Sink roll scraper mechanism

A scraper device and submerged roller technology, applied in coating, metal material coating process, hot dip plating process, etc., can solve the problem of not being able to stick to the roller surface, so as to improve the slag scraping effect, improve the surface quality, reduce the The effect of small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

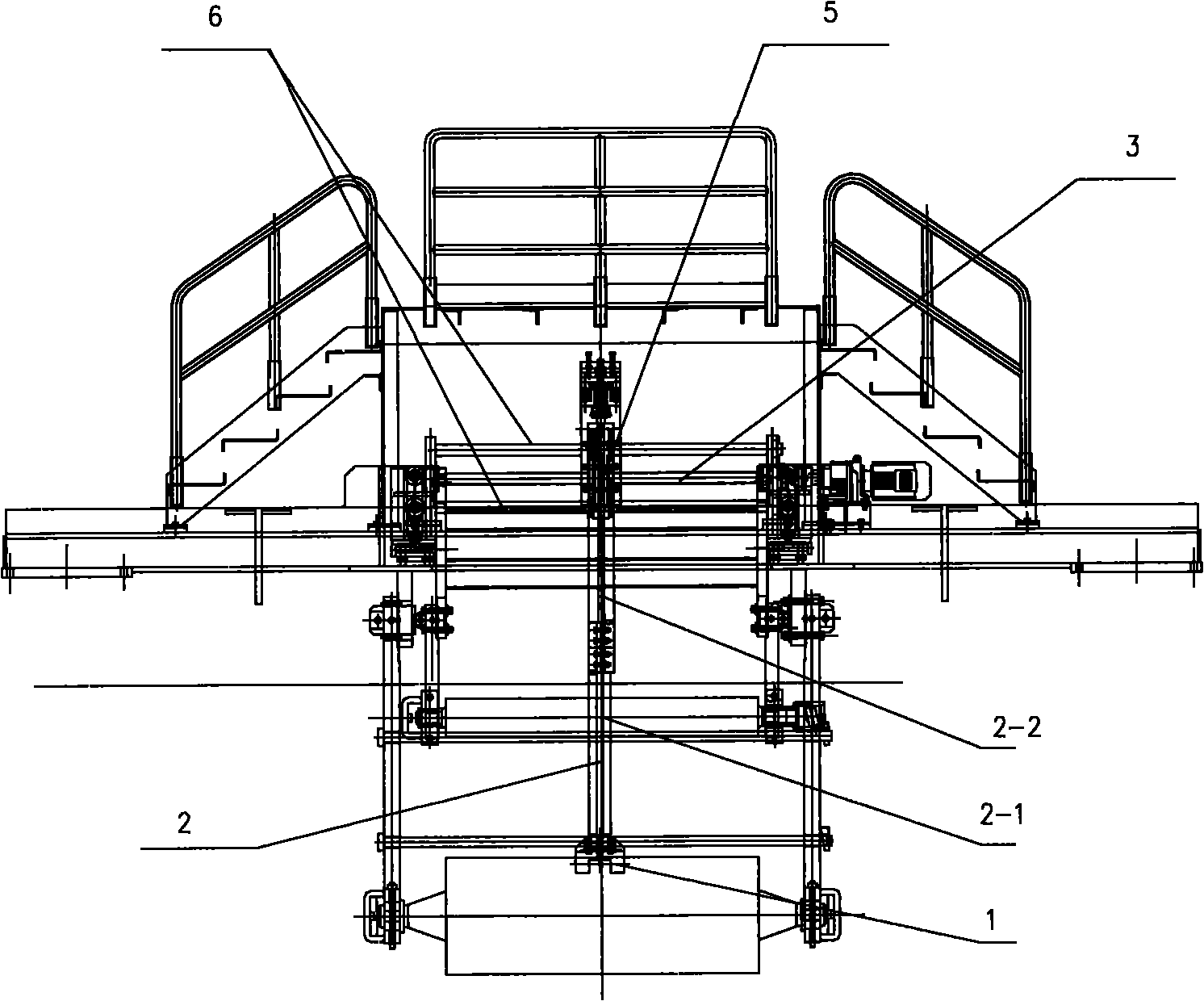

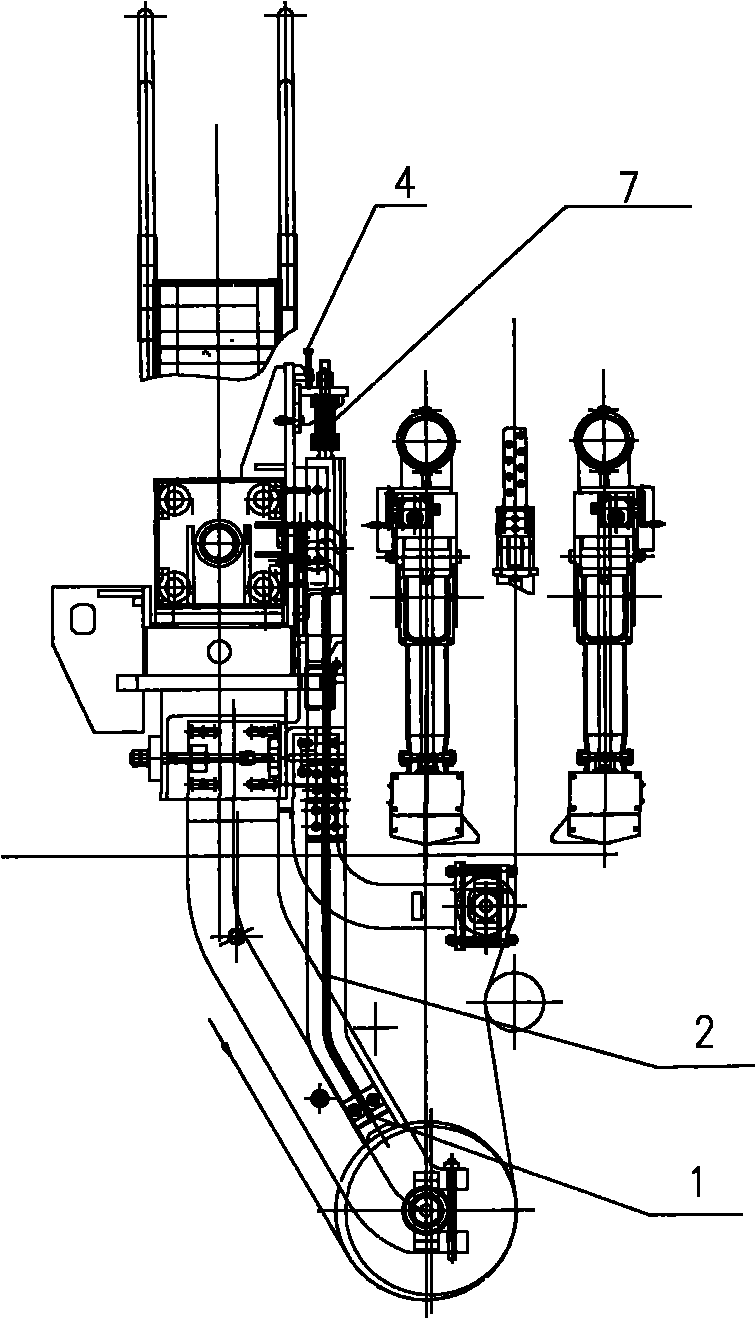

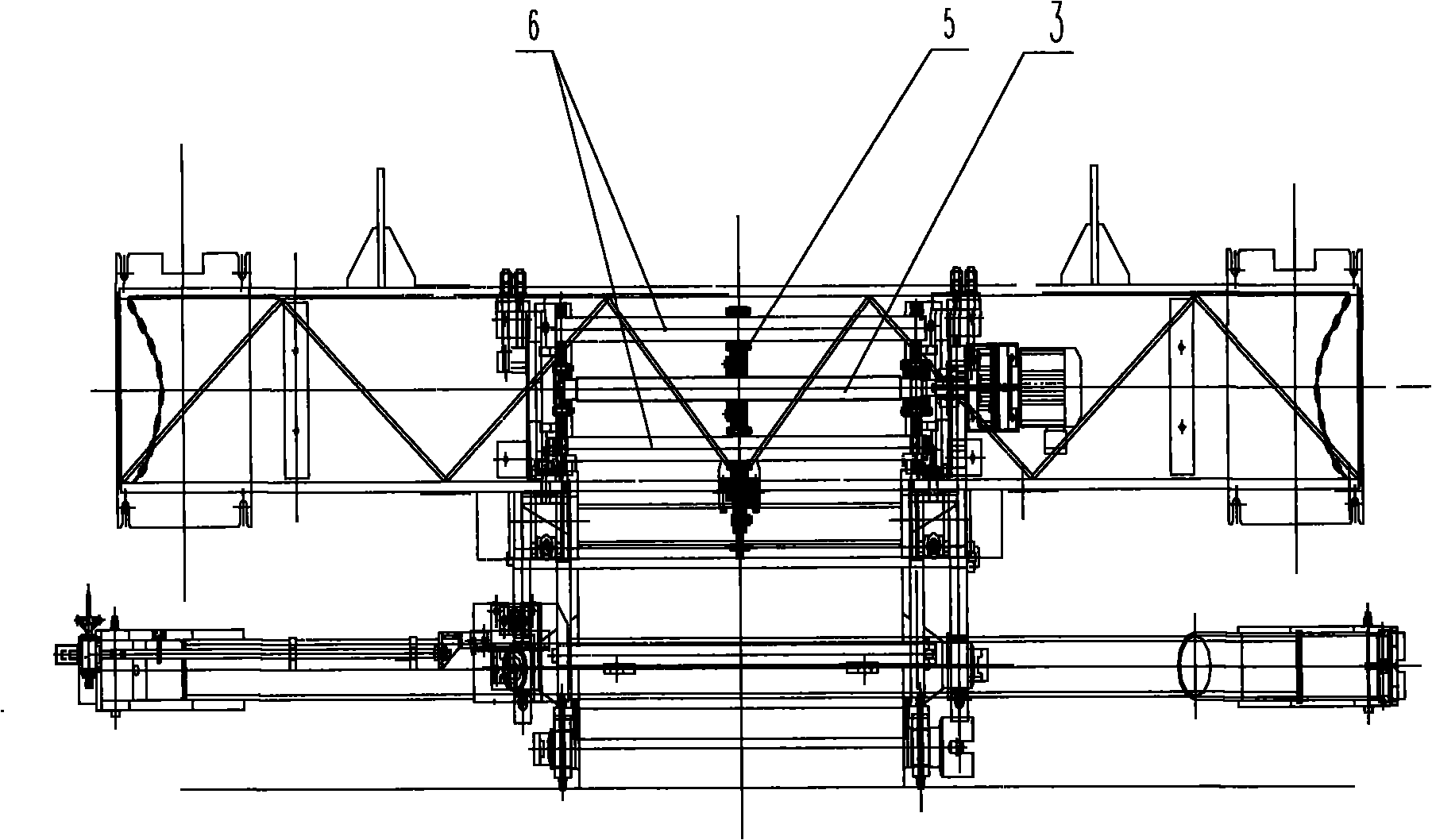

[0022] Examples, see figure 1 , figure 2 , image 3 , a scraper device for a sinking roller, comprising a sinking roller beam and a scraper 1, the scraper 1 is in longitudinal contact with the sinking roller surface and is connected with a screw 3 arranged on the sinking roller beam through a connecting rod 2, and the rotation of the screw 3 drives the scraper 1 Move along the axial direction of the sinking roller to scrape off the zinc slag on the sinking roller, and the connecting rod 2 is provided with an adjusting screw 4 for adjusting the distance between the scraper 1 and the surface of the sinking roller;

[0023] The connecting rod 2 includes a scraper connecting rod 2-1 and an adjusting connecting rod 2-2. The lower end of the scraping connecting rod 2-1 is connected to the scraper 1, the upper end is connected to the lower end of the adjusting connecting rod 2-2, and the adjusting connecting rod 2-2 The upper end is connected with the screw rod 3, the scraper conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com