Automatic welding machine for automobile main beams

An automatic welding machine and main beam technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low work efficiency, high labor intensity of operators, and poor welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

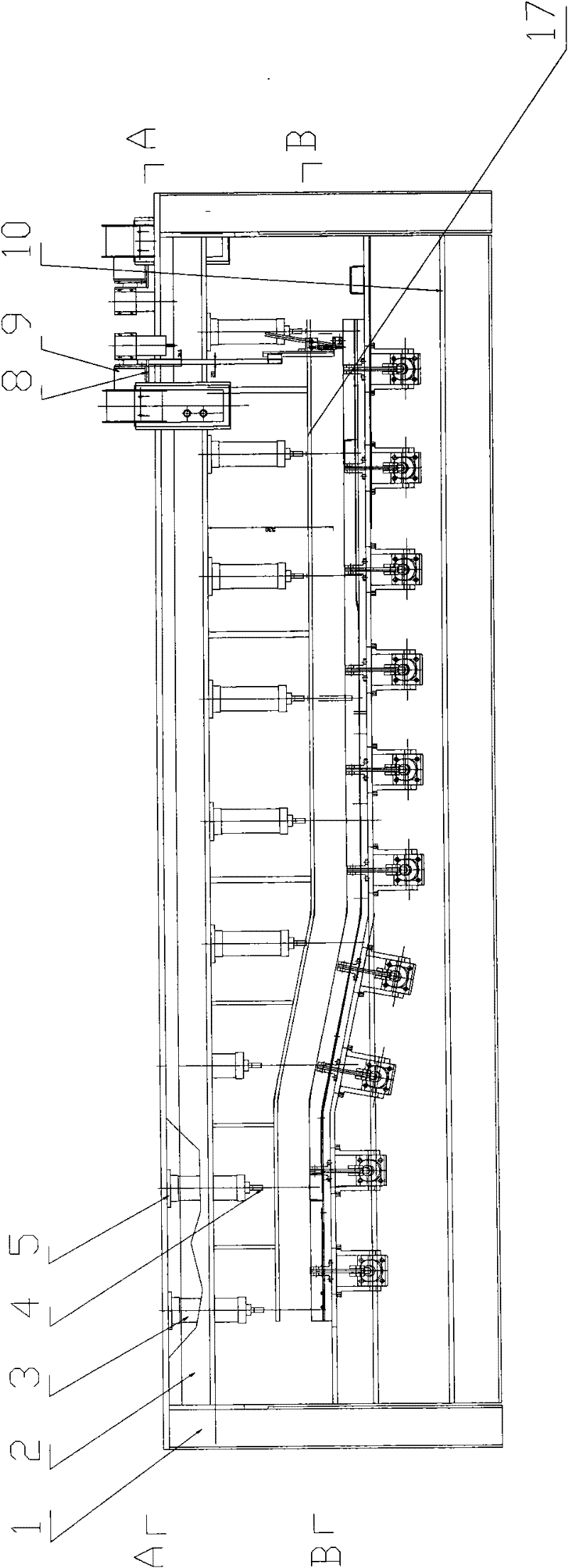

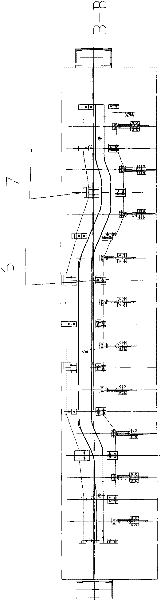

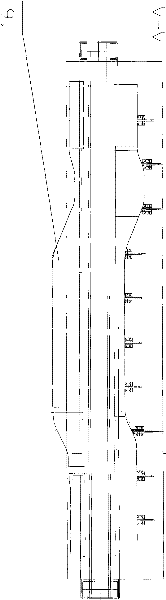

[0016] As shown in Fig. 14, the automatic main beam welding machine provided by the present invention is used for welding the inner plate and outer plate of the main beam of various automobile frames such as SUV cars and pickup trucks. Using two CO 2 The shielded welding machine is used to weld the left and right two seams respectively. The main technology of automatic welding is to make the welding torch produce precise trajectory and move at a uniform speed during welding. Its structure and working principle are as follows:

[0017] The automatic welding machine includes a frame composed of a column assembly, an upper beam assembly 1, and a lower beam assembly 10. It is characterized in that a set of laterally moving cams 16 and a set of vertically moving cams 17 are installed on the upper beam assembly; The lower beam assembly is equipped with a set of air cylinders or hydraulic cylinders and a set of toggle mechanisms to form a lateral clamping device; the upper beam ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com