The preparation method of block copolymer mpeg-b-pla

A block copolymer, mpeg-b-pla technology, applied in the field of block copolymer mPEG-b-PLA preparation, can solve the problem of difficult control of product molecular weight and molecular weight distribution, difficulty in stable control of polymerization conditions, and low production efficiency And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A preparation method of block copolymer mPEG-b-PLA, comprising the following steps:

[0037] (1) Raw material processing: Weigh polyethylene glycol monomethyl ether and lactide, dissolve polyethylene glycol monomethyl ether in a volatile organic solvent, remove water, filter for later use; recrystallize lactide, and dry Standby; Wherein, polyethylene glycol monomethyl ether: the weight ratio of lactide is (0.1~30): 1; Described volatile organic solvent selects the alkane of low carbon chain or substituted alkane, and described carbon chain length is C 1 -C 10 .

[0038] (2) Synthesis of mPEG-b-PLA: polyethylene glycol monomethyl ether and lactide are dissolved with volatile organic solvents respectively to obtain polyethylene glycol monomethyl ether solution and lactide solution. The preferred low-carbon chain alkane or substituted alkane of the organic solvent, the carbon chain length is C 1 -C 10 . Next, add amidine catalyst to the polyethylene glycol monomethyl ...

Embodiment 1

[0044] Embodiment 1, a kind of preparation method of block copolymer mPEG-b-PLA (mPEG1000-b-PLA9000), comprises the following steps:

[0045] (1) Raw material treatment: take polyethylene glycol monomethyl ether (PEG1000) and lactide as raw materials, dissolve polyethylene glycol monomethyl ether in dichloromethane, remove water with molecular sieves, and filter for later use; The ester was recrystallized twice with ethanol and dried for later use;

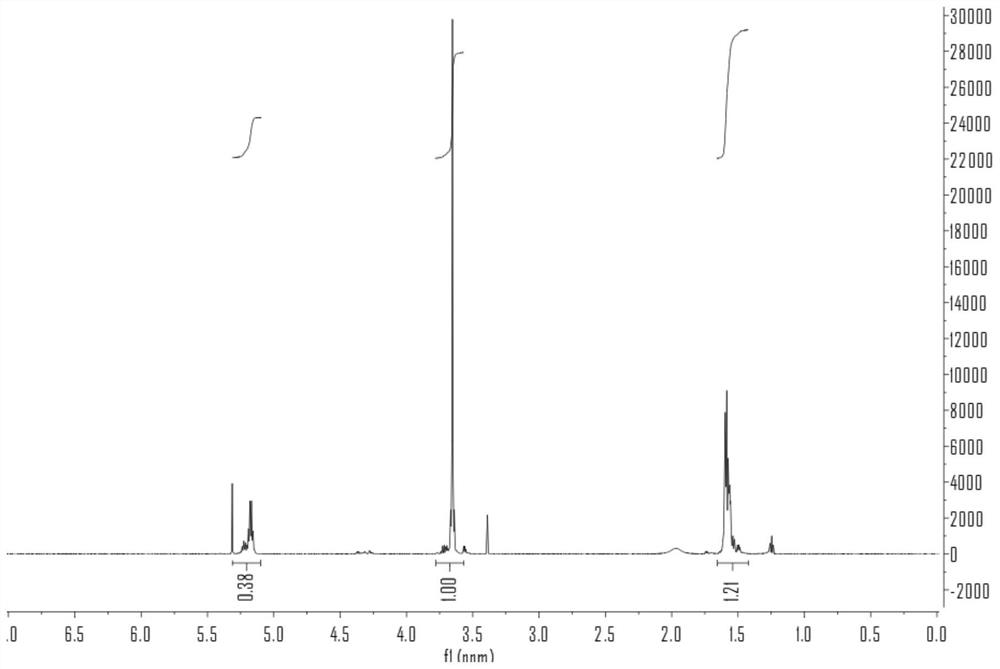

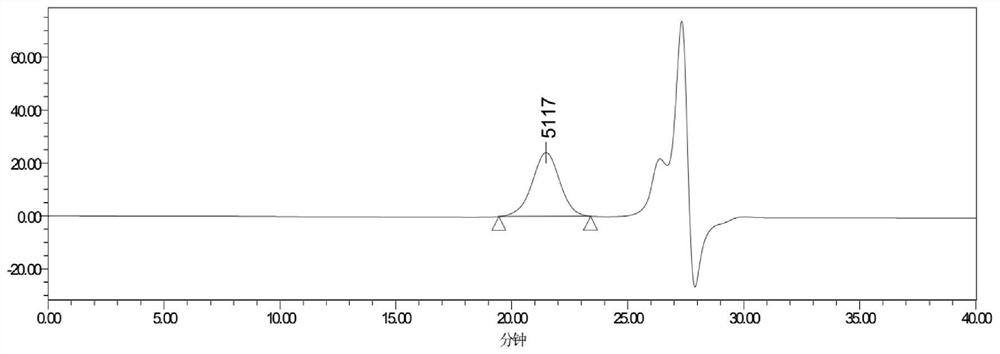

[0046] (2) Synthesis of mPEG-b-PLA: Dissolve pretreated 1g mPEG1000 in 50mL dichloromethane, stir at 500r / min to obtain mPEG1000 solution, add 240μL DBN; dissolve 9g lactide in 50mL dichloromethane to obtain lactide solution, and then the lactide solution was transferred to the mPEG1000 solution, the air was removed, and the vacuum degree was 0.1Mpa. After reacting for 180 minutes, 110 μl of glacial acetic acid was added to terminate the reaction, and the stirring was continued for 10 minutes. The crude product was obtained after ...

Embodiment 2

[0049] Embodiment 2, a kind of preparation method of block copolymer mPEG-b-PLA (mPEG1000-b-PLA3000), comprises the following steps:

[0050] (1) Raw material treatment: take polyethylene glycol monomethyl ether (PEG1000) and lactide as raw materials, dissolve polyethylene glycol monomethyl ether in dichloromethane, remove water with molecular sieves, and filter for later use; The ester was recrystallized twice with ethanol and dried for later use, wherein the weight ratio of polyethylene glycol monomethyl ether: lactide was 1:3.

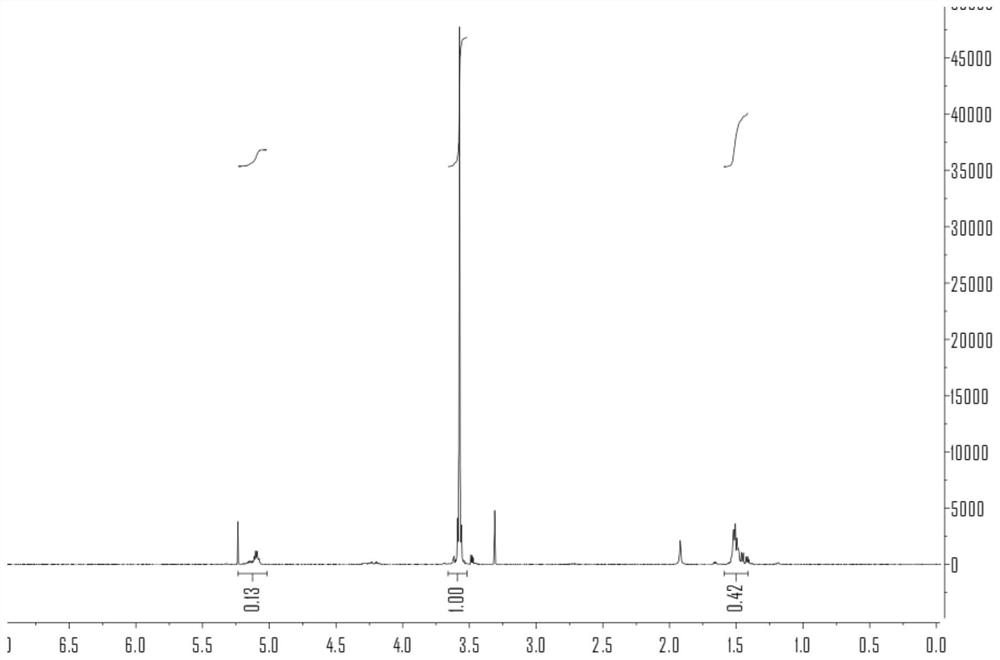

[0051] (2) Synthesis of mPEG-b-PLA: pretreated 2g mPEG1000 was dissolved in 50mL dichloromethane, stirred at 500r / min to obtain mPEG1000 solution, 130μg TBD was added; 6g lactide was dissolved in 50mL dichloromethane to obtain lactide solution, and then the lactide solution was transferred to the mPEG1000 solution, the air was removed, and the vacuum degree was 0.09Mpa to react for 30 minutes; 89 μg of benzoic acid was added to terminate the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com