface area of the nano-clay lightweight filler is selected as 50-150m 2 / cm 3 , use the spray head to spray water to the biofilm layer 2 to 3 times a day, each time for 5 to 10 minutes, so that the working temperature in the biofilter is kept at 10 to 15°C, the pH value is 5.5, and the humidity is kept at 70%.

[0044] The waste steam discharged from the vulcanization cylinder is decompressed through the expansion tank to about 1 atmospheric pressure, then passed into the heat exchanger and condenser to cool down to below 40°C, and then passed into the waste gas buffer chamber. The waste gas in the waste gas buffer chamber is The fan extracts and passes into the waste gas intake hole at the bottom of the biological filter. The waste water from the vulcanization tank is passed into the anaerobic pool, the cooling water in the waste gas buffer chamber is passed into the ...

Embodiment 3

[0046] according to figure 1 The structure shown is used to build a biological filter, and the specific surface area of the nano-clay lightweight filler is selected as 50-150m 2 / cm 3 , use the spray head to spray water to the biofilm layer 2 to 3 times a day, 5 to 10 minutes each time, so that the working temperature in the biofilter is kept at 35 to 40°C, the pH value is 8, and the humidity is kept at 85%.

[0047] The waste steam discharged from the vulcanization cylinder is decompressed through the expansion tank to about 1 atmospheric pressure, and then passed into the heat exchanger to cool down to 40°C, and then passed into the waste gas buffer chamber, and the waste gas in the waste gas buffer chamber is extracted by the fan. And pass into the waste gas intake hole at the bottom of the biological filter. The waste water from the vulcanization tank is passed into the anaerobic pool, the cooling water in the waste gas buffer chamber is passed into the anaerobic pool,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com