Latch needle for circular knitting machine

A circular knitting machine and latch needle technology, applied in the latch needle field, can solve problems such as difficult processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

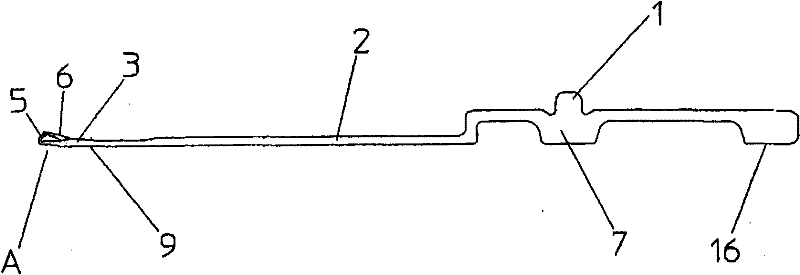

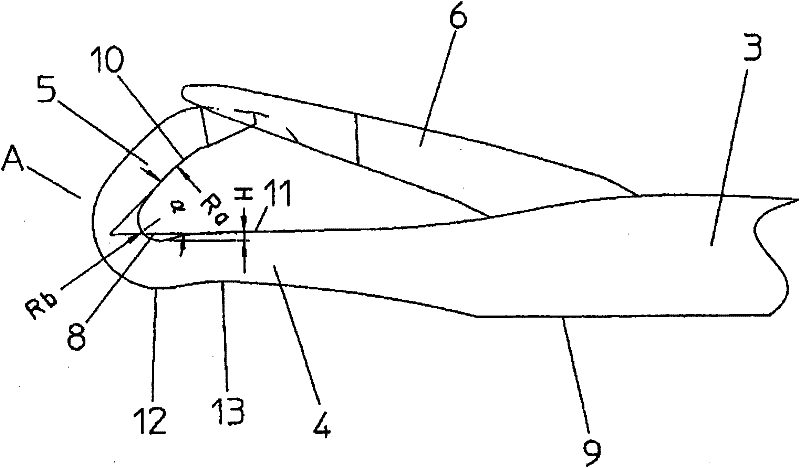

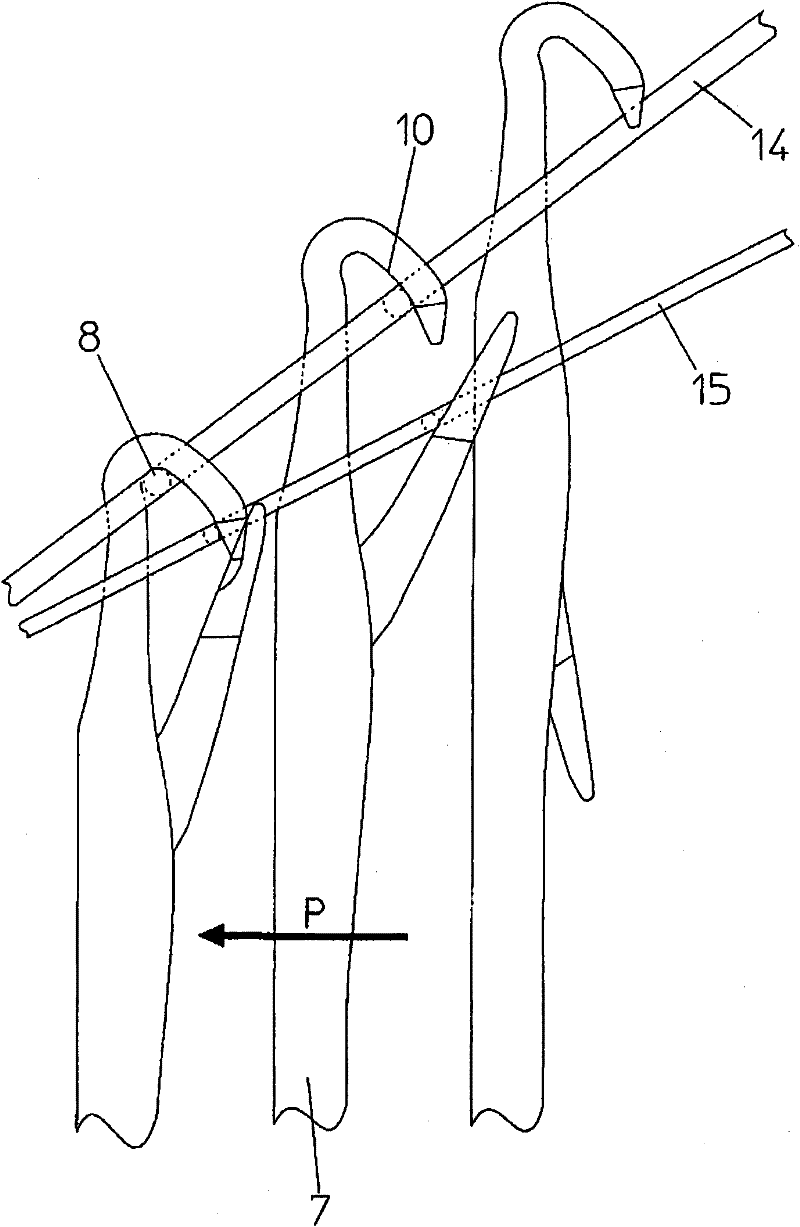

[0023] figure 1 It is an overall view of the latch needle 7 of the first embodiment of the present invention. figure 2 is an enlarged view of its hook. image 3 It is a perspective view showing the knitting process using the latch needle.

[0024] Such as figure 1 As shown, the latch needle 7 of the present invention is also the same as the conventional latch needle, and is provided with a needle portion A, a shank portion 2, at least one stitch 1, and a needle rear end portion 16 as basic structural components.

[0025] Such as figure 2 As shown, the needle part A includes: a needle hook 5; a needle latch 6 for opening and closing the needle hook 5; a needle cheek 3 pivotally supporting the needle latch 6; a connecting part 4 connecting the needle cheek 3 and the needle hook 5 . The connecting part 4 is located slightly higher than the needle back 9 .

[0026] The present invention is characterized in that a recess 8 is provided between the connecting portion 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com