Differential thermal-gas chromatography combined analysis device

A technology of gas chromatography and analysis equipment, which is applied in the field of batch coupling equipment and differential thermal-gas chromatography coupling analysis equipment, and can solve the problems that are not suitable for automatic operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

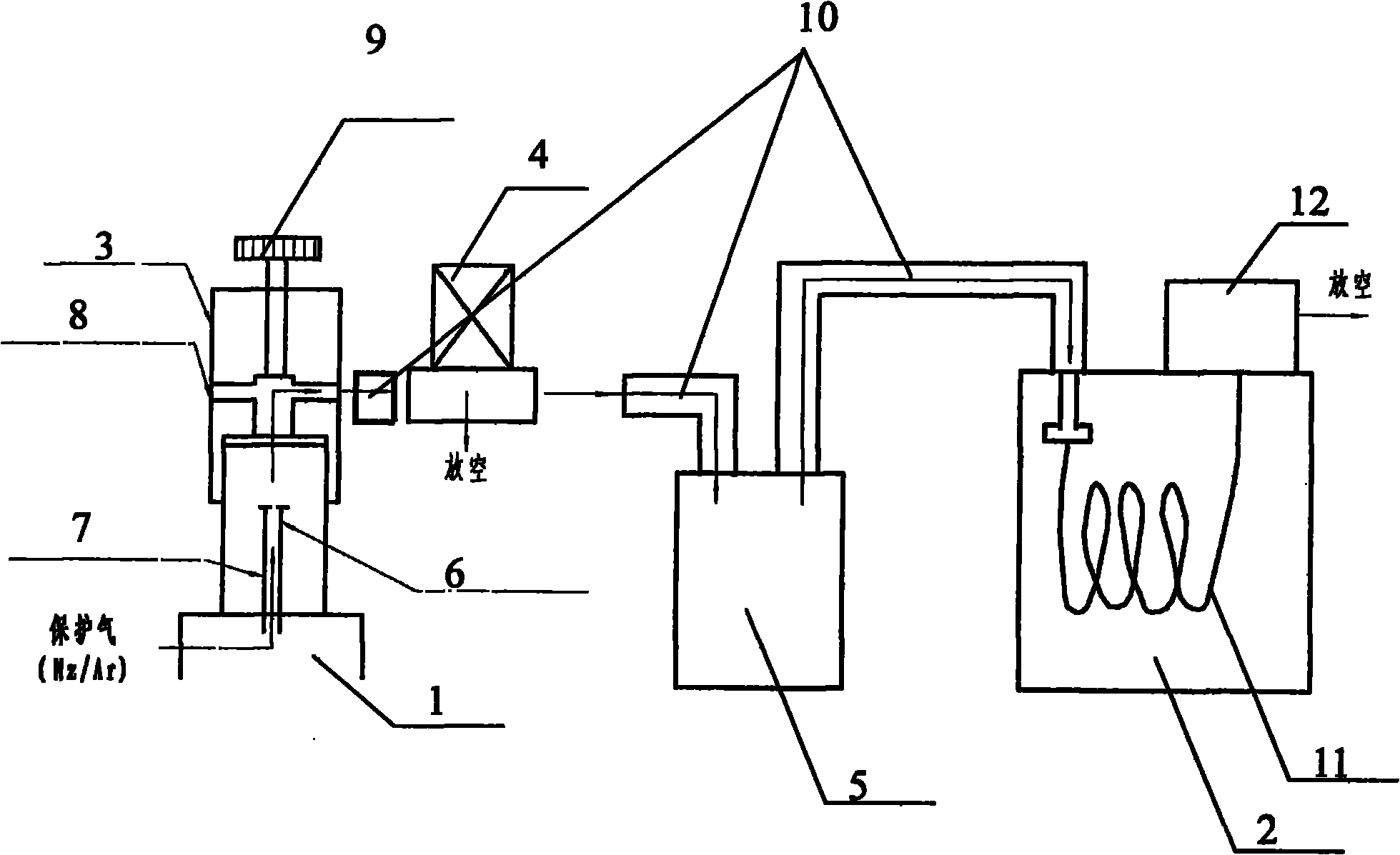

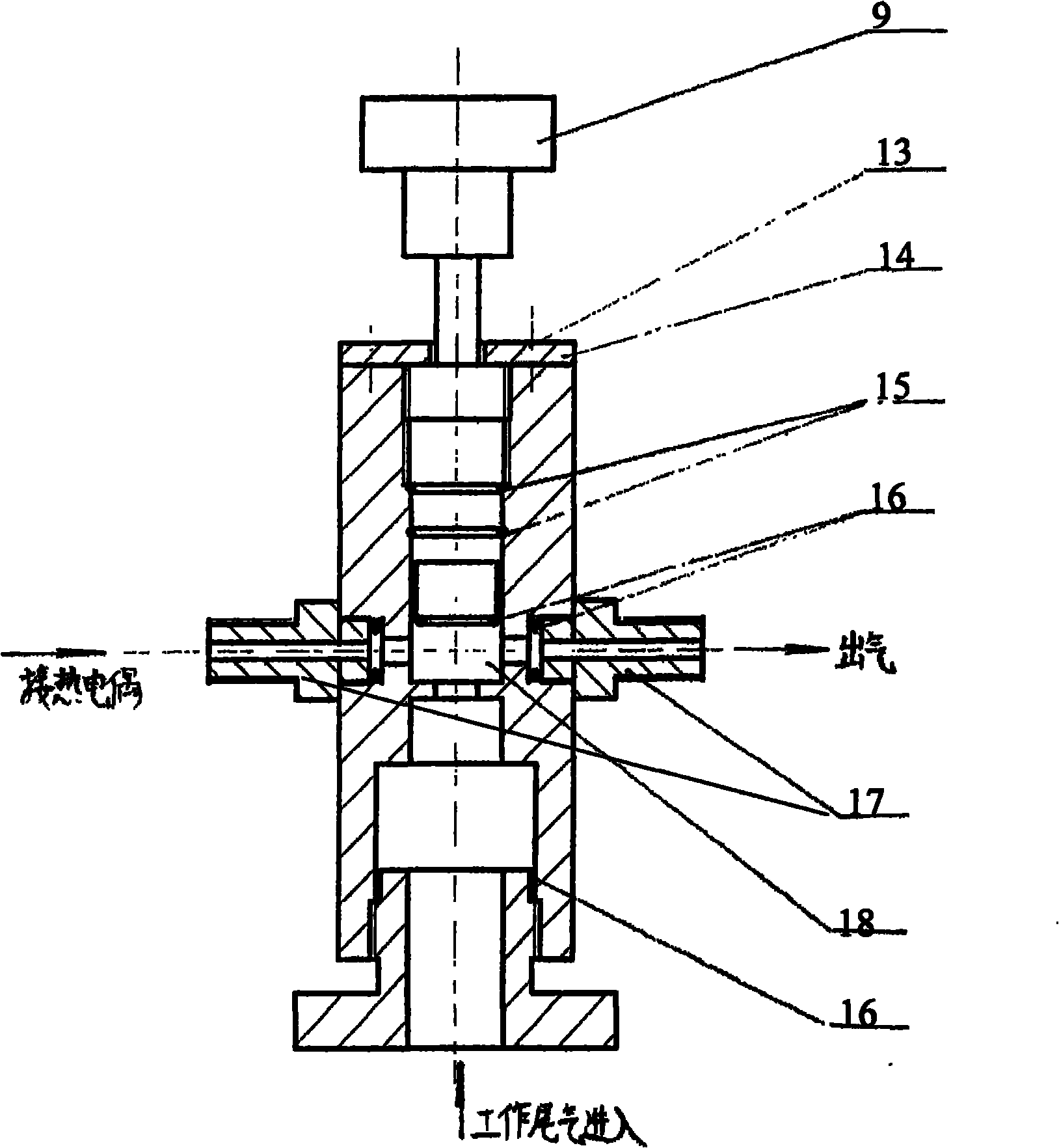

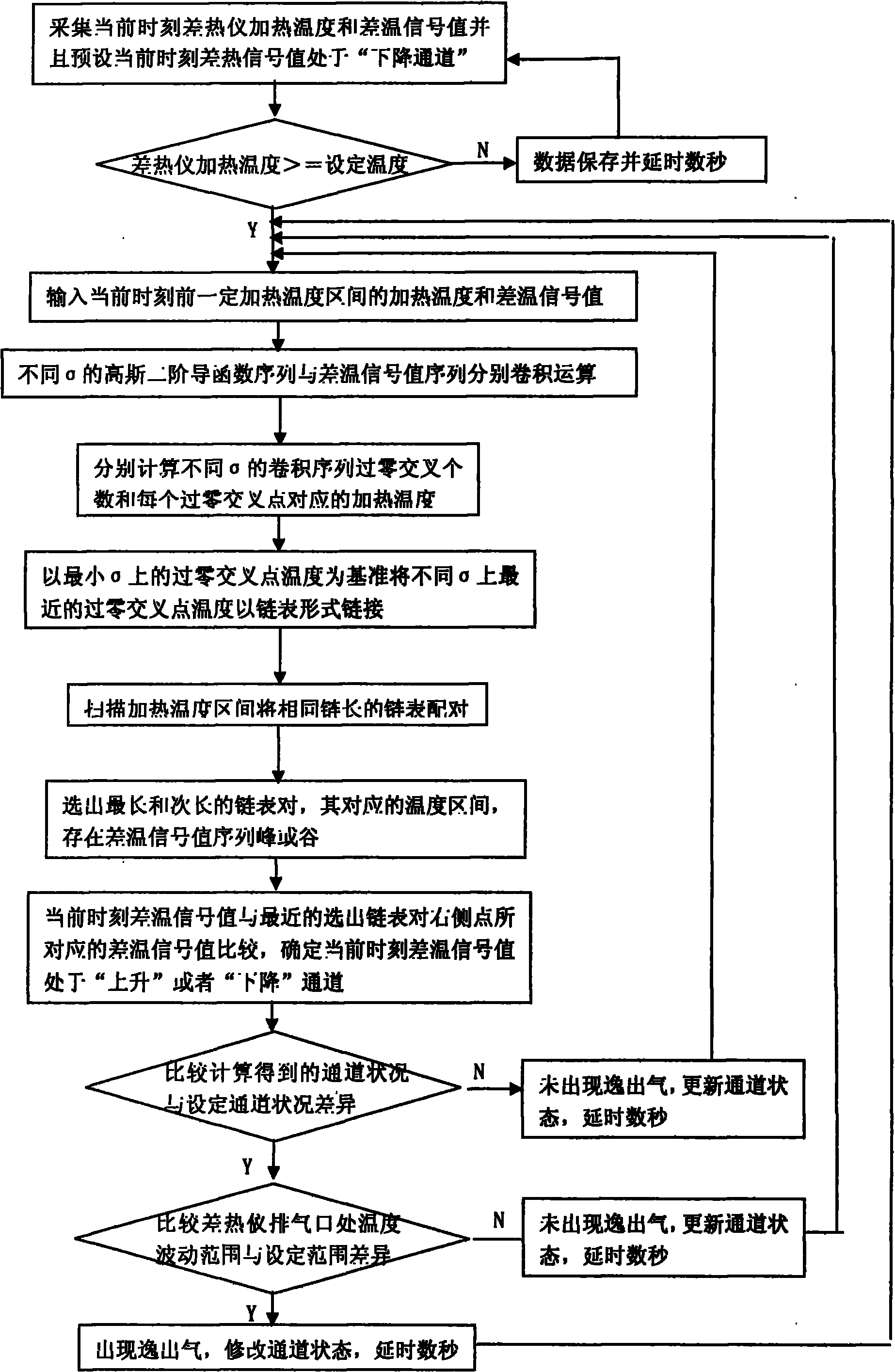

[0046] The example of this matter is based on the traditional differential thermal-gas chromatography intermittent coupling analysis device, adding gas sampling components 3, automatic air intake control mechanism, and using the computer to collect the differential thermal signal of the differential thermal analyzer 1, the furnace temperature signal and The temperature signal at the outlet point 8 of the exhaust gas of the differential thermal analyzer 1 is predicted and judged by the time series curve of these signals to judge whether there is escaped gas in the exhaust gas of the differential thermal analyzer 1, and the top is automatically opened after the escaped gas is found. The empty sampling device is used to introduce the quantitative tail gas into the gas chromatograph 2 for component separation and detection. This combined analysis device can realize automatic operation and is suitable for operation in an unattended environment.

[0047] Combine below Figure 1-Fig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap